Manufacturing is evolving through two key approaches: servitization and customization, each enhancing value for customers in distinct ways. Servitization integrates services with products to create comprehensive solutions, while customization tailors products to individual specifications for unique customer needs. Explore how these strategies are transforming the manufacturing landscape and driving innovation.

Why it is important

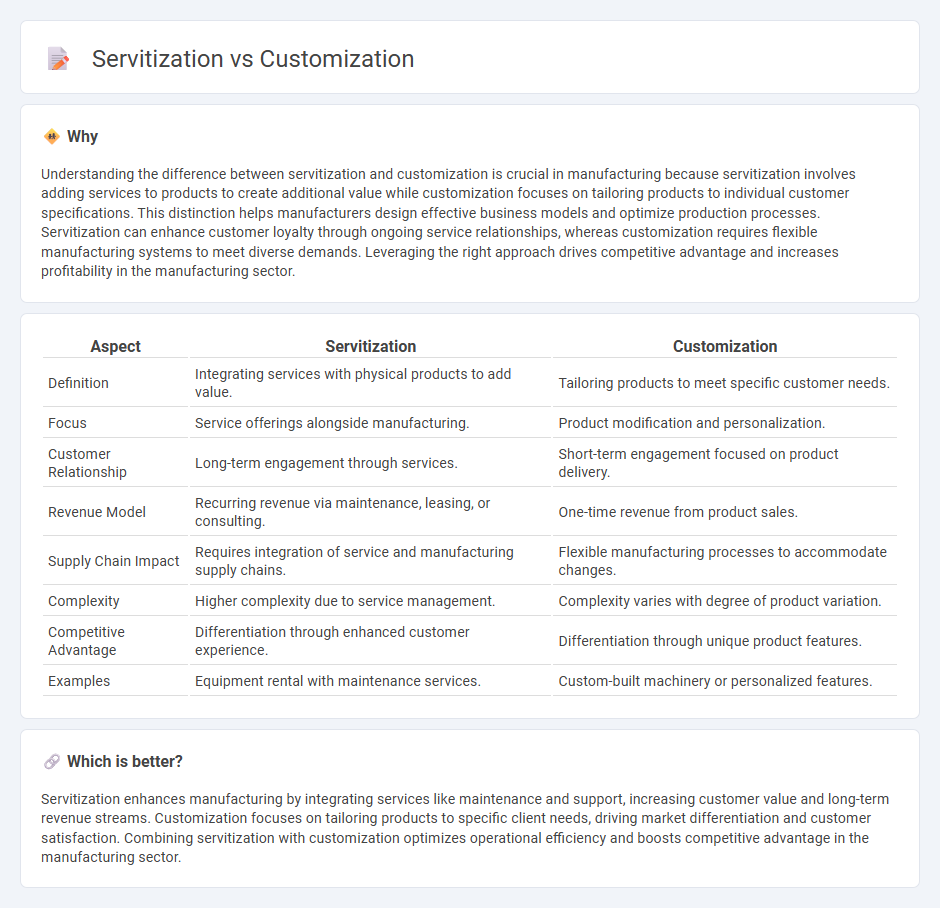

Understanding the difference between servitization and customization is crucial in manufacturing because servitization involves adding services to products to create additional value while customization focuses on tailoring products to individual customer specifications. This distinction helps manufacturers design effective business models and optimize production processes. Servitization can enhance customer loyalty through ongoing service relationships, whereas customization requires flexible manufacturing systems to meet diverse demands. Leveraging the right approach drives competitive advantage and increases profitability in the manufacturing sector.

Comparison Table

| Aspect | Servitization | Customization |

|---|---|---|

| Definition | Integrating services with physical products to add value. | Tailoring products to meet specific customer needs. |

| Focus | Service offerings alongside manufacturing. | Product modification and personalization. |

| Customer Relationship | Long-term engagement through services. | Short-term engagement focused on product delivery. |

| Revenue Model | Recurring revenue via maintenance, leasing, or consulting. | One-time revenue from product sales. |

| Supply Chain Impact | Requires integration of service and manufacturing supply chains. | Flexible manufacturing processes to accommodate changes. |

| Complexity | Higher complexity due to service management. | Complexity varies with degree of product variation. |

| Competitive Advantage | Differentiation through enhanced customer experience. | Differentiation through unique product features. |

| Examples | Equipment rental with maintenance services. | Custom-built machinery or personalized features. |

Which is better?

Servitization enhances manufacturing by integrating services like maintenance and support, increasing customer value and long-term revenue streams. Customization focuses on tailoring products to specific client needs, driving market differentiation and customer satisfaction. Combining servitization with customization optimizes operational efficiency and boosts competitive advantage in the manufacturing sector.

Connection

Servitization transforms manufacturing by integrating services such as maintenance, support, and consulting into product offerings, enhancing customer value and differentiating companies in competitive markets. Customization tailors products and services to meet specific customer needs, increasing satisfaction and loyalty while generating higher revenue streams. The connection lies in delivering personalized service-based solutions that rely on adaptable manufacturing processes and real-time data analytics to optimize efficiency and responsiveness.

Key Terms

Mass Customization

Mass customization integrates the efficiency of mass production with tailored product variations to meet individual customer needs, enhancing market responsiveness and consumer satisfaction. This approach contrasts with servitization, which shifts the business model from selling products to offering comprehensive service solutions, emphasizing ongoing customer relationships. Discover how mass customization can revolutionize your manufacturing strategy and drive competitive advantage.

Product-Service Systems

Product-Service Systems (PSS) integrate customization by tailoring products and services to individual customer needs, enhancing user experience and satisfaction. Servitization transforms traditional manufacturing firms into providers of comprehensive solutions, combining product sales with ongoing service offerings. Explore how leveraging PSS can drive competitive advantage through innovative business models and customer-centric approaches.

Value-added Services

Customization tailors products to meet individual customer preferences, enhancing satisfaction by addressing specific needs, while servitization integrates value-added services such as maintenance, training, and support to create comprehensive solutions that drive long-term customer loyalty and revenue streams. Companies adopting servitization shift from purely product sales to service-oriented business models, leveraging digital tools and data analytics to optimize service delivery and predict customer needs. Explore how combining customization with servitization transforms competitive advantage and customer experience in your industry.

Source and External Links

Customization: What It Is, Why Needed & How It Works - Customization is the process of altering a mass-produced product or service to meet the individual needs and preferences of a specific customer, which enhances competitiveness, efficiency, profits, customer relationships, and brand recognition.

What Is Customization? - Storyly - Customization involves designing products and services with flexibility to suit individual preferences, leveraging technology like CRM and 3D printing to enable personalized alterations efficiently.

Personalization vs Customization: What's the Difference? - Acquire.io - Customization differs from personalization in that customers actively modify products or services themselves, such as changing product color or software plans, while personalization uses customer data to tailor experiences automatically.

dowidth.com

dowidth.com