Green steel production uses hydrogen or electric arc furnaces powered by renewable energy to minimize carbon emissions, offering a sustainable alternative to traditional steelmaking. Recycled steel, derived from scrap metal, reduces raw material consumption and energy usage while maintaining material quality. Discover how these innovative methods shape the future of eco-friendly manufacturing.

Why it is important

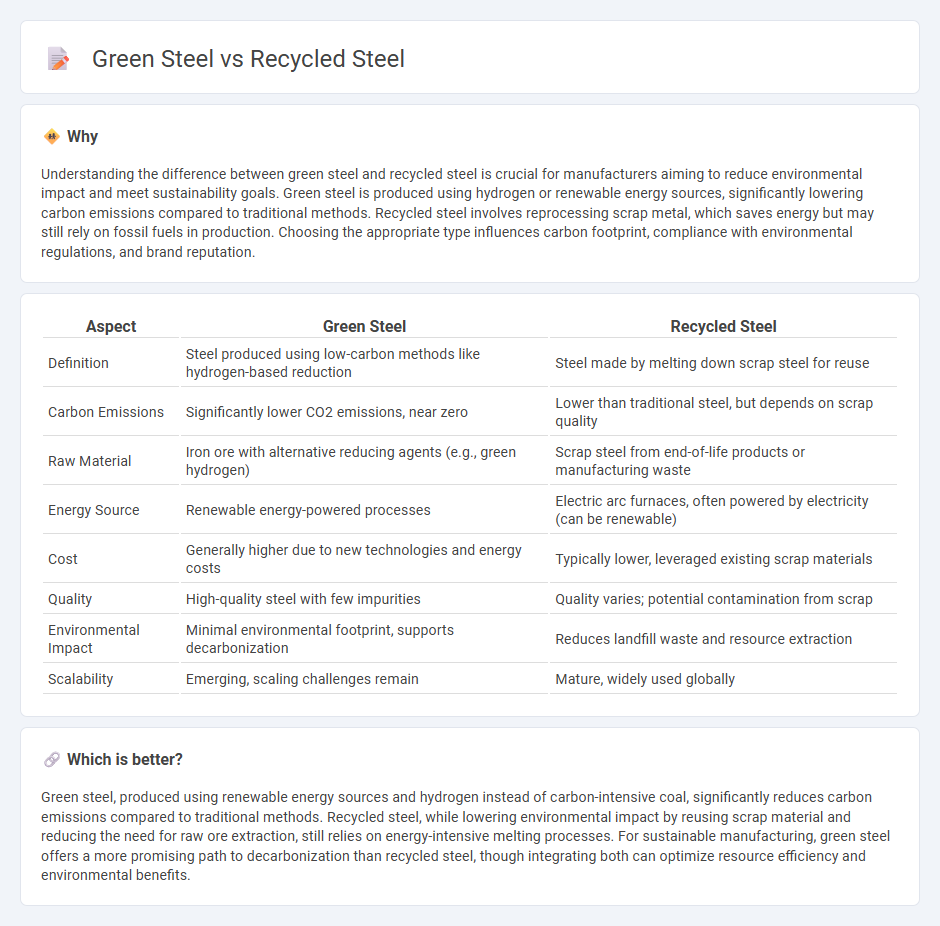

Understanding the difference between green steel and recycled steel is crucial for manufacturers aiming to reduce environmental impact and meet sustainability goals. Green steel is produced using hydrogen or renewable energy sources, significantly lowering carbon emissions compared to traditional methods. Recycled steel involves reprocessing scrap metal, which saves energy but may still rely on fossil fuels in production. Choosing the appropriate type influences carbon footprint, compliance with environmental regulations, and brand reputation.

Comparison Table

| Aspect | Green Steel | Recycled Steel |

|---|---|---|

| Definition | Steel produced using low-carbon methods like hydrogen-based reduction | Steel made by melting down scrap steel for reuse |

| Carbon Emissions | Significantly lower CO2 emissions, near zero | Lower than traditional steel, but depends on scrap quality |

| Raw Material | Iron ore with alternative reducing agents (e.g., green hydrogen) | Scrap steel from end-of-life products or manufacturing waste |

| Energy Source | Renewable energy-powered processes | Electric arc furnaces, often powered by electricity (can be renewable) |

| Cost | Generally higher due to new technologies and energy costs | Typically lower, leveraged existing scrap materials |

| Quality | High-quality steel with few impurities | Quality varies; potential contamination from scrap |

| Environmental Impact | Minimal environmental footprint, supports decarbonization | Reduces landfill waste and resource extraction |

| Scalability | Emerging, scaling challenges remain | Mature, widely used globally |

Which is better?

Green steel, produced using renewable energy sources and hydrogen instead of carbon-intensive coal, significantly reduces carbon emissions compared to traditional methods. Recycled steel, while lowering environmental impact by reusing scrap material and reducing the need for raw ore extraction, still relies on energy-intensive melting processes. For sustainable manufacturing, green steel offers a more promising path to decarbonization than recycled steel, though integrating both can optimize resource efficiency and environmental benefits.

Connection

Green steel production reduces carbon emissions by utilizing hydrogen or renewable energy, while recycled steel minimizes the need for raw ore extraction and energy consumption. The integration of recycled steel in green steel manufacturing enhances sustainability by lowering the overall environmental footprint. Together, they support the manufacturing industry's shift towards eco-friendly practices and reduced greenhouse gas emissions.

Key Terms

Scrap Utilization

Recycled steel primarily leverages scrap metal to reduce the demand for raw iron ore, significantly lowering energy consumption and CO2 emissions compared to traditional steelmaking. Green steel incorporates renewable energy and hydrogen in its production to minimize environmental impact, often combining recycled scrap to enhance sustainability further. Discover more about how scrap utilization is revolutionizing sustainable steel production and driving industry innovation.

Hydrogen Reduction

Recycled steel production relies on melting scrap steel, reducing energy consumption but facing limitations in scrap availability and quality. Green steel using hydrogen reduction replaces carbon-intensive coke with hydrogen, emitting only water vapor and offering a scalable solution for decarbonizing virgin steelmaking. Explore the environmental benefits and technological advancements in hydrogen-based steel production to understand its growing role in sustainable metallurgy.

Carbon Emissions

Recycled steel reduces carbon emissions significantly by requiring 58% less energy compared to producing green steel from raw materials, cutting CO2 output by approximately 70%. Green steel production, although aiming to minimize carbon footprints through hydrogen-based methods, still emits more greenhouse gases during the initial stages compared to recycled steel. Explore further to understand the environmental impacts and innovations driving sustainable steel manufacturing.

Source and External Links

What Is Recycled Steel? - Worthington Steel - Recycled steel is steel reclaimed from used products, construction materials, or manufacturing scrap, melted and reused repeatedly without loss of quality, which conserves natural resources and reduces energy use and emissions compared to producing steel from raw ore.

SUSTAINABILITY IN STEEL RECYCLING - Steel.org - Steel is 100% recyclable into the same quality material repeatedly, is widely recycled due to its magnetic properties, and recycling steel conserves resources, reduces landfill waste, and saves energy with millions of tons recycled annually in North America.

The Benefits of Recycling Steel | GLE Scrap Metal - Recycling steel significantly reduces consumption of iron ore, coal, and water, and lowers CO2 emissions by 58% compared to producing steel from virgin materials, making it environmentally and economically beneficial.

dowidth.com

dowidth.com