Industrial symbiosis optimizes resource use by enabling waste or byproducts from one manufacturing process to serve as inputs for another, creating a collaborative ecosystem that reduces environmental impact. Cradle-to-cradle design focuses on creating products that are fully reusable or recyclable, promoting a circular economy where materials perpetually flow through closed loops. Explore how these sustainable manufacturing models transform production efficiency and environmental responsibility.

Why it is important

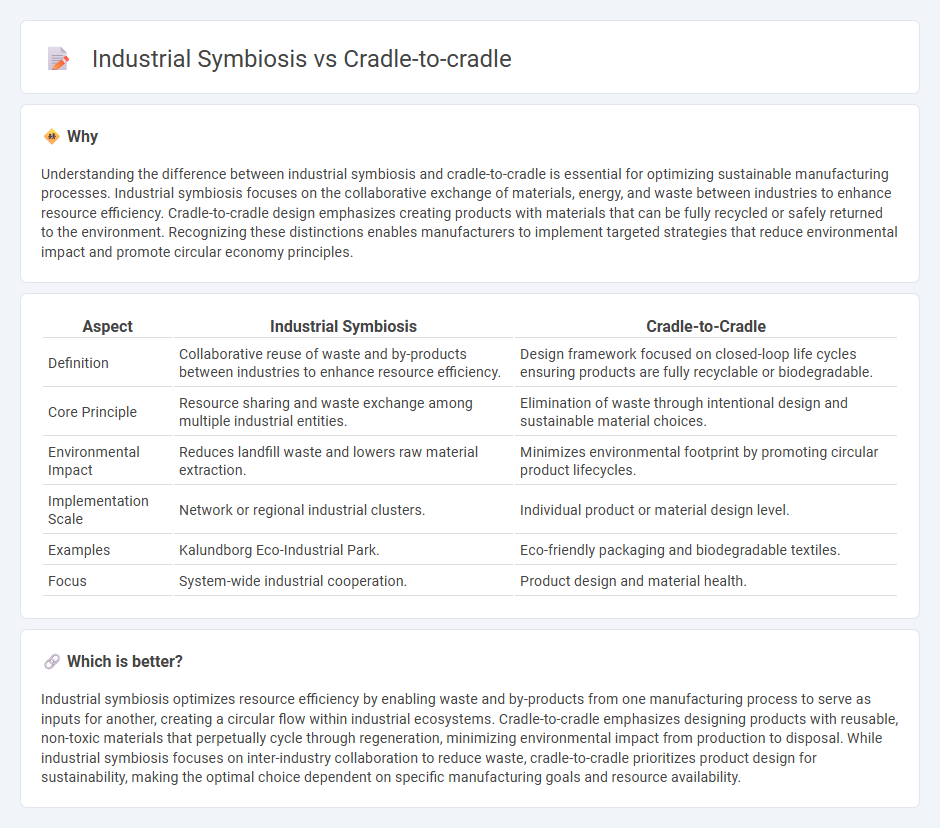

Understanding the difference between industrial symbiosis and cradle-to-cradle is essential for optimizing sustainable manufacturing processes. Industrial symbiosis focuses on the collaborative exchange of materials, energy, and waste between industries to enhance resource efficiency. Cradle-to-cradle design emphasizes creating products with materials that can be fully recycled or safely returned to the environment. Recognizing these distinctions enables manufacturers to implement targeted strategies that reduce environmental impact and promote circular economy principles.

Comparison Table

| Aspect | Industrial Symbiosis | Cradle-to-Cradle |

|---|---|---|

| Definition | Collaborative reuse of waste and by-products between industries to enhance resource efficiency. | Design framework focused on closed-loop life cycles ensuring products are fully recyclable or biodegradable. |

| Core Principle | Resource sharing and waste exchange among multiple industrial entities. | Elimination of waste through intentional design and sustainable material choices. |

| Environmental Impact | Reduces landfill waste and lowers raw material extraction. | Minimizes environmental footprint by promoting circular product lifecycles. |

| Implementation Scale | Network or regional industrial clusters. | Individual product or material design level. |

| Examples | Kalundborg Eco-Industrial Park. | Eco-friendly packaging and biodegradable textiles. |

| Focus | System-wide industrial cooperation. | Product design and material health. |

Which is better?

Industrial symbiosis optimizes resource efficiency by enabling waste and by-products from one manufacturing process to serve as inputs for another, creating a circular flow within industrial ecosystems. Cradle-to-cradle emphasizes designing products with reusable, non-toxic materials that perpetually cycle through regeneration, minimizing environmental impact from production to disposal. While industrial symbiosis focuses on inter-industry collaboration to reduce waste, cradle-to-cradle prioritizes product design for sustainability, making the optimal choice dependent on specific manufacturing goals and resource availability.

Connection

Industrial symbiosis and cradle-to-cradle manufacturing are interconnected through their focus on resource efficiency and waste elimination, where industrial symbiosis enables the exchange of materials, energy, and by-products among different industries to create closed-loop systems. Cradle-to-cradle design promotes the creation of products with materials that can be continuously reused, recycled, or safely composted, aligning perfectly with industrial symbiosis principles by ensuring materials flow within circular industrial ecosystems. Together, these approaches reduce environmental impact, lower production costs, and foster sustainable industrial development.

Key Terms

Circular Economy

Cradle-to-cradle design emphasizes creating products with materials that can be perpetually reused or safely returned to the environment, ensuring zero waste in the Circular Economy. Industrial symbiosis involves the collaborative exchange of waste, energy, or materials between industries to optimize resource efficiency and minimize environmental impact. Explore how these innovative strategies drive sustainable development and enhance resource circularity.

Resource Sharing

Cradle-to-cradle emphasizes designing products for infinite reuse and recycling, promoting closed-loop resource cycles to minimize waste and environmental impact. Industrial symbiosis focuses on resource sharing among different industries by utilizing by-products, energy, or materials from one process as inputs for another, enhancing overall resource efficiency. Explore how these sustainable strategies optimize resource sharing to foster circular economies.

Upcycling

Cradle-to-cradle design emphasizes closed-loop systems where waste materials are repurposed as nutrients, promoting upcycling by converting used products into higher-value materials. Industrial symbiosis involves collaborative networks where waste or by-products of one industry become inputs for another, facilitating resource efficiency and upcycling within industrial ecosystems. Discover more about how these strategies drive sustainable innovation and circular economy practices.

Source and External Links

Cradle-to-cradle design - Wikipedia - Cradle-to-cradle (C2C) design is a biomimetic, sustainable approach that seeks to create products and systems where materials are perpetually reused in either a biological or technical nutrient cycle, eliminating waste by mimicking natural ecosystems.

Cradle to Cradle - Sustainability Guide - C2C treats waste as a resource, designing products so materials remain clean and separable to cycle continuously through biological and technical systems, promoting sustainability and circular economies.

Cradle to Cradle - William McDonough - The C2C framework, created by McDonough and Braungart, is based on three nature-inspired principles: everything is a resource for something else, use of clean renewable energy, and celebrating diversity to create regenerative, waste-free designs.

dowidth.com

dowidth.com