Digital thread integrates data across the entire manufacturing lifecycle, enhancing traceability, quality control, and real-time decision-making. Lean manufacturing focuses on minimizing waste and maximizing efficiency by streamlining processes and improving workflow. Explore how combining digital thread technology with lean principles can revolutionize production management.

Why it is important

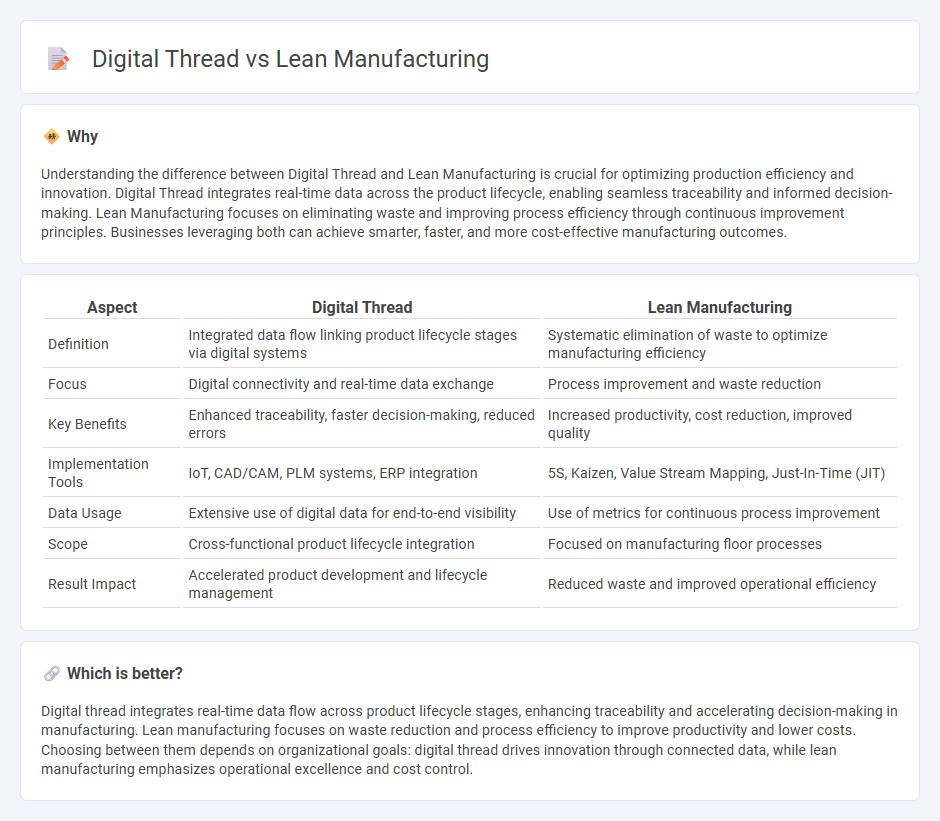

Understanding the difference between Digital Thread and Lean Manufacturing is crucial for optimizing production efficiency and innovation. Digital Thread integrates real-time data across the product lifecycle, enabling seamless traceability and informed decision-making. Lean Manufacturing focuses on eliminating waste and improving process efficiency through continuous improvement principles. Businesses leveraging both can achieve smarter, faster, and more cost-effective manufacturing outcomes.

Comparison Table

| Aspect | Digital Thread | Lean Manufacturing |

|---|---|---|

| Definition | Integrated data flow linking product lifecycle stages via digital systems | Systematic elimination of waste to optimize manufacturing efficiency |

| Focus | Digital connectivity and real-time data exchange | Process improvement and waste reduction |

| Key Benefits | Enhanced traceability, faster decision-making, reduced errors | Increased productivity, cost reduction, improved quality |

| Implementation Tools | IoT, CAD/CAM, PLM systems, ERP integration | 5S, Kaizen, Value Stream Mapping, Just-In-Time (JIT) |

| Data Usage | Extensive use of digital data for end-to-end visibility | Use of metrics for continuous process improvement |

| Scope | Cross-functional product lifecycle integration | Focused on manufacturing floor processes |

| Result Impact | Accelerated product development and lifecycle management | Reduced waste and improved operational efficiency |

Which is better?

Digital thread integrates real-time data flow across product lifecycle stages, enhancing traceability and accelerating decision-making in manufacturing. Lean manufacturing focuses on waste reduction and process efficiency to improve productivity and lower costs. Choosing between them depends on organizational goals: digital thread drives innovation through connected data, while lean manufacturing emphasizes operational excellence and cost control.

Connection

Digital thread enables seamless data integration across the entire manufacturing lifecycle, enhancing Lean manufacturing by providing real-time visibility and analytics that identify waste and inefficiencies. Lean manufacturing principles focus on continuous improvement and value stream optimization, which are supported by the digital thread's capability to link design, production, and quality data for informed decision-making. This synergy accelerates process optimization, reduces lead times, and improves product quality in smart manufacturing environments.

Key Terms

Waste Reduction (Lean manufacturing)

Lean manufacturing emphasizes waste reduction by eliminating non-value-added activities through techniques such as Just-In-Time production, 5S, and Kaizen to enhance process efficiency and reduce inventory costs. The digital thread integrates data across the product lifecycle, enabling real-time visibility and traceability, which supports proactive waste management and continuous improvement initiatives. Explore how combining lean principles with digital thread technology can revolutionize waste reduction in manufacturing.

Value Stream Mapping (Lean manufacturing)

Value Stream Mapping in Lean manufacturing identifies and eliminates waste by visualizing the flow of materials and information through the production process, optimizing efficiency and reducing lead times. The Digital Thread integrates real-time data across the entire product lifecycle, enhancing traceability and collaboration, which complements Value Stream Mapping by providing actionable insights for continuous improvement. Explore how combining Lean methodology with Digital Thread technologies can revolutionize your manufacturing operations.

Data Integration (Digital thread)

Lean manufacturing emphasizes streamlining processes to minimize waste and improve production efficiency, while digital thread focuses on seamless data integration across the entire product lifecycle for enhanced visibility and decision-making. Digital thread connects design, manufacturing, and service data in real time, enabling rapid adjustments and innovation that lean manufacturing's process optimization alone cannot achieve. Explore how combining lean principles with digital thread technologies drives superior operational performance and agility.

Source and External Links

Lean manufacturing - A method focused on reducing production and response times through elimination of non-value-adding activities, based on the Toyota Production System and just-in-time principles, targeting the seven wastes identified by Toyota engineers.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing minimizes waste and maximizes productivity by focusing on customer-valued activities, built on principles like Kaizen and popularized through Toyota's system.

What is Lean Manufacturing and the 5 Principles Used? - TWI - Lean manufacturing maximizes productivity and minimizes waste through five core principles: value, value stream, flow, pull, and perfection, emphasizing efficient workflows and continuous improvement.

dowidth.com

dowidth.com