Additive manufacturing builds objects layer by layer using digital models, offering high precision and material efficiency ideal for complex designs and rapid prototyping. Formative manufacturing shapes materials through molding, casting, or machining, excelling in producing large volumes of identical parts with established cost-effectiveness. Explore the unique advantages and applications of each method to optimize your production strategy.

Why it is important

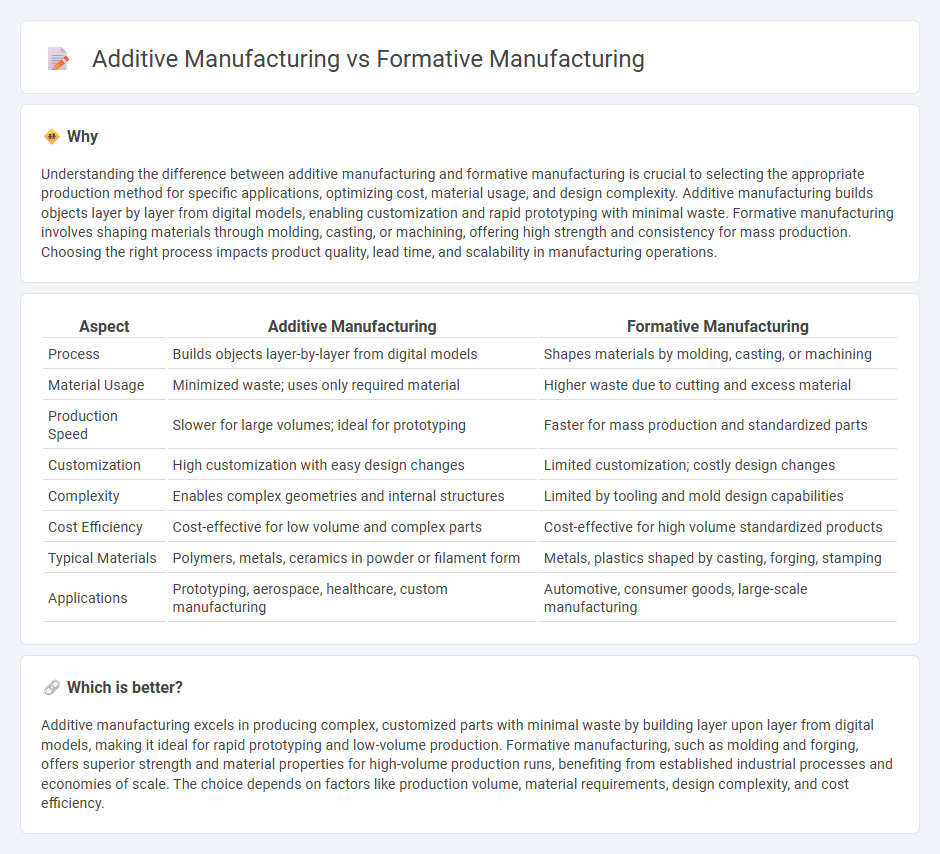

Understanding the difference between additive manufacturing and formative manufacturing is crucial to selecting the appropriate production method for specific applications, optimizing cost, material usage, and design complexity. Additive manufacturing builds objects layer by layer from digital models, enabling customization and rapid prototyping with minimal waste. Formative manufacturing involves shaping materials through molding, casting, or machining, offering high strength and consistency for mass production. Choosing the right process impacts product quality, lead time, and scalability in manufacturing operations.

Comparison Table

| Aspect | Additive Manufacturing | Formative Manufacturing |

|---|---|---|

| Process | Builds objects layer-by-layer from digital models | Shapes materials by molding, casting, or machining |

| Material Usage | Minimized waste; uses only required material | Higher waste due to cutting and excess material |

| Production Speed | Slower for large volumes; ideal for prototyping | Faster for mass production and standardized parts |

| Customization | High customization with easy design changes | Limited customization; costly design changes |

| Complexity | Enables complex geometries and internal structures | Limited by tooling and mold design capabilities |

| Cost Efficiency | Cost-effective for low volume and complex parts | Cost-effective for high volume standardized products |

| Typical Materials | Polymers, metals, ceramics in powder or filament form | Metals, plastics shaped by casting, forging, stamping |

| Applications | Prototyping, aerospace, healthcare, custom manufacturing | Automotive, consumer goods, large-scale manufacturing |

Which is better?

Additive manufacturing excels in producing complex, customized parts with minimal waste by building layer upon layer from digital models, making it ideal for rapid prototyping and low-volume production. Formative manufacturing, such as molding and forging, offers superior strength and material properties for high-volume production runs, benefiting from established industrial processes and economies of scale. The choice depends on factors like production volume, material requirements, design complexity, and cost efficiency.

Connection

Additive manufacturing and formative manufacturing are connected through their complementary roles in producing complex components and optimizing production efficiency. Additive manufacturing builds parts layer-by-layer from digital models, enabling rapid prototyping and customization, while formative manufacturing shapes materials through molding, casting, or forging to achieve high-volume production with consistent mechanical properties. Integrating these methods allows manufacturers to leverage the precision and flexibility of additive processes with the scalability and strength of formative techniques.

Key Terms

Formative Manufacturing:

Formative manufacturing involves shaping materials through processes like casting, forging, or molding, which rely on deforming or reshaping raw materials under heat or pressure to achieve the desired form. This method is highly efficient for mass production of parts with consistent mechanical properties, especially in industries like automotive and aerospace. Explore the advantages and applications of formative manufacturing to understand how it complements or competes with additive manufacturing technologies.

Molding

Formative manufacturing, particularly molding, shapes materials by using molds and applying pressure or heat to achieve desired forms, commonly in injection molding and compression molding processes. Additive manufacturing, or 3D printing, builds objects layer-by-layer from digital models, offering design flexibility and rapid prototyping without molds. Explore how these distinct techniques revolutionize production efficiency and customization in the manufacturing industry.

Casting

Formative manufacturing, particularly casting, involves pouring molten material into molds to create specific shapes, ensuring precise replication and smooth surface finishes, ideal for complex metal components. Additive manufacturing, by contrast, builds objects layer by layer using materials such as plastics or metals, allowing for rapid prototyping and intricate geometries without the need for molds. Explore detailed comparisons and benefits of casting versus additive manufacturing for your production needs.

Source and External Links

New HyFAM Method Combines Additive and Formative Manufacturing - Formative manufacturing refers to processes like molding and casting that produce high-quality parts quickly by shaping material in molds, often with complex tooling, distinct from additive manufacturing; a new hybrid method called HyFAM merges formative speed and quality with additive precision for improved production efficiency.

Infographic: Formative Manufacturing Technologies Selection Guide - Formative manufacturing encompasses technologies such as injection molding, urethane casting, plastic extrusion, thermoforming, compression molding, blow molding, and die casting, all characterized by creating parts through shaping material in molds or dies, offering precision, scalability, and efficiency for various applications.

3 Types of Manufacturing - Additive, Subtractive, and Forming - Formative manufacturing involves making parts by filling molds with liquid or molten material (like injection molding) to produce high volumes of identical items efficiently, though tooling creation can be costly and time-consuming compared to other manufacturing types.

dowidth.com

dowidth.com