Microfactories enable localized, small-scale production with flexible and rapid manufacturing processes, reducing lead times and transportation costs. Distributed manufacturing leverages a network of decentralized production sites to optimize resource use and enhance supply chain resilience. Explore how these innovative approaches are transforming global manufacturing strategies.

Why it is important

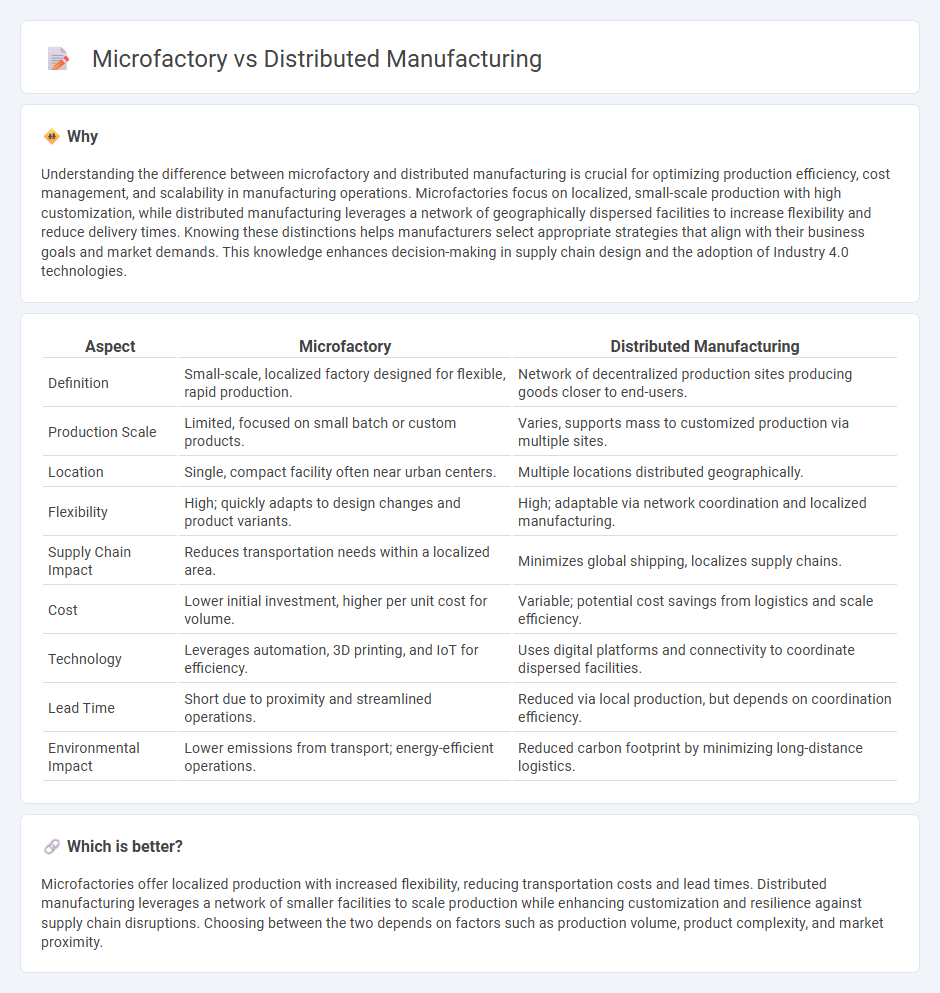

Understanding the difference between microfactory and distributed manufacturing is crucial for optimizing production efficiency, cost management, and scalability in manufacturing operations. Microfactories focus on localized, small-scale production with high customization, while distributed manufacturing leverages a network of geographically dispersed facilities to increase flexibility and reduce delivery times. Knowing these distinctions helps manufacturers select appropriate strategies that align with their business goals and market demands. This knowledge enhances decision-making in supply chain design and the adoption of Industry 4.0 technologies.

Comparison Table

| Aspect | Microfactory | Distributed Manufacturing |

|---|---|---|

| Definition | Small-scale, localized factory designed for flexible, rapid production. | Network of decentralized production sites producing goods closer to end-users. |

| Production Scale | Limited, focused on small batch or custom products. | Varies, supports mass to customized production via multiple sites. |

| Location | Single, compact facility often near urban centers. | Multiple locations distributed geographically. |

| Flexibility | High; quickly adapts to design changes and product variants. | High; adaptable via network coordination and localized manufacturing. |

| Supply Chain Impact | Reduces transportation needs within a localized area. | Minimizes global shipping, localizes supply chains. |

| Cost | Lower initial investment, higher per unit cost for volume. | Variable; potential cost savings from logistics and scale efficiency. |

| Technology | Leverages automation, 3D printing, and IoT for efficiency. | Uses digital platforms and connectivity to coordinate dispersed facilities. |

| Lead Time | Short due to proximity and streamlined operations. | Reduced via local production, but depends on coordination efficiency. |

| Environmental Impact | Lower emissions from transport; energy-efficient operations. | Reduced carbon footprint by minimizing long-distance logistics. |

Which is better?

Microfactories offer localized production with increased flexibility, reducing transportation costs and lead times. Distributed manufacturing leverages a network of smaller facilities to scale production while enhancing customization and resilience against supply chain disruptions. Choosing between the two depends on factors such as production volume, product complexity, and market proximity.

Connection

Microfactories and distributed manufacturing are interconnected by enabling localized, small-scale production units that reduce supply chain complexity and increase responsiveness to market demands. Microfactories utilize advanced technologies such as automation and IoT to produce customized products closer to the end consumer, which aligns with the principles of distributed manufacturing. This synergy enhances flexibility, reduces transportation costs, and supports sustainable manufacturing practices across various industries.

Key Terms

Decentralization

Distributed manufacturing decentralizes production by spreading processes across multiple geographically dispersed facilities, enhancing flexibility and reducing transportation costs. Microfactories further this decentralization by utilizing compact, modular units localized near demand centers, enabling rapid customization and scalability. Explore the advantages and use cases of decentralized manufacturing models to optimize your production strategy.

Scale

Distributed manufacturing enables large-scale production by leveraging multiple, geographically dispersed facilities to reduce shipping costs and improve responsiveness. Microfactories focus on small-scale, localized production, emphasizing flexibility and customization while minimizing overhead. Explore the benefits and trade-offs of both models to determine the ideal scale for your manufacturing needs.

Customization

Distributed manufacturing leverages multiple decentralized production locations to tailor products closely to local consumer preferences, enabling flexible customization at scale. Microfactories operate as small-scale, highly automated units specializing in producing custom, small-batch goods with rapid turnaround times. Explore the advantages of customization through distributed manufacturing and microfactory models to optimize your production strategy.

Source and External Links

Distributed manufacturing benefits: Revolutionizing production - Distributed manufacturing involves a network of smaller, geographically dispersed facilities enabled by digital technologies, allowing for localized production closer to consumers, reducing shipping costs, and increasing flexibility and customization.

Distributed Manufacturing: The Way of the Future? - This model spreads production across multiple local sites, using methods like modular, on-demand, and recycling-based manufacturing to produce goods near where they are used, improving supply chain sustainability and responsiveness.

What Is Distributed Manufacturing? - MRPeasy Blog - Defined as a business model with production spread over many facilities, distributed manufacturing focuses on local production for regional markets with centralized digital management, balancing higher production costs with shorter lead times and lower distribution expenses.

dowidth.com

dowidth.com