Additive manufacturing builds objects layer by layer from digital models, offering design flexibility and material efficiency ideal for prototypes and complex geometries. CNC milling removes material from solid blocks with precision cutting tools, delivering high accuracy and surface finish for durable parts in industries like aerospace and automotive. Explore the strengths and applications of additive manufacturing versus CNC milling to optimize your production processes.

Why it is important

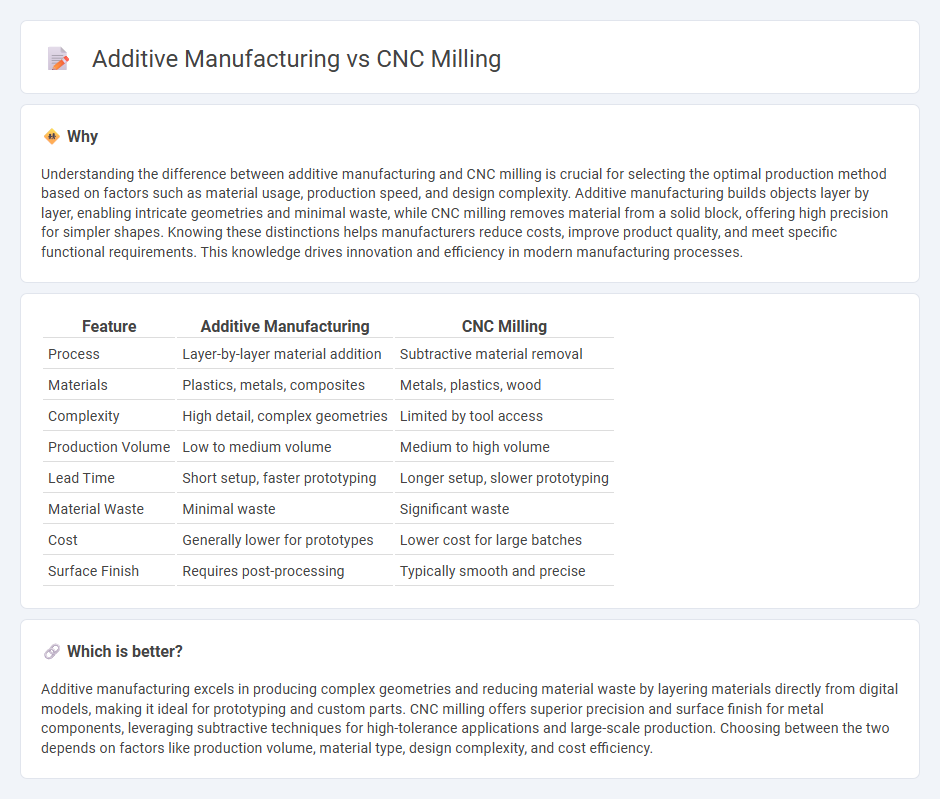

Understanding the difference between additive manufacturing and CNC milling is crucial for selecting the optimal production method based on factors such as material usage, production speed, and design complexity. Additive manufacturing builds objects layer by layer, enabling intricate geometries and minimal waste, while CNC milling removes material from a solid block, offering high precision for simpler shapes. Knowing these distinctions helps manufacturers reduce costs, improve product quality, and meet specific functional requirements. This knowledge drives innovation and efficiency in modern manufacturing processes.

Comparison Table

| Feature | Additive Manufacturing | CNC Milling |

|---|---|---|

| Process | Layer-by-layer material addition | Subtractive material removal |

| Materials | Plastics, metals, composites | Metals, plastics, wood |

| Complexity | High detail, complex geometries | Limited by tool access |

| Production Volume | Low to medium volume | Medium to high volume |

| Lead Time | Short setup, faster prototyping | Longer setup, slower prototyping |

| Material Waste | Minimal waste | Significant waste |

| Cost | Generally lower for prototypes | Lower cost for large batches |

| Surface Finish | Requires post-processing | Typically smooth and precise |

Which is better?

Additive manufacturing excels in producing complex geometries and reducing material waste by layering materials directly from digital models, making it ideal for prototyping and custom parts. CNC milling offers superior precision and surface finish for metal components, leveraging subtractive techniques for high-tolerance applications and large-scale production. Choosing between the two depends on factors like production volume, material type, design complexity, and cost efficiency.

Connection

Additive manufacturing and CNC milling are interconnected through their complementary roles in modern manufacturing workflows, where additive processes build complex geometries layer by layer and CNC milling refines these parts by precisely removing excess material. Integrating both techniques enhances production efficiency, material utilization, and design flexibility in industries like aerospace and automotive. Advanced software now enables seamless transition between additive modeling and CNC machining paths, optimizing overall manufacturing quality and speed.

Key Terms

Subtractive machining

CNC milling utilizes subtractive machining by precisely removing material from a solid block to create complex parts with tight tolerances and superior surface finishes. This method excels in producing metal components for aerospace, automotive, and medical industries due to its accuracy and repeatability. Explore the advantages and applications of subtractive machining compared to additive manufacturing to optimize your production process.

Layer-by-layer deposition

CNC milling removes material from a solid block through precise cutting tools, ensuring high accuracy and surface finish, while additive manufacturing builds parts layer-by-layer by depositing material, enabling complex geometries and reduced waste. Additive processes such as selective laser sintering or fused deposition modeling allow for customization and rapid prototyping that conventional subtractive methods struggle to achieve. Discover the detailed advantages and applications of each technique by exploring their layer-by-layer deposition characteristics.

Toolpath generation

CNC milling relies on precise toolpath generation to control cutting movements for subtractive manufacturing, using G-code programming to optimize material removal and surface finish. Additive manufacturing toolpaths, generated through slicing software, control layer-by-layer material deposition, focusing on optimizing build orientation, support structures, and printing speed. Explore detailed comparisons of toolpath generation techniques to enhance manufacturing efficiency and product quality.

Source and External Links

What is CNC milling? | Protolabs Network - CNC milling is a machining process using computer numerical control systems combined with multi-point cutting tools to remove material from a solid block to create precise parts from materials like metal, plastic, or wood, following a CAD design converted into G-code instructions.

CNC Milling Explained: A Comprehensive Guide to Precision Manufacturing - CNC milling uses rotary cutters controlled by pre-programmed software to remove material and create complex features such as slots, holes, and 3D contours on a workpiece, with steps including CAD design, CAM programming, machine setup, and finishing.

Custom CNC Milling Services - Xometry - CNC milling involves an automated rotating spindle that cuts harder materials by following G-code commands created by CAM software, enabling precise machining usually in industrial settings where both the tool head and workpiece can move for detailed profile cutting.

dowidth.com

dowidth.com