Machine vision inspection uses cameras and image processing algorithms to detect defects, measure dimensions, and ensure product quality with high speed and precision. Capacitive measurement relies on changes in electrical capacitance to determine material properties or position, offering non-contact sensing ideal for detecting thickness or dielectric variations. Discover how these advanced techniques transform manufacturing processes and improve quality control.

Why it is important

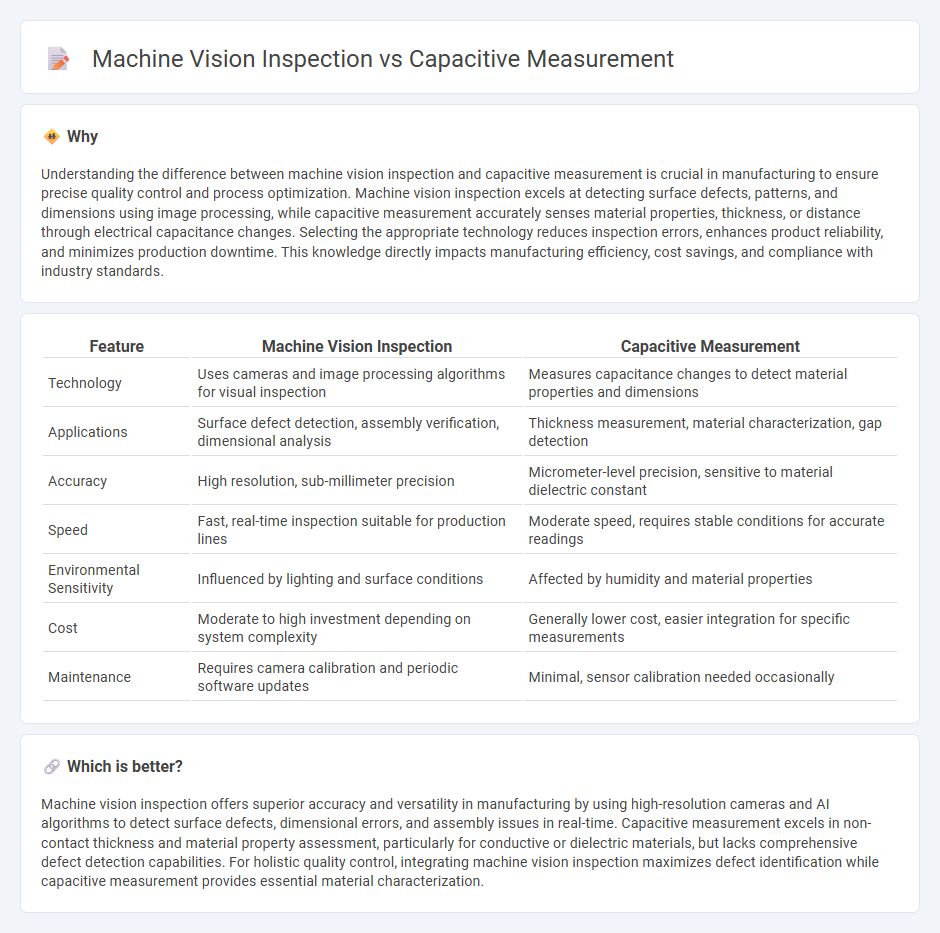

Understanding the difference between machine vision inspection and capacitive measurement is crucial in manufacturing to ensure precise quality control and process optimization. Machine vision inspection excels at detecting surface defects, patterns, and dimensions using image processing, while capacitive measurement accurately senses material properties, thickness, or distance through electrical capacitance changes. Selecting the appropriate technology reduces inspection errors, enhances product reliability, and minimizes production downtime. This knowledge directly impacts manufacturing efficiency, cost savings, and compliance with industry standards.

Comparison Table

| Feature | Machine Vision Inspection | Capacitive Measurement |

|---|---|---|

| Technology | Uses cameras and image processing algorithms for visual inspection | Measures capacitance changes to detect material properties and dimensions |

| Applications | Surface defect detection, assembly verification, dimensional analysis | Thickness measurement, material characterization, gap detection |

| Accuracy | High resolution, sub-millimeter precision | Micrometer-level precision, sensitive to material dielectric constant |

| Speed | Fast, real-time inspection suitable for production lines | Moderate speed, requires stable conditions for accurate readings |

| Environmental Sensitivity | Influenced by lighting and surface conditions | Affected by humidity and material properties |

| Cost | Moderate to high investment depending on system complexity | Generally lower cost, easier integration for specific measurements |

| Maintenance | Requires camera calibration and periodic software updates | Minimal, sensor calibration needed occasionally |

Which is better?

Machine vision inspection offers superior accuracy and versatility in manufacturing by using high-resolution cameras and AI algorithms to detect surface defects, dimensional errors, and assembly issues in real-time. Capacitive measurement excels in non-contact thickness and material property assessment, particularly for conductive or dielectric materials, but lacks comprehensive defect detection capabilities. For holistic quality control, integrating machine vision inspection maximizes defect identification while capacitive measurement provides essential material characterization.

Connection

Machine vision inspection and capacitive measurement are interconnected in manufacturing through their complementary roles in quality control and precision monitoring. Machine vision systems utilize cameras and image processing algorithms to detect surface defects and dimensional inaccuracies, while capacitive measurement provides highly accurate distance or thickness data based on changes in electrical capacitance. Integrating these technologies enhances defect detection accuracy and ensures consistent product specifications by combining visual inspection with precise, non-contact measurements.

Key Terms

Dielectric Properties

Capacitive measurement techniques directly evaluate dielectric properties by detecting changes in capacitance caused by material permittivity variations, offering precise insights into insulating layers and substrate conditions. Machine vision inspection relies on optical data to analyze surface characteristics and defects but lacks the ability to measure underlying dielectric constants or material composition. Explore more to understand the detailed applications and advantages of both methods in industrial quality control.

Optical Imaging

Optical imaging in machine vision inspection leverages high-resolution cameras and sophisticated algorithms to detect surface defects, color variations, and dimensional accuracy in real-time. Capacitive measurement, by contrast, relies on changes in electrical properties to assess material thickness or presence, but lacks detailed visual context for complex inspections. Explore more to understand how optical imaging revolutionizes precision and defect detection in automated quality control.

Non-contact Sensing

Capacitive measurement leverages changes in electrical capacitance to detect object presence and properties without physical contact, excelling in identifying material thickness, humidity, and surface characteristics. Machine vision inspection uses cameras and advanced image processing algorithms to capture detailed visual data for quality control and defect detection in manufacturing. Explore the latest advancements in non-contact sensing technologies to enhance precision and efficiency in industrial applications.

Source and External Links

Capacitive Displacement Sensors: Working Principle & Applications - Capacitive sensors measure displacement or thickness by detecting changes in an electric field, offering high resolution, non-contact operation, and stability across various materials and environmental conditions.

Capacitive sensing - Wikipedia - Capacitive sensing detects and measures conductive objects or materials with a different dielectric constant than air, widely used in touchscreens, proximity sensors, and various industrial applications.

Capacitive Sensors - PI-USA - These sensors use two conductive plates and a high-frequency alternating current to measure position or displacement with nanometer accuracy, ideal for precision nanopositioning systems.

dowidth.com

dowidth.com