Industrial Internet integrates smart sensors and real-time data analytics to enhance manufacturing processes, enabling predictive maintenance and optimized operations. Cloud Manufacturing leverages scalable cloud computing resources to facilitate flexible production management and seamless collaboration across global networks. Explore deeper to understand how these technologies revolutionize modern manufacturing.

Why it is important

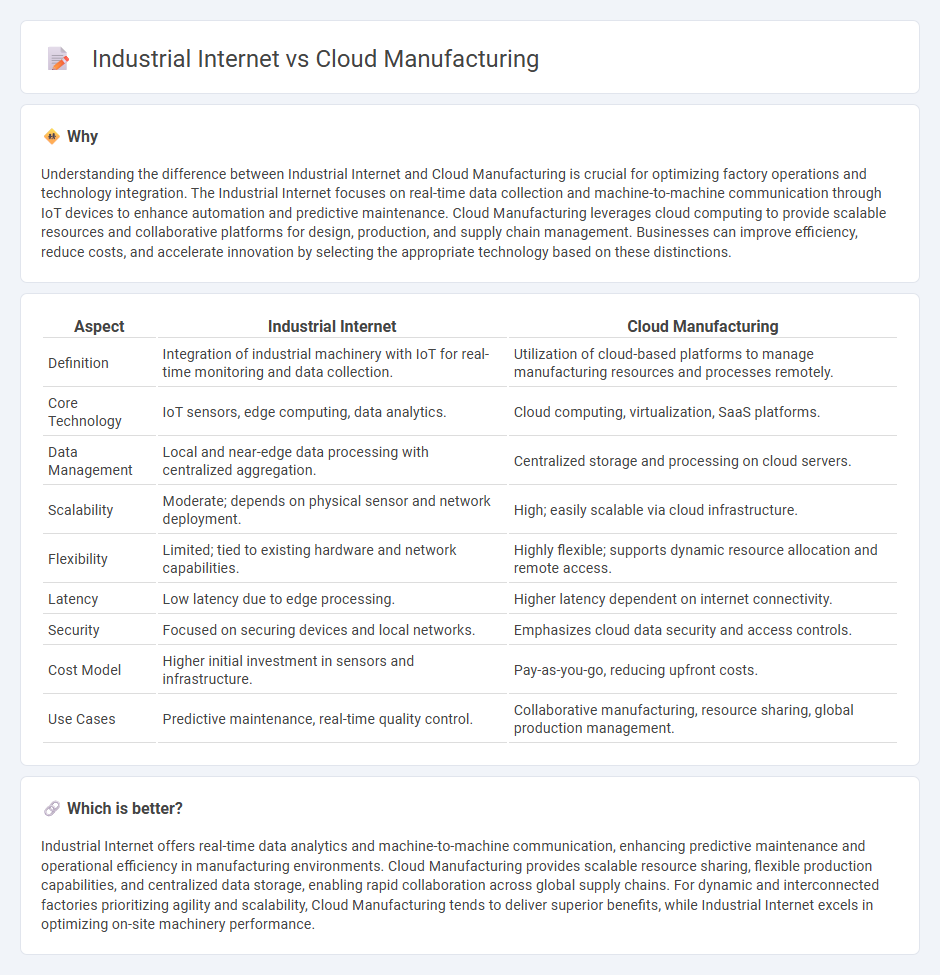

Understanding the difference between Industrial Internet and Cloud Manufacturing is crucial for optimizing factory operations and technology integration. The Industrial Internet focuses on real-time data collection and machine-to-machine communication through IoT devices to enhance automation and predictive maintenance. Cloud Manufacturing leverages cloud computing to provide scalable resources and collaborative platforms for design, production, and supply chain management. Businesses can improve efficiency, reduce costs, and accelerate innovation by selecting the appropriate technology based on these distinctions.

Comparison Table

| Aspect | Industrial Internet | Cloud Manufacturing |

|---|---|---|

| Definition | Integration of industrial machinery with IoT for real-time monitoring and data collection. | Utilization of cloud-based platforms to manage manufacturing resources and processes remotely. |

| Core Technology | IoT sensors, edge computing, data analytics. | Cloud computing, virtualization, SaaS platforms. |

| Data Management | Local and near-edge data processing with centralized aggregation. | Centralized storage and processing on cloud servers. |

| Scalability | Moderate; depends on physical sensor and network deployment. | High; easily scalable via cloud infrastructure. |

| Flexibility | Limited; tied to existing hardware and network capabilities. | Highly flexible; supports dynamic resource allocation and remote access. |

| Latency | Low latency due to edge processing. | Higher latency dependent on internet connectivity. |

| Security | Focused on securing devices and local networks. | Emphasizes cloud data security and access controls. |

| Cost Model | Higher initial investment in sensors and infrastructure. | Pay-as-you-go, reducing upfront costs. |

| Use Cases | Predictive maintenance, real-time quality control. | Collaborative manufacturing, resource sharing, global production management. |

Which is better?

Industrial Internet offers real-time data analytics and machine-to-machine communication, enhancing predictive maintenance and operational efficiency in manufacturing environments. Cloud Manufacturing provides scalable resource sharing, flexible production capabilities, and centralized data storage, enabling rapid collaboration across global supply chains. For dynamic and interconnected factories prioritizing agility and scalability, Cloud Manufacturing tends to deliver superior benefits, while Industrial Internet excels in optimizing on-site machinery performance.

Connection

The Industrial Internet integrates smart sensors, machines, and data analytics to optimize manufacturing processes, driving efficiency and predictive maintenance. Cloud Manufacturing leverages this connectivity by providing scalable, on-demand computing resources and data storage, enabling real-time collaboration and remote monitoring. Together, they enhance production agility, reduce downtime, and facilitate intelligent decision-making in modern manufacturing environments.

Key Terms

Resource Virtualization

Cloud manufacturing leverages resource virtualization by transforming physical manufacturing assets into virtual resources accessible via the internet, enhancing flexibility and scalability in production processes. The industrial internet emphasizes interconnected devices and real-time data collection to optimize asset performance and maintenance, but resource virtualization is less central compared to cloud manufacturing. Explore how resource virtualization drives innovation in cloud manufacturing versus the industrial internet to understand their distinct impacts.

Cyber-Physical Systems

Cloud Manufacturing integrates cyber-physical systems (CPS) by utilizing cloud computing to enable real-time data sharing, resource pooling, and flexible production processes, enhancing manufacturing efficiency and scalability. The Industrial Internet, centered on CPS, emphasizes connectivity and data analytics across industrial devices, improving predictive maintenance, automation, and operational intelligence. Discover how these technologies transform smart manufacturing ecosystems and drive the future of industrial innovation.

Data Interoperability

Cloud manufacturing leverages distributed computing and virtualization to enable real-time resource sharing and process coordination across enterprise networks, while the Industrial Internet emphasizes seamless connectivity and data exchange among heterogeneous industrial devices and systems. Data interoperability in cloud manufacturing is achieved through standardized protocols like MTConnect and OPC UA, ensuring uniform data representation and integration across manufacturing processes. Explore deeper insights into how these paradigms enhance operational efficiency through optimized data interoperability frameworks.

Source and External Links

Cloud manufacturing - Wikipedia - Cloud manufacturing (CMfg) is a new manufacturing paradigm combining cloud computing, IoT, virtualization, and service-oriented technologies to convert manufacturing resources and capabilities into on-demand services across a product's lifecycle, enabling intelligent, unified management and full resource sharing.

What is Cloud Manufacturing & How Does It Work? - Cloud manufacturing is a business strategy using cloud computing systems to manage manufacturing operations remotely, enhancing workflow speed, productivity, and cost-efficiency while enabling global access and integration of manufacturing processes.

What is Microsoft Cloud for Manufacturing? - Microsoft Cloud for Manufacturing offers integrated cloud and AI-powered solutions to accelerate digital transformation in manufacturing, supporting innovation, supply chain resilience, intelligent factories, and enhanced customer experiences through connected industry solutions.

dowidth.com

dowidth.com