Collaborative robots (cobots) enhance manufacturing efficiency by working safely alongside human operators, enabling flexible automation for complex tasks. Machine vision systems provide precise inspection and quality control through advanced image processing, reducing defects and improving production accuracy. Explore how integrating cobots and machine vision can transform your manufacturing processes.

Why it is important

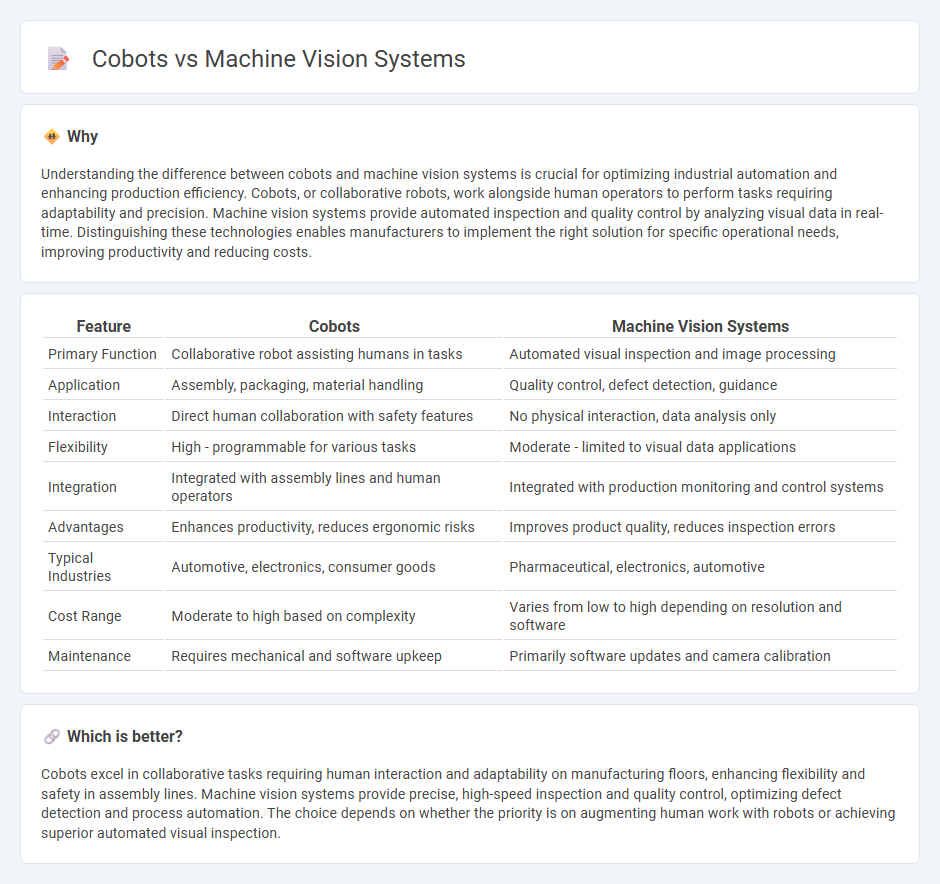

Understanding the difference between cobots and machine vision systems is crucial for optimizing industrial automation and enhancing production efficiency. Cobots, or collaborative robots, work alongside human operators to perform tasks requiring adaptability and precision. Machine vision systems provide automated inspection and quality control by analyzing visual data in real-time. Distinguishing these technologies enables manufacturers to implement the right solution for specific operational needs, improving productivity and reducing costs.

Comparison Table

| Feature | Cobots | Machine Vision Systems |

|---|---|---|

| Primary Function | Collaborative robot assisting humans in tasks | Automated visual inspection and image processing |

| Application | Assembly, packaging, material handling | Quality control, defect detection, guidance |

| Interaction | Direct human collaboration with safety features | No physical interaction, data analysis only |

| Flexibility | High - programmable for various tasks | Moderate - limited to visual data applications |

| Integration | Integrated with assembly lines and human operators | Integrated with production monitoring and control systems |

| Advantages | Enhances productivity, reduces ergonomic risks | Improves product quality, reduces inspection errors |

| Typical Industries | Automotive, electronics, consumer goods | Pharmaceutical, electronics, automotive |

| Cost Range | Moderate to high based on complexity | Varies from low to high depending on resolution and software |

| Maintenance | Requires mechanical and software upkeep | Primarily software updates and camera calibration |

Which is better?

Cobots excel in collaborative tasks requiring human interaction and adaptability on manufacturing floors, enhancing flexibility and safety in assembly lines. Machine vision systems provide precise, high-speed inspection and quality control, optimizing defect detection and process automation. The choice depends on whether the priority is on augmenting human work with robots or achieving superior automated visual inspection.

Connection

Cobots integrate with machine vision systems to enhance precision and efficiency in manufacturing by enabling real-time object recognition, quality inspection, and adaptive task execution. Machine vision provides cobots with critical visual data that allows for accurate part identification, defect detection, and spatial awareness, optimizing automation workflows. This synergy improves assembly line productivity and reduces errors by facilitating seamless human-robot collaboration and dynamic environment interaction.

Key Terms

Image Processing

Machine vision systems excel in high-speed image processing with advanced algorithms for defect detection and quality control in manufacturing, offering precise, real-time analysis of visual data. Cobots integrate image processing capabilities primarily for safe human-robot interaction and spatial awareness, enabling adaptive responses without compromising efficiency. Explore the latest advancements in image processing technology to understand how both solutions optimize industrial automation.

Collaborative Safety

Machine vision systems enhance collaborative safety by continuously monitoring workplaces, detecting hazards, and ensuring robots operate within safe zones to prevent human injury. Cobots incorporate built-in sensors and compliant control systems to dynamically adjust their movements during interactions, minimizing collision risks. Explore in-depth how integrating advanced safety features in machine vision and cobot technologies transforms industrial collaboration.

Automated Inspection

Machine vision systems excel in automated inspection by providing precise image analysis and defect detection at high speeds, ensuring consistent quality control in manufacturing processes. Cobots, equipped with vision capabilities, offer flexibility to adapt inspection tasks while collaborating safely with human operators in dynamic environments. Explore the latest advancements to enhance your automated inspection solutions with machine vision and cobots.

Source and External Links

Machine Vision | KEYENCE America - Machine vision systems use high-speed cameras, sensors, and AI-driven software to perform tasks like inspection, object recognition, and autonomous navigation in manufacturing processes.

Machine Vision Manufacturers | Machine Vision Systems - These systems combine vision sensors, lighting, cameras, processors, and specialized software to enable precise tasks such as defect detection, sorting, and robotic guidance in industrial environments.

Machine vision - Wikipedia - Machine vision refers to imaging-based automatic inspection and analysis technologies that use cameras, lighting, and software to extract information and make decisions, primarily for quality control and sorting in industrial applications.

dowidth.com

dowidth.com