Microfactories enable localized, flexible production with reduced lead times and minimal space requirements, ideal for custom or small-batch manufacturing. Modular manufacturing uses standardized, interchangeable modules to streamline assembly processes, enhancing scalability and efficiency in larger production environments. Explore the distinct advantages and applications of microfactories and modular manufacturing to optimize your production strategy.

Why it is important

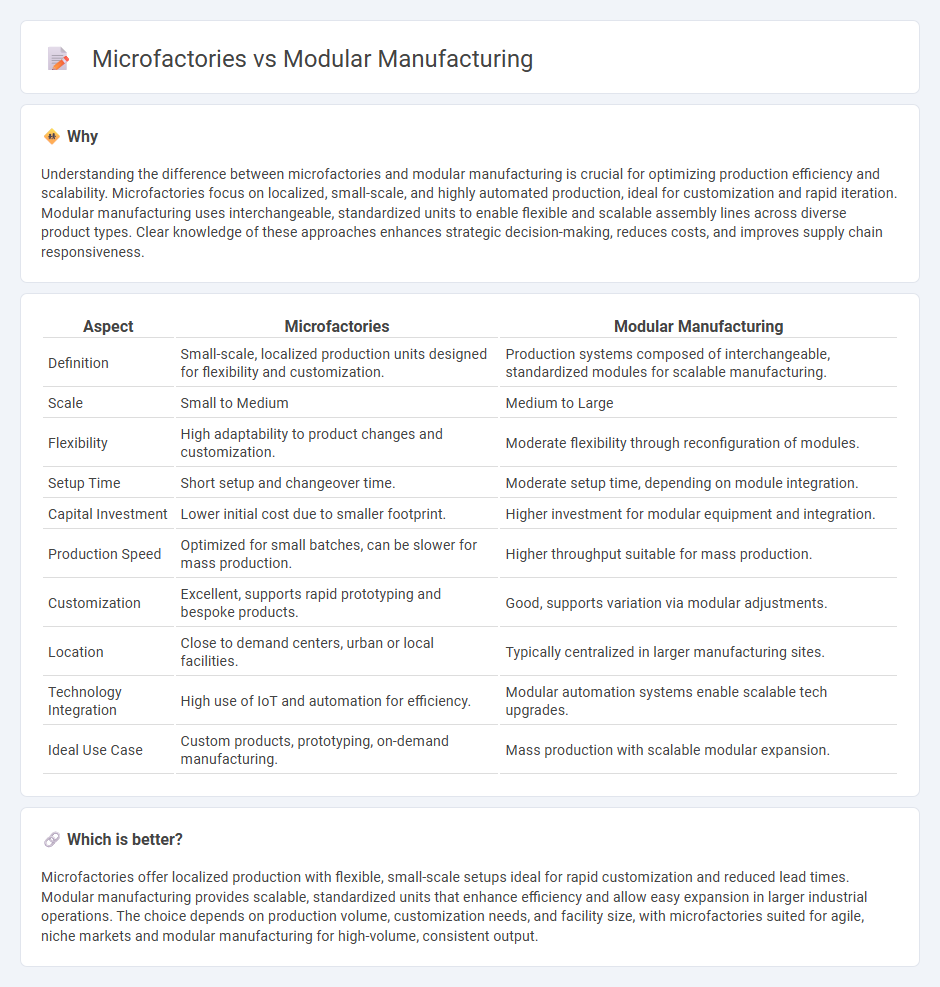

Understanding the difference between microfactories and modular manufacturing is crucial for optimizing production efficiency and scalability. Microfactories focus on localized, small-scale, and highly automated production, ideal for customization and rapid iteration. Modular manufacturing uses interchangeable, standardized units to enable flexible and scalable assembly lines across diverse product types. Clear knowledge of these approaches enhances strategic decision-making, reduces costs, and improves supply chain responsiveness.

Comparison Table

| Aspect | Microfactories | Modular Manufacturing |

|---|---|---|

| Definition | Small-scale, localized production units designed for flexibility and customization. | Production systems composed of interchangeable, standardized modules for scalable manufacturing. |

| Scale | Small to Medium | Medium to Large |

| Flexibility | High adaptability to product changes and customization. | Moderate flexibility through reconfiguration of modules. |

| Setup Time | Short setup and changeover time. | Moderate setup time, depending on module integration. |

| Capital Investment | Lower initial cost due to smaller footprint. | Higher investment for modular equipment and integration. |

| Production Speed | Optimized for small batches, can be slower for mass production. | Higher throughput suitable for mass production. |

| Customization | Excellent, supports rapid prototyping and bespoke products. | Good, supports variation via modular adjustments. |

| Location | Close to demand centers, urban or local facilities. | Typically centralized in larger manufacturing sites. |

| Technology Integration | High use of IoT and automation for efficiency. | Modular automation systems enable scalable tech upgrades. |

| Ideal Use Case | Custom products, prototyping, on-demand manufacturing. | Mass production with scalable modular expansion. |

Which is better?

Microfactories offer localized production with flexible, small-scale setups ideal for rapid customization and reduced lead times. Modular manufacturing provides scalable, standardized units that enhance efficiency and allow easy expansion in larger industrial operations. The choice depends on production volume, customization needs, and facility size, with microfactories suited for agile, niche markets and modular manufacturing for high-volume, consistent output.

Connection

Microfactories utilize modular manufacturing principles by integrating scalable, prefabricated units to enable flexible, efficient production within compact spaces. This approach allows rapid reconfiguration of manufacturing lines to respond to market demands and reduces setup time and costs. Modular manufacturing in microfactories enhances customization capabilities while optimizing resource utilization and minimizing waste.

Key Terms

Production scalability

Modular manufacturing enables scalable production through standardized, interchangeable units that streamline assembly processes, reducing downtime and boosting output flexibility. Microfactories specialize in compact, localized production with advanced automation, allowing rapid adaptation to market demand and minimizing logistical costs. Explore the benefits and applications of these innovative production models to optimize your manufacturing strategy.

Flexibility

Modular manufacturing enhances production adaptability by allowing quick reconfiguration of standardized units, leading to reduced downtime and efficient scaling. Microfactories emphasize localized, compact setups that enable rapid customization and responsiveness to market demands, maximizing operational flexibility. Explore the distinct advantages of modular manufacturing and microfactories to understand how flexibility can transform your production strategy.

Decentralization

Modular manufacturing enables decentralized production by breaking down complex products into standardized, interchangeable units that can be manufactured independently across multiple locations. Microfactories further decentralize manufacturing processes by operating small-scale, highly flexible facilities situated close to end markets, reducing transportation costs and lead times. Explore the benefits and differences of these decentralization strategies to optimize your production network.

Source and External Links

The Benefits of Modular Design in Manufacturing - Modular manufacturing produces standardized, interchangeable modules that are assembled into final products, enhancing efficiency, flexibility, and cost savings across industries like automotive, electronics, construction, and aerospace.

Modular Manufacturing - This manufacturing strategy uses standardized, compatible modules produced at different sites, allowing streamlined production, easier upgrades, and faster responses to market changes, while reducing waste and improving supply chain flexibility.

Modular manufacturing systems - Modular manufacturing systems aim to increase operational flexibility by enabling scalable, easily reconfigurable production equipment that can adapt quickly to changing manufacturing needs and move locations if required.

dowidth.com

dowidth.com