Digital twinning creates a virtual replica of physical manufacturing assets, enabling real-time simulation and predictive analytics to optimize production processes. Manufacturing Execution Systems (MES) focus on managing and monitoring real-time factory floor operations, ensuring precise control over workflows, quality, and compliance. Explore how integrating digital twinning with MES can revolutionize manufacturing efficiency and innovation.

Why it is important

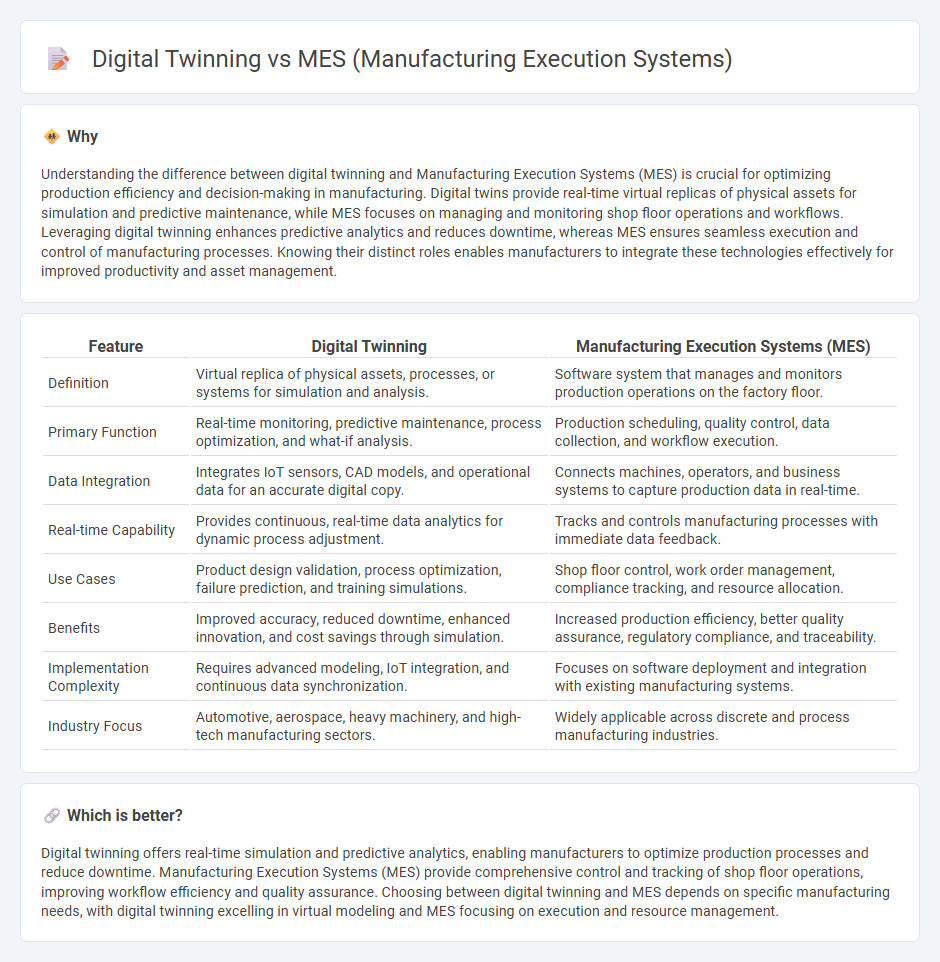

Understanding the difference between digital twinning and Manufacturing Execution Systems (MES) is crucial for optimizing production efficiency and decision-making in manufacturing. Digital twins provide real-time virtual replicas of physical assets for simulation and predictive maintenance, while MES focuses on managing and monitoring shop floor operations and workflows. Leveraging digital twinning enhances predictive analytics and reduces downtime, whereas MES ensures seamless execution and control of manufacturing processes. Knowing their distinct roles enables manufacturers to integrate these technologies effectively for improved productivity and asset management.

Comparison Table

| Feature | Digital Twinning | Manufacturing Execution Systems (MES) |

|---|---|---|

| Definition | Virtual replica of physical assets, processes, or systems for simulation and analysis. | Software system that manages and monitors production operations on the factory floor. |

| Primary Function | Real-time monitoring, predictive maintenance, process optimization, and what-if analysis. | Production scheduling, quality control, data collection, and workflow execution. |

| Data Integration | Integrates IoT sensors, CAD models, and operational data for an accurate digital copy. | Connects machines, operators, and business systems to capture production data in real-time. |

| Real-time Capability | Provides continuous, real-time data analytics for dynamic process adjustment. | Tracks and controls manufacturing processes with immediate data feedback. |

| Use Cases | Product design validation, process optimization, failure prediction, and training simulations. | Shop floor control, work order management, compliance tracking, and resource allocation. |

| Benefits | Improved accuracy, reduced downtime, enhanced innovation, and cost savings through simulation. | Increased production efficiency, better quality assurance, regulatory compliance, and traceability. |

| Implementation Complexity | Requires advanced modeling, IoT integration, and continuous data synchronization. | Focuses on software deployment and integration with existing manufacturing systems. |

| Industry Focus | Automotive, aerospace, heavy machinery, and high-tech manufacturing sectors. | Widely applicable across discrete and process manufacturing industries. |

Which is better?

Digital twinning offers real-time simulation and predictive analytics, enabling manufacturers to optimize production processes and reduce downtime. Manufacturing Execution Systems (MES) provide comprehensive control and tracking of shop floor operations, improving workflow efficiency and quality assurance. Choosing between digital twinning and MES depends on specific manufacturing needs, with digital twinning excelling in virtual modeling and MES focusing on execution and resource management.

Connection

Digital twinning and Manufacturing Execution Systems (MES) are interconnected through real-time data integration that enhances production monitoring and control. MES collects comprehensive shop floor data, which digital twins use to create dynamic virtual replicas of physical manufacturing processes, enabling predictive analytics and optimization. This synergy improves operational efficiency, reduces downtime, and supports informed decision-making in smart manufacturing environments.

Key Terms

Real-time production monitoring

Manufacturing Execution Systems (MES) provide real-time production monitoring by tracking work-in-progress, machine performance, and resource utilization on the shop floor, enabling immediate response to operational issues. Digital twinning offers a dynamic virtual replica of physical assets and processes, allowing simulation and predictive analysis to optimize production before implementing changes in the real environment. Explore how integrating MES with digital twins can revolutionize real-time production monitoring and drive operational excellence.

Virtual simulation/model

MES (Manufacturing Execution Systems) manage real-time production data to optimize shop floor operations, while digital twinning creates virtual simulations of physical assets for predictive analysis and performance improvement. Digital twins use virtual modeling to replicate equipment behavior and process flows, enabling scenario testing without disrupting actual manufacturing. Explore how integrating MES with digital twinning can elevate operational efficiency and innovation.

Data integration

MES (Manufacturing Execution Systems) centralize real-time production data from machines, operators, and workflows to optimize shop floor operations and ensure quality control. Digital twinning creates a virtual replica of physical assets and processes, enabling simulation and predictive analysis driven by integrated sensor and IoT data streams. Explore how combining MES with digital twins enhances data integration for superior manufacturing intelligence and operational efficiency.

Source and External Links

Manufacturing execution system - MES are computerized systems that monitor and control the transformation of raw materials into finished goods in real time, improving production efficiency, quality management, and resource tracking on the plant floor.

What is a Manufacturing Execution System (MES)? - MES software bridges enterprise planning systems and shop floor operations by providing real-time visibility, control, and optimization of manufacturing processes to improve production scheduling, quality assurance, and inventory management.

The MES Beginners Guide | Rockwell Automation | Plex | US - An MES tracks real-time data throughout the production cycle, connecting machines and work centers to optimize manufacturing operations and provide detailed insights into product tracking, performance, and work in progress.

dowidth.com

dowidth.com