Lights out factories operate with fully automated processes requiring minimal human intervention, significantly boosting efficiency and reducing labor costs. Agile manufacturing emphasizes flexibility, rapid response to market changes, and customization through adaptive systems and skilled workforce collaboration. Explore these innovative approaches to understand how they transform modern production strategies.

Why it is important

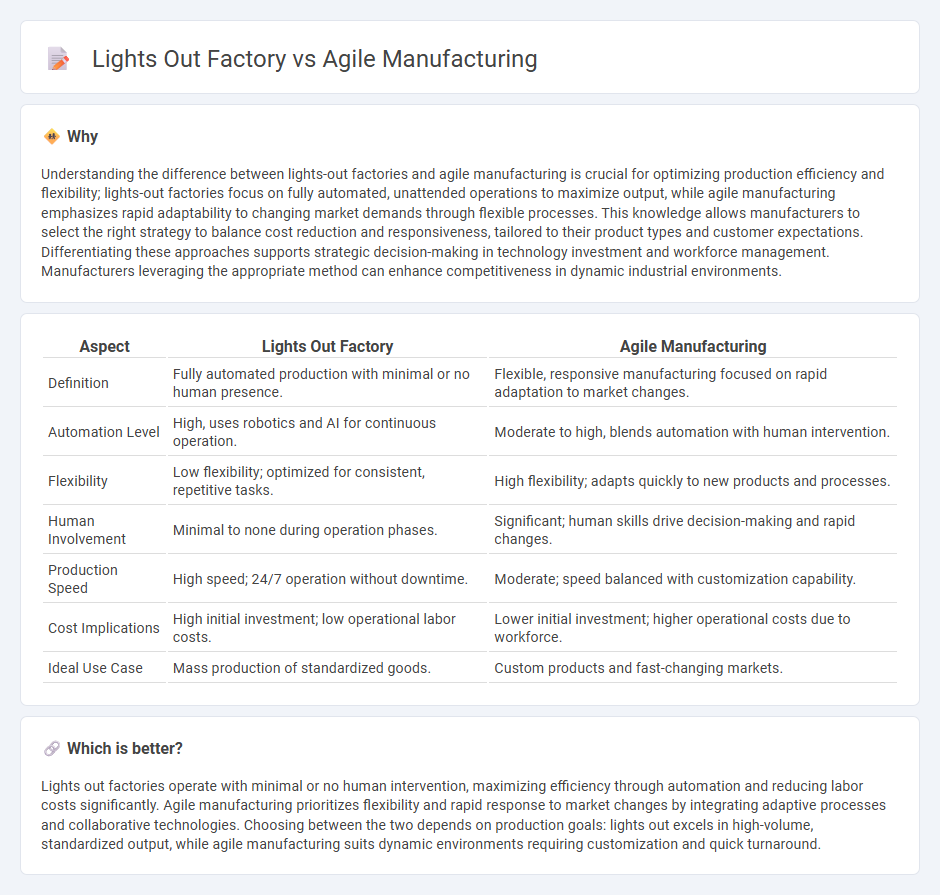

Understanding the difference between lights-out factories and agile manufacturing is crucial for optimizing production efficiency and flexibility; lights-out factories focus on fully automated, unattended operations to maximize output, while agile manufacturing emphasizes rapid adaptability to changing market demands through flexible processes. This knowledge allows manufacturers to select the right strategy to balance cost reduction and responsiveness, tailored to their product types and customer expectations. Differentiating these approaches supports strategic decision-making in technology investment and workforce management. Manufacturers leveraging the appropriate method can enhance competitiveness in dynamic industrial environments.

Comparison Table

| Aspect | Lights Out Factory | Agile Manufacturing |

|---|---|---|

| Definition | Fully automated production with minimal or no human presence. | Flexible, responsive manufacturing focused on rapid adaptation to market changes. |

| Automation Level | High, uses robotics and AI for continuous operation. | Moderate to high, blends automation with human intervention. |

| Flexibility | Low flexibility; optimized for consistent, repetitive tasks. | High flexibility; adapts quickly to new products and processes. |

| Human Involvement | Minimal to none during operation phases. | Significant; human skills drive decision-making and rapid changes. |

| Production Speed | High speed; 24/7 operation without downtime. | Moderate; speed balanced with customization capability. |

| Cost Implications | High initial investment; low operational labor costs. | Lower initial investment; higher operational costs due to workforce. |

| Ideal Use Case | Mass production of standardized goods. | Custom products and fast-changing markets. |

Which is better?

Lights out factories operate with minimal or no human intervention, maximizing efficiency through automation and reducing labor costs significantly. Agile manufacturing prioritizes flexibility and rapid response to market changes by integrating adaptive processes and collaborative technologies. Choosing between the two depends on production goals: lights out excels in high-volume, standardized output, while agile manufacturing suits dynamic environments requiring customization and quick turnaround.

Connection

Lights-out factories utilize automation and robotics to operate without human intervention, enhancing production efficiency and reducing errors. Agile manufacturing complements this by enabling rapid adaptation to changing market demands through flexible processes and scalable technology. Together, they create a highly responsive, cost-effective manufacturing environment driven by advanced digital integration.

Key Terms

**Agile Manufacturing:**

Agile manufacturing emphasizes flexibility, rapid response to market changes, and customization through adaptive processes and skilled human intervention. It integrates advanced technologies like IoT and AI to enhance collaboration and minimize lead times while maintaining product quality. Discover detailed strategies and benefits of agile manufacturing by exploring further insights.

Flexibility

Agile manufacturing emphasizes rapid adaptability and efficient response to market changes through modular processes and cross-functional teams, enhancing flexibility in production. Lights out factories rely on fully automated operations with minimal human intervention, prioritizing consistency and continuous production but often limiting dynamic adaptability. Explore deeper insights into how flexibility impacts both agile manufacturing and lights out factory models.

Rapid Response

Agile manufacturing emphasizes flexibility and quick adaptation to market changes through iterative processes and decentralized decision-making. Lights-out factories operate with fully automated production systems running without human intervention, maximizing efficiency and reducing downtime. Explore how combining agile principles with lights-out automation can revolutionize rapid response capabilities in modern manufacturing.

Source and External Links

What Is Agile Manufacturing? Lean vs. Agile - Agile manufacturing is a methodology emphasizing rapid response to customer demand, turning speed and agility into a key competitive advantage by leveraging fast changes in the market and personalization, especially valuable in high-labor-cost countries like the U.S., and often built on lean manufacturing foundations such as small-batch production and continuous improvement.

Agile Manufacturing: Benefits, Challenges, and Key Technologies - Agile manufacturing focuses on responsiveness and customization, exemplified by Dell's model of direct customer configuration, just-in-time production, and close supplier collaboration, resulting in improved quality, productivity, and shorter cycle times through speed and innovation.

Agile manufacturing - Wikipedia - Agile manufacturing is a modern production approach that enables swift and flexible responses to market changes while maintaining quality and cost control, integrating adaptability and proactive response with lean principles to meet customer demands quickly through strong supplier networks and cross-functional teams.

dowidth.com

dowidth.com