Robotic process automation (RPA) in logistics streamlines repetitive tasks such as order processing, inventory management, and shipment tracking using software bots, enhancing accuracy and efficiency without physical interaction with goods. Goods-to-person (G2P) automation physically brings items to workers via automated storage and retrieval systems, optimizing picking speed and reducing labor costs in warehouse operations. Explore how integrating RPA and G2P technologies revolutionizes supply chain performance and fulfillment strategies.

Why it is important

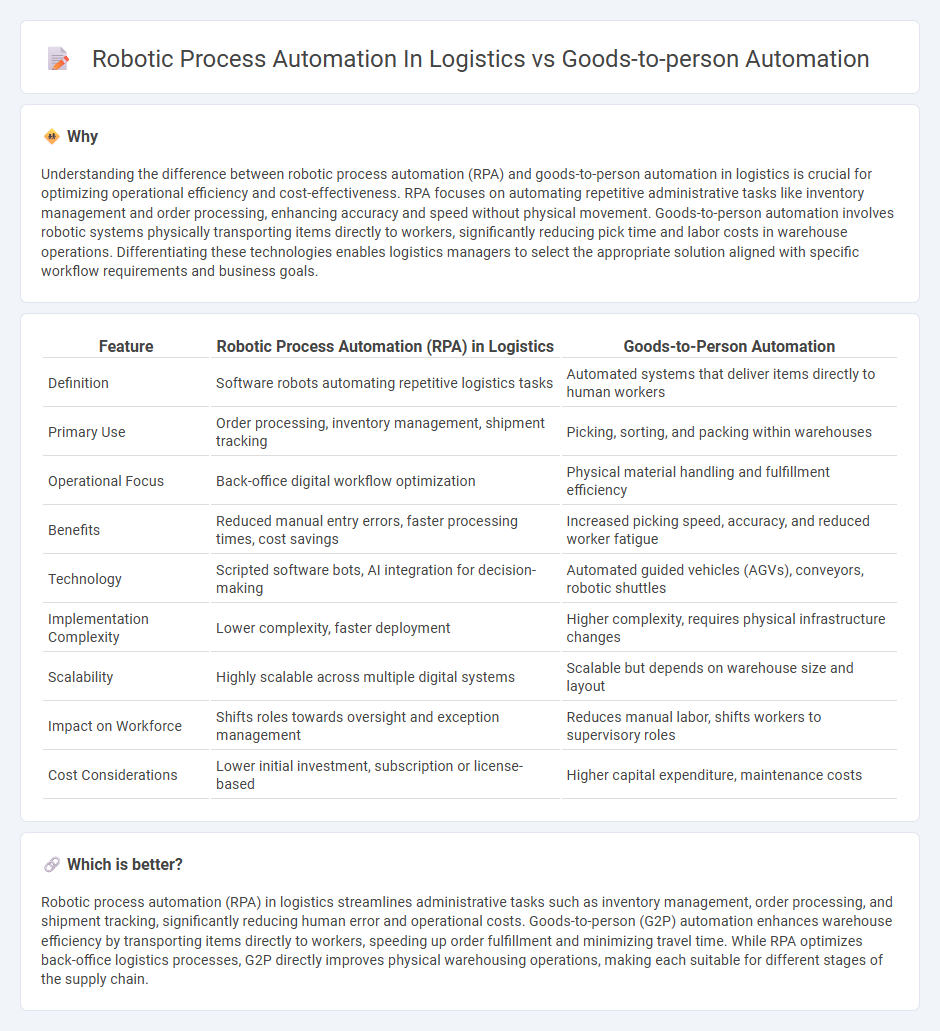

Understanding the difference between robotic process automation (RPA) and goods-to-person automation in logistics is crucial for optimizing operational efficiency and cost-effectiveness. RPA focuses on automating repetitive administrative tasks like inventory management and order processing, enhancing accuracy and speed without physical movement. Goods-to-person automation involves robotic systems physically transporting items directly to workers, significantly reducing pick time and labor costs in warehouse operations. Differentiating these technologies enables logistics managers to select the appropriate solution aligned with specific workflow requirements and business goals.

Comparison Table

| Feature | Robotic Process Automation (RPA) in Logistics | Goods-to-Person Automation |

|---|---|---|

| Definition | Software robots automating repetitive logistics tasks | Automated systems that deliver items directly to human workers |

| Primary Use | Order processing, inventory management, shipment tracking | Picking, sorting, and packing within warehouses |

| Operational Focus | Back-office digital workflow optimization | Physical material handling and fulfillment efficiency |

| Benefits | Reduced manual entry errors, faster processing times, cost savings | Increased picking speed, accuracy, and reduced worker fatigue |

| Technology | Scripted software bots, AI integration for decision-making | Automated guided vehicles (AGVs), conveyors, robotic shuttles |

| Implementation Complexity | Lower complexity, faster deployment | Higher complexity, requires physical infrastructure changes |

| Scalability | Highly scalable across multiple digital systems | Scalable but depends on warehouse size and layout |

| Impact on Workforce | Shifts roles towards oversight and exception management | Reduces manual labor, shifts workers to supervisory roles |

| Cost Considerations | Lower initial investment, subscription or license-based | Higher capital expenditure, maintenance costs |

Which is better?

Robotic process automation (RPA) in logistics streamlines administrative tasks such as inventory management, order processing, and shipment tracking, significantly reducing human error and operational costs. Goods-to-person (G2P) automation enhances warehouse efficiency by transporting items directly to workers, speeding up order fulfillment and minimizing travel time. While RPA optimizes back-office logistics processes, G2P directly improves physical warehousing operations, making each suitable for different stages of the supply chain.

Connection

Robotic process automation (RPA) in logistics enhances operational efficiency by automating repetitive tasks such as inventory management and order processing, directly complementing goods-to-person automation systems that optimize item picking and fulfillment workflows. The integration of RPA streamlines data exchange and coordination between warehouse management systems and robotic equipment, resulting in faster order turnaround and reduced human error. Together, these technologies create a cohesive, automated logistics environment that improves accuracy, reduces labor costs, and accelerates supply chain throughput.

Key Terms

**Goods-to-Person Automation:**

Goods-to-person automation in logistics enhances order fulfillment by using automated systems to deliver goods directly to workers, increasing picking accuracy and operational efficiency. This technology leverages robotics, conveyor systems, and intelligent software to minimize manual labor and optimize warehouse space utilization. Discover how integrating goods-to-person automation can transform your supply chain processes for greater speed and reliability.

Automated Storage and Retrieval System (AS/RS)

Goods-to-person automation enhances warehouse efficiency by delivering items directly to operators, reducing travel time and increasing picking accuracy, while robotic process automation (RPA) streamlines administrative logistics tasks like inventory management and order processing. Automated Storage and Retrieval System (AS/RS) integrates goods-to-person technology by using robotic shuttles or cranes to store and retrieve items, optimizing inventory space and speeding up order fulfillment. Explore the latest advancements in AS/RS and their impact on logistics automation.

Pick-to-Light Systems

Goods-to-person automation optimizes warehouse efficiency by transporting items directly to workers, significantly reducing travel time and increasing order accuracy. Pick-to-Light systems enhance this approach with visual cues that guide operators to the correct items, streamlining picking processes and minimizing errors. Explore how integrating Pick-to-Light with robotic process automation can revolutionize logistics operations.

Source and External Links

The Many Benefits of Goods-to-Person Automation - This article discusses how Goods-to-Person (GTP) systems improve efficiency and reduce errors by automating the picking process in warehouses.

Goods-to-Person Order Fulfillment - Goods-to-Person (GTP) solutions combine automated storage and retrieval with ergonomic picking processes to enhance efficiency and accuracy.

Complete Guide to Goods-to-Person Automation - This guide outlines the benefits of Goods-to-Person systems, including increased productivity, improved accuracy, and optimized warehouse space utilization.

dowidth.com

dowidth.com