Reverse logistics focuses on managing the flow of goods from customers back to sellers for returns, recycling, or disposal, enhancing sustainability and reducing waste. Returnable packaging involves containers or materials designed for multiple uses in the supply chain, improving cost efficiency and environmental impact. Discover how integrating reverse logistics with returnable packaging can optimize supply chain performance.

Why it is important

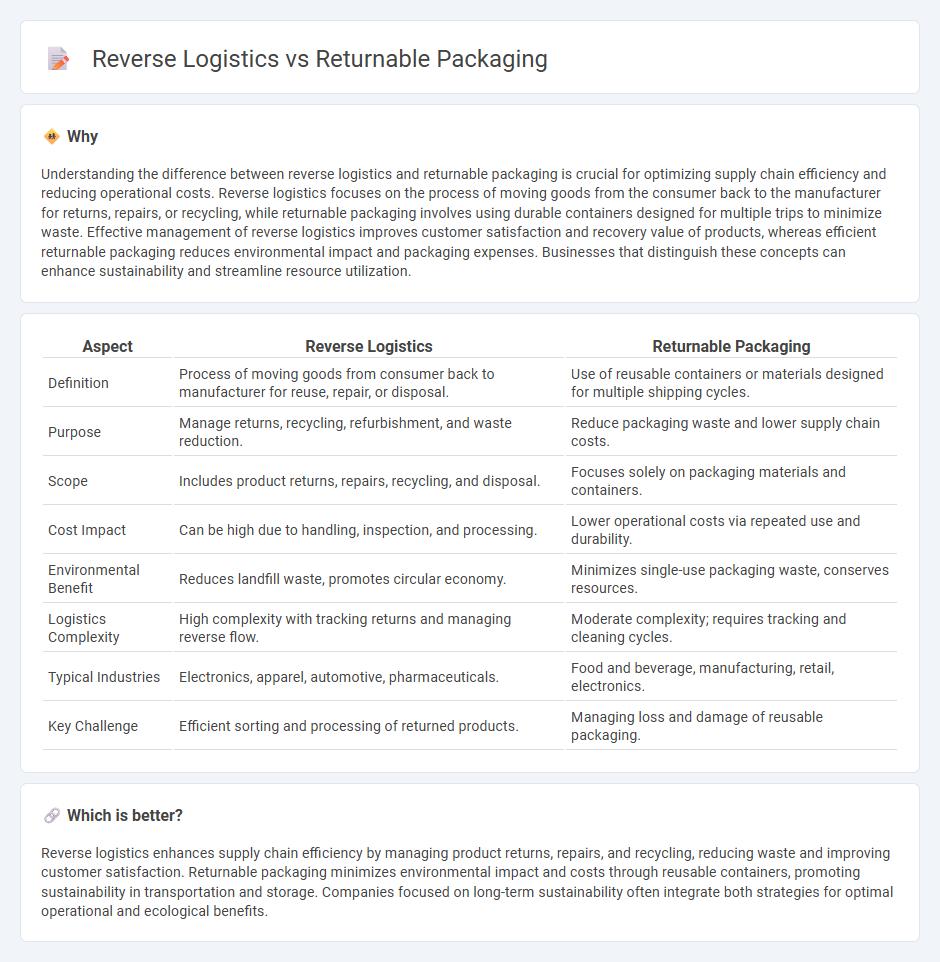

Understanding the difference between reverse logistics and returnable packaging is crucial for optimizing supply chain efficiency and reducing operational costs. Reverse logistics focuses on the process of moving goods from the consumer back to the manufacturer for returns, repairs, or recycling, while returnable packaging involves using durable containers designed for multiple trips to minimize waste. Effective management of reverse logistics improves customer satisfaction and recovery value of products, whereas efficient returnable packaging reduces environmental impact and packaging expenses. Businesses that distinguish these concepts can enhance sustainability and streamline resource utilization.

Comparison Table

| Aspect | Reverse Logistics | Returnable Packaging |

|---|---|---|

| Definition | Process of moving goods from consumer back to manufacturer for reuse, repair, or disposal. | Use of reusable containers or materials designed for multiple shipping cycles. |

| Purpose | Manage returns, recycling, refurbishment, and waste reduction. | Reduce packaging waste and lower supply chain costs. |

| Scope | Includes product returns, repairs, recycling, and disposal. | Focuses solely on packaging materials and containers. |

| Cost Impact | Can be high due to handling, inspection, and processing. | Lower operational costs via repeated use and durability. |

| Environmental Benefit | Reduces landfill waste, promotes circular economy. | Minimizes single-use packaging waste, conserves resources. |

| Logistics Complexity | High complexity with tracking returns and managing reverse flow. | Moderate complexity; requires tracking and cleaning cycles. |

| Typical Industries | Electronics, apparel, automotive, pharmaceuticals. | Food and beverage, manufacturing, retail, electronics. |

| Key Challenge | Efficient sorting and processing of returned products. | Managing loss and damage of reusable packaging. |

Which is better?

Reverse logistics enhances supply chain efficiency by managing product returns, repairs, and recycling, reducing waste and improving customer satisfaction. Returnable packaging minimizes environmental impact and costs through reusable containers, promoting sustainability in transportation and storage. Companies focused on long-term sustainability often integrate both strategies for optimal operational and ecological benefits.

Connection

Reverse logistics involves the process of moving goods from their final destination back to the manufacturer or warehouse for reuse, refurbishment, or disposal. Returnable packaging plays a crucial role in reverse logistics by facilitating efficient and sustainable transportation of returned products, reducing waste and operational costs. Together, they optimize supply chain efficiency and promote environmental responsibility through reusable containers and streamlined return processes.

Key Terms

Asset Tracking

Returnable packaging systems enhance asset tracking by enabling precise monitoring of reusable containers throughout the supply chain, reducing loss and damage while optimizing turnaround times. Reverse logistics processes rely heavily on accurate asset tracking to ensure efficient return, inspection, and refurbishment of packaging assets, minimizing operational costs and environmental impact. Discover how integrating advanced asset tracking technologies can transform your returnable packaging and reverse logistics strategies.

Reuse Cycle

Returnable packaging enhances sustainability by enabling multiple reuse cycles, significantly reducing waste and lowering packaging costs. Reverse logistics supports this system by efficiently managing the return, inspection, cleaning, and redistribution of packaging materials. Explore how optimizing the reuse cycle within returnable packaging can improve supply chain efficiency and environmental impact.

Product Recovery

Returnable packaging plays a crucial role in enhancing product recovery by facilitating repeated use and minimizing waste in supply chains, whereas reverse logistics encompasses the broader process of managing the return, reuse, and disposal of products. Returnable packaging ensures product integrity during transportation and handling, directly influencing the efficiency of asset recovery and refurbishment efforts. Explore how integrating returnable packaging with reverse logistics strategies can optimize product recovery and sustainable supply chain management.

Source and External Links

Reusable packaging - Returnable packaging refers to durable packaging designed for multiple trips and extended life, often made from materials like steel, wood, or plastic, and is integral to sustainability by promoting reuse rather than single-use disposal.

Returnable packaging | Strategy& - Returnable packaging is a type of durable, reusable packaging used repeatedly for the same purpose, often involving a deposit system to encourage return and reuse, contributing significantly to circular economy goals but requiring system-wide integration to maximize benefits.

Returnable Packaging Vs. Expendable Packaging - Returnable packaging is favored for its environmental sustainability, superior product protection, durability, and cost efficiency, with some reusable containers lasting 100 or more uses, making them a preferred alternative to expendable packaging.

dowidth.com

dowidth.com