Pick to light systems enhance order accuracy and speed by guiding operators with illuminated indicators at each pick location, improving manual picking efficiency in warehouses. Automated guided vehicles (AGVs) automate material transport, reducing labor costs and increasing throughput by navigating predefined paths without human intervention. Explore how integrating pick to light systems and AGVs can optimize your logistics operations for maximum productivity.

Why it is important

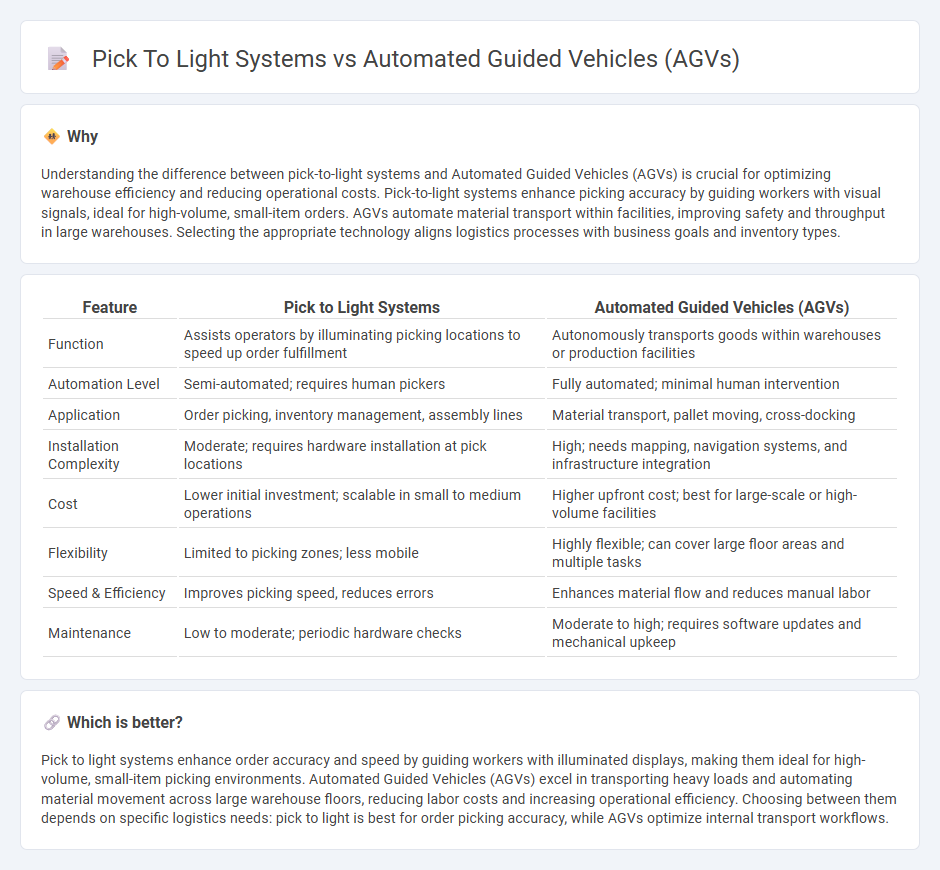

Understanding the difference between pick-to-light systems and Automated Guided Vehicles (AGVs) is crucial for optimizing warehouse efficiency and reducing operational costs. Pick-to-light systems enhance picking accuracy by guiding workers with visual signals, ideal for high-volume, small-item orders. AGVs automate material transport within facilities, improving safety and throughput in large warehouses. Selecting the appropriate technology aligns logistics processes with business goals and inventory types.

Comparison Table

| Feature | Pick to Light Systems | Automated Guided Vehicles (AGVs) |

|---|---|---|

| Function | Assists operators by illuminating picking locations to speed up order fulfillment | Autonomously transports goods within warehouses or production facilities |

| Automation Level | Semi-automated; requires human pickers | Fully automated; minimal human intervention |

| Application | Order picking, inventory management, assembly lines | Material transport, pallet moving, cross-docking |

| Installation Complexity | Moderate; requires hardware installation at pick locations | High; needs mapping, navigation systems, and infrastructure integration |

| Cost | Lower initial investment; scalable in small to medium operations | Higher upfront cost; best for large-scale or high-volume facilities |

| Flexibility | Limited to picking zones; less mobile | Highly flexible; can cover large floor areas and multiple tasks |

| Speed & Efficiency | Improves picking speed, reduces errors | Enhances material flow and reduces manual labor |

| Maintenance | Low to moderate; periodic hardware checks | Moderate to high; requires software updates and mechanical upkeep |

Which is better?

Pick to light systems enhance order accuracy and speed by guiding workers with illuminated displays, making them ideal for high-volume, small-item picking environments. Automated Guided Vehicles (AGVs) excel in transporting heavy loads and automating material movement across large warehouse floors, reducing labor costs and increasing operational efficiency. Choosing between them depends on specific logistics needs: pick to light is best for order picking accuracy, while AGVs optimize internal transport workflows.

Connection

Pick to light systems and Automated Guided Vehicles (AGVs) are integrated to enhance warehouse automation by streamlining order fulfillment and material handling. Pick to light technology guides operators to precise item locations, while AGVs transport goods efficiently between workstations, reducing human labor and errors. This synergy increases operational speed, accuracy, and overall logistics productivity in distribution centers.

Key Terms

Material Handling

Automated Guided Vehicles (AGVs) streamline material handling by autonomously transporting goods, reducing labor costs, and enhancing warehouse efficiency with precise navigation technology. Pick to Light systems optimize order fulfillment accuracy by using visual indicators to guide operators directly to the correct items, accelerating picking processes and minimizing errors. Explore the benefits of integrating AGVs and Pick to Light systems to revolutionize your material handling operations.

Order Fulfillment

Automated guided vehicles (AGVs) enhance order fulfillment by enabling efficient material transport and reducing manual labor, leading to faster and more accurate warehouse operations. Pick to light systems optimize picking accuracy and speed by using visual signals, which minimize errors and improve worker productivity in order processing. Explore detailed comparisons to determine the best solution for your order fulfillment needs.

Warehouse Automation

Automated guided vehicles (AGVs) enhance warehouse automation by providing flexible, efficient material transport with minimal human intervention, while pick-to-light systems optimize picking accuracy and speed through visual guidance and real-time feedback. AGVs excel in reducing labor costs and improving safety in large-scale operations, whereas pick-to-light systems boost order fulfillment precision and reduce errors in picking processes. Explore how integrating AGVs with pick-to-light systems can revolutionize warehouse productivity and accuracy.

Source and External Links

What Are Automated Guided Vehicles (AGVs)? - Spectra by MHI - AGVs are autonomous, driverless material-handling machines used in warehouses, factories, and hospitals to move goods efficiently using internal navigation systems and central control software to automate repetitive tasks and address labor shortages.

Fundamentals of Automated Guided Vehicles - Cyngn - AGVs are robotic vehicles designed to autonomously transport materials in industrial settings, operating on fixed routes with infrastructure like charging stations and control software, distinguishing them from more flexible AMRs which navigate dynamically.

AGV Manufacturers | AGV Suppliers | Automatic Guided Vehicles - Artificial intelligence is enhancing AGVs by enabling dynamic navigation, predictive maintenance, task versatility, and improved human-robot collaboration, allowing AGVs to adapt routes autonomously, optimize fleet operations, and increase safety in complex environments.

dowidth.com

dowidth.com