Reverse logistics solutions focus on managing returns, recycling, and waste disposal, optimizing the flow of goods from customers back to sellers or manufacturers. Order fulfillment involves the entire process of receiving, processing, and delivering customer orders accurately and efficiently. Explore how integrating reverse logistics with order fulfillment can enhance supply chain sustainability and customer satisfaction.

Why it is important

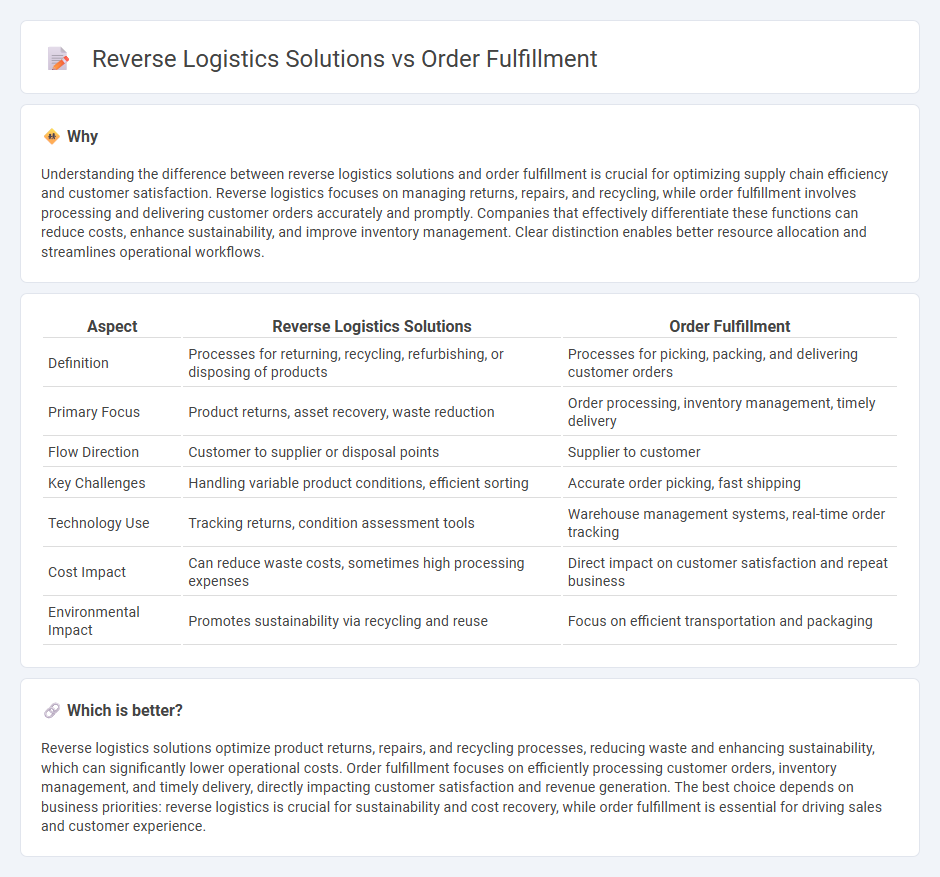

Understanding the difference between reverse logistics solutions and order fulfillment is crucial for optimizing supply chain efficiency and customer satisfaction. Reverse logistics focuses on managing returns, repairs, and recycling, while order fulfillment involves processing and delivering customer orders accurately and promptly. Companies that effectively differentiate these functions can reduce costs, enhance sustainability, and improve inventory management. Clear distinction enables better resource allocation and streamlines operational workflows.

Comparison Table

| Aspect | Reverse Logistics Solutions | Order Fulfillment |

|---|---|---|

| Definition | Processes for returning, recycling, refurbishing, or disposing of products | Processes for picking, packing, and delivering customer orders |

| Primary Focus | Product returns, asset recovery, waste reduction | Order processing, inventory management, timely delivery |

| Flow Direction | Customer to supplier or disposal points | Supplier to customer |

| Key Challenges | Handling variable product conditions, efficient sorting | Accurate order picking, fast shipping |

| Technology Use | Tracking returns, condition assessment tools | Warehouse management systems, real-time order tracking |

| Cost Impact | Can reduce waste costs, sometimes high processing expenses | Direct impact on customer satisfaction and repeat business |

| Environmental Impact | Promotes sustainability via recycling and reuse | Focus on efficient transportation and packaging |

Which is better?

Reverse logistics solutions optimize product returns, repairs, and recycling processes, reducing waste and enhancing sustainability, which can significantly lower operational costs. Order fulfillment focuses on efficiently processing customer orders, inventory management, and timely delivery, directly impacting customer satisfaction and revenue generation. The best choice depends on business priorities: reverse logistics is crucial for sustainability and cost recovery, while order fulfillment is essential for driving sales and customer experience.

Connection

Reverse logistics solutions enhance order fulfillment by efficiently managing product returns, refurbishments, and recycling, thereby improving customer satisfaction and reducing waste. Streamlined reverse logistics processes minimize delays and costs associated with return handling, ensuring timely replenishment of inventory and accurate order processing. Integrating reverse logistics within order fulfillment systems supports sustainability goals and drives operational efficiency across the supply chain.

Key Terms

**Order Fulfillment:**

Order fulfillment involves the comprehensive process of receiving, processing, and delivering customer orders efficiently, ensuring accuracy and timely shipping to enhance customer satisfaction. Key components include inventory management, picking, packing, shipping, and real-time tracking, which optimize supply chain performance and reduce operational costs. Discover more about how advanced order fulfillment solutions can transform your business operations and customer experience.

Inventory Management

Order fulfillment relies on efficient inventory management to ensure accurate stock levels and timely product dispatch, reducing stockouts and excess inventory. Reverse logistics solutions prioritize tracking returned goods and refurbishing or redistributing inventory to minimize losses and optimize warehouse space. Explore how integrated inventory management improves both order fulfillment and reverse logistics performance.

Pick and Pack

Order fulfillment focuses on efficiently picking and packing products to meet customer demand, ensuring accuracy and speed in shipment preparation. Reverse logistics solutions handle the return process, including the re-receiving, inspection, and restocking or disposal of items. Explore more to understand how optimizing pick and pack operations can enhance both forward and reverse logistics efficiency.

Source and External Links

Order Fulfillment: Meaning, Process, and How To Optimize - Order fulfillment is the entire process of receiving customer orders, processing them, packaging, shipping products, and providing tracking, involving steps like receiving customer information, storing inventory securely for picking, and preparing products for shipping to ensure accurate delivery.

Order Fulfillment Process: Definition and 7 Key Steps - Order fulfillment is a method companies use to receive, count, inspect, store, and ship inventory efficiently to customers, with key phases including inventory receiving, storing, and preparing items to ensure timely and accurate deliveries.

What Is Order Fulfillment? Improve Your Process & Strategy - Order fulfillment covers the whole journey from receiving inventory from suppliers, processing customer orders, picking and packing products accurately, to shipping and delivery, with businesses adapting the process to their specific operational needs.

dowidth.com

dowidth.com