Urban warehouses offer strategic advantages for faster delivery and inventory management by positioning storage closer to high-demand consumer areas. Retail backroom storage is limited in space and primarily supports immediate in-store restocking rather than large-scale distribution. Explore the key differences and benefits to optimize your supply chain efficiency.

Why it is important

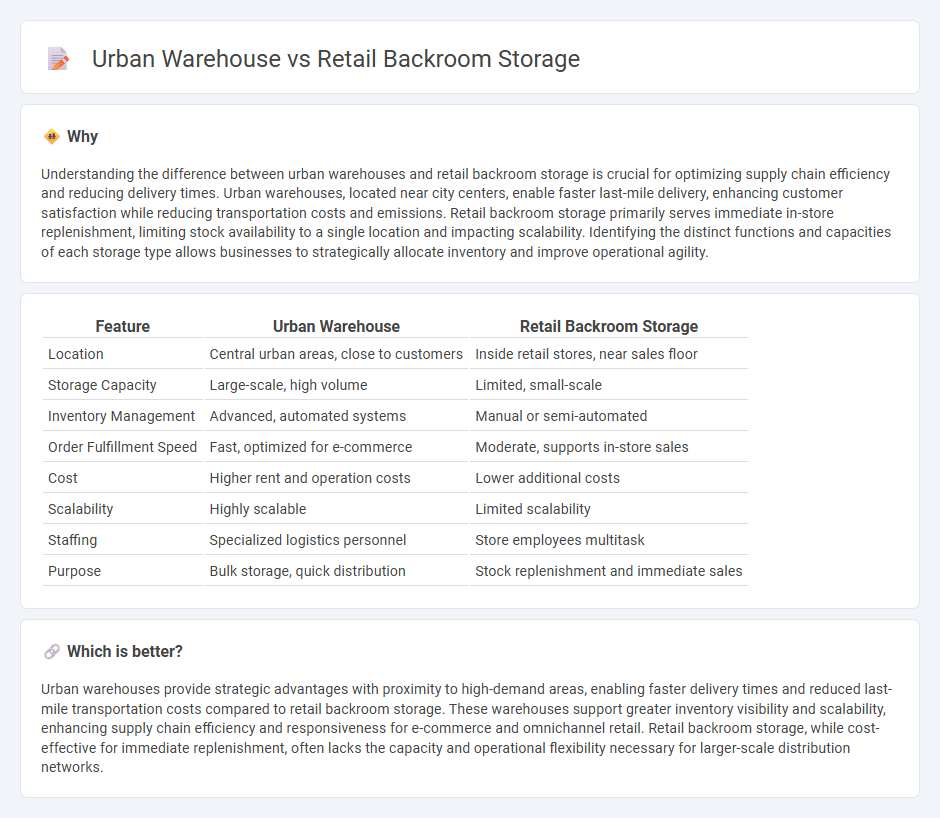

Understanding the difference between urban warehouses and retail backroom storage is crucial for optimizing supply chain efficiency and reducing delivery times. Urban warehouses, located near city centers, enable faster last-mile delivery, enhancing customer satisfaction while reducing transportation costs and emissions. Retail backroom storage primarily serves immediate in-store replenishment, limiting stock availability to a single location and impacting scalability. Identifying the distinct functions and capacities of each storage type allows businesses to strategically allocate inventory and improve operational agility.

Comparison Table

| Feature | Urban Warehouse | Retail Backroom Storage |

|---|---|---|

| Location | Central urban areas, close to customers | Inside retail stores, near sales floor |

| Storage Capacity | Large-scale, high volume | Limited, small-scale |

| Inventory Management | Advanced, automated systems | Manual or semi-automated |

| Order Fulfillment Speed | Fast, optimized for e-commerce | Moderate, supports in-store sales |

| Cost | Higher rent and operation costs | Lower additional costs |

| Scalability | Highly scalable | Limited scalability |

| Staffing | Specialized logistics personnel | Store employees multitask |

| Purpose | Bulk storage, quick distribution | Stock replenishment and immediate sales |

Which is better?

Urban warehouses provide strategic advantages with proximity to high-demand areas, enabling faster delivery times and reduced last-mile transportation costs compared to retail backroom storage. These warehouses support greater inventory visibility and scalability, enhancing supply chain efficiency and responsiveness for e-commerce and omnichannel retail. Retail backroom storage, while cost-effective for immediate replenishment, often lacks the capacity and operational flexibility necessary for larger-scale distribution networks.

Connection

Urban warehouses and retail backroom storage are integrated to streamline inventory management and enhance product availability, enabling faster replenishment and reducing stockouts. Leveraging real-time data and proximity, urban warehouses act as decentralized hubs that support backroom storage with rapid order fulfillment and optimized space utilization. This connectivity improves supply chain efficiency by minimizing transportation costs and accelerating delivery times within dense metropolitan markets.

Key Terms

**Retail Backroom Storage:**

Retail backroom storage maximizes space within stores to hold inventory, enabling quicker restocking and reducing out-of-stock situations. It typically involves smaller, highly accessible storage areas designed for immediate operational needs, unlike larger urban warehouses that serve broader distribution purposes. Explore how optimizing retail backroom storage can enhance inventory management and improve customer satisfaction.

Inventory Turnover

Retail backroom storage typically supports immediate replenishment with faster inventory turnover rates due to proximity to sales floors, optimizing product availability for customers. Urban warehouses, situated closer to transportation hubs, enable bulk storage and efficient distribution, which can moderate turnover speed but improve overall supply chain responsiveness. Explore detailed comparisons to enhance inventory strategies tailored to your retail operations.

Stock Replenishment

Retail backroom storage offers immediate proximity to the sales floor, enabling faster stock replenishment and reducing out-of-stock scenarios for high-demand products. Urban warehouses, strategically located near city centers, facilitate quicker deliveries and support just-in-time inventory approaches for multiple retail locations. Explore how optimizing stock replenishment through these storage solutions can enhance supply chain efficiency and customer satisfaction.

Source and External Links

4 Backroom Storage Shelving Options for Retail Inventories | REB - Retail backroom storage typically uses shelving such as boltless rivet, wire, gravity flow, and steel shelving to store overflow inventory and facilitate quick restocking.

Backroom Storage Shelving - Midwest Retail Services - Backroom shelving made of galvanized steel and industrial particleboard provides configurable, durable storage solutions to keep merchandise organized and ready for restocking.

Used Backroom Shelving | Stockroom and Retail Shelving for Sale - Backroom shelving is designed for practicality with clipless, easy assembly steel frame units often featuring wire or reinforced particleboard shelves, offering affordable, expandable storage for retail stockrooms.

dowidth.com

dowidth.com