Cold chain traceability ensures the precise monitoring of temperature-sensitive products throughout the supply chain, reducing spoilage and maintaining product quality. Inventory management focuses on optimizing stock levels, minimizing holding costs, and improving order fulfillment accuracy. Discover how these critical logistics components enhance operational efficiency and customer satisfaction.

Why it is important

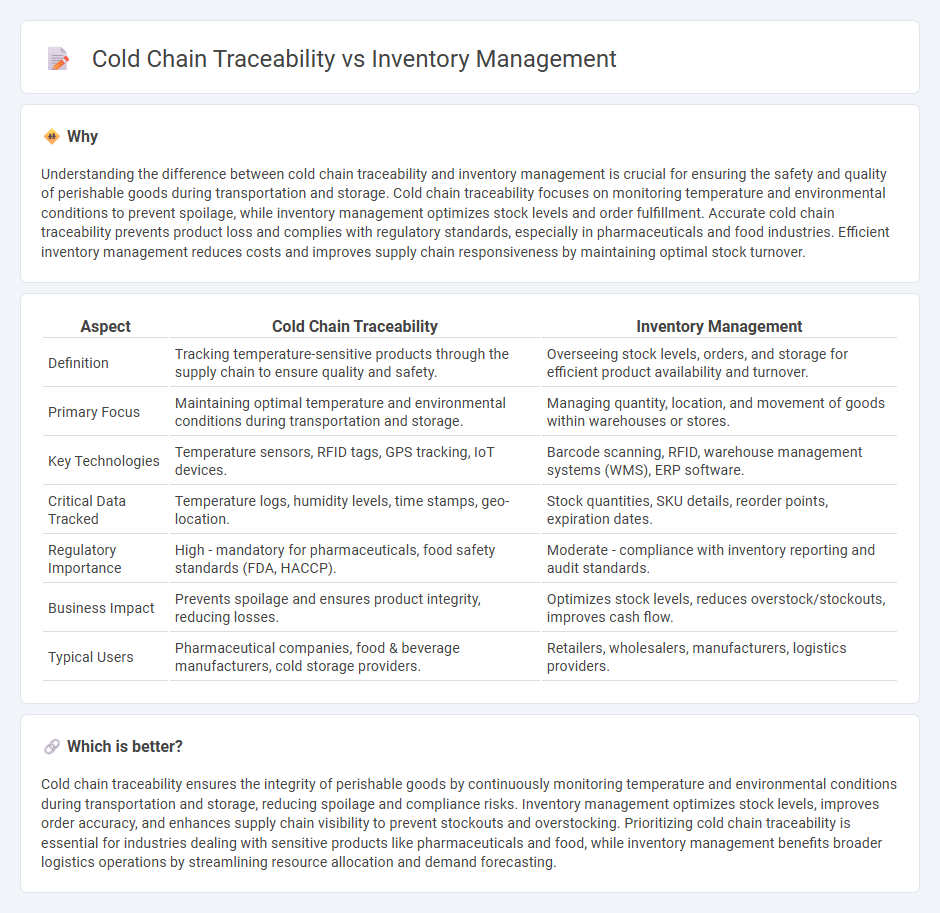

Understanding the difference between cold chain traceability and inventory management is crucial for ensuring the safety and quality of perishable goods during transportation and storage. Cold chain traceability focuses on monitoring temperature and environmental conditions to prevent spoilage, while inventory management optimizes stock levels and order fulfillment. Accurate cold chain traceability prevents product loss and complies with regulatory standards, especially in pharmaceuticals and food industries. Efficient inventory management reduces costs and improves supply chain responsiveness by maintaining optimal stock turnover.

Comparison Table

| Aspect | Cold Chain Traceability | Inventory Management |

|---|---|---|

| Definition | Tracking temperature-sensitive products through the supply chain to ensure quality and safety. | Overseeing stock levels, orders, and storage for efficient product availability and turnover. |

| Primary Focus | Maintaining optimal temperature and environmental conditions during transportation and storage. | Managing quantity, location, and movement of goods within warehouses or stores. |

| Key Technologies | Temperature sensors, RFID tags, GPS tracking, IoT devices. | Barcode scanning, RFID, warehouse management systems (WMS), ERP software. |

| Critical Data Tracked | Temperature logs, humidity levels, time stamps, geo-location. | Stock quantities, SKU details, reorder points, expiration dates. |

| Regulatory Importance | High - mandatory for pharmaceuticals, food safety standards (FDA, HACCP). | Moderate - compliance with inventory reporting and audit standards. |

| Business Impact | Prevents spoilage and ensures product integrity, reducing losses. | Optimizes stock levels, reduces overstock/stockouts, improves cash flow. |

| Typical Users | Pharmaceutical companies, food & beverage manufacturers, cold storage providers. | Retailers, wholesalers, manufacturers, logistics providers. |

Which is better?

Cold chain traceability ensures the integrity of perishable goods by continuously monitoring temperature and environmental conditions during transportation and storage, reducing spoilage and compliance risks. Inventory management optimizes stock levels, improves order accuracy, and enhances supply chain visibility to prevent stockouts and overstocking. Prioritizing cold chain traceability is essential for industries dealing with sensitive products like pharmaceuticals and food, while inventory management benefits broader logistics operations by streamlining resource allocation and demand forecasting.

Connection

Cold chain traceability ensures real-time monitoring of temperature-sensitive products, which directly impacts inventory accuracy and reduces spoilage risks. Integrating precise cold chain data with inventory management systems improves stock visibility, streamlines replenishment processes, and enhances compliance with regulatory standards. Effective synchronization between cold chain monitoring and inventory control minimizes waste and optimizes supply chain efficiency.

Key Terms

**Inventory Management:**

Inventory management optimizes stock levels, reduces carrying costs, and enhances order accuracy through real-time tracking systems and demand forecasting algorithms. Effective inventory management integrates barcode scanning, RFID technology, and automated replenishment to streamline supply chain operations and minimize stockouts. Discover how advanced inventory management solutions can transform your business efficiency and profitability.

Stock Keeping Unit (SKU)

Effective inventory management ensures accurate Stock Keeping Unit (SKU) tracking, optimizing stock levels and reducing holding costs. Cold chain traceability specifically monitors SKU conditions, such as temperature and humidity, during storage and transit to maintain product quality and compliance. Explore advanced solutions to integrate SKU management with cold chain traceability for enhanced operational efficiency and safety.

Reorder Point (ROP)

Inventory management relies on Reorder Point (ROP) to ensure stock levels trigger replenishment just in time, preventing stockouts and minimizing holding costs. Cold chain traceability enhances ROP efficiency by monitoring temperature-sensitive products throughout the supply chain, maintaining product quality and compliance with regulatory standards. Explore how integrating cold chain traceability with inventory management optimizes ROP strategies for superior operational control.

Source and External Links

What Is Inventory Management? Benefits, Types, & Techniques - Inventory management is the process of tracking and controlling the flow of goods, involving demand planning, ordering, delivery, storage, sales, reviewing, and replenishment to optimize inventory and supply chain efficiency.

Inventory Management: How it Works and Tools (2025) - Shopify - Effective inventory management uses techniques such as Economic Order Quantity, demand planning, and safety stock alerts to balance stock levels, improve cash flow, and meet customer demand without overstocking or stockouts.

Inventory Management Guide + Methods & Examples - Extensiv - Inventory management methods include manual spreadsheets, automated systems with RFID and computer vision, ERP software, and multichannel management to organize sourcing, storage, and sales across multiple platforms and locations.

dowidth.com

dowidth.com