Cold chain visibility involves real-time tracking and monitoring of temperature-sensitive goods throughout the supply chain to ensure product integrity. Cold chain compliance focuses on adhering to regulatory standards and protocols that govern the storage, handling, and transportation of perishable items. Explore how integrating advanced tracking technologies enhances both visibility and compliance in cold chain logistics.

Why it is important

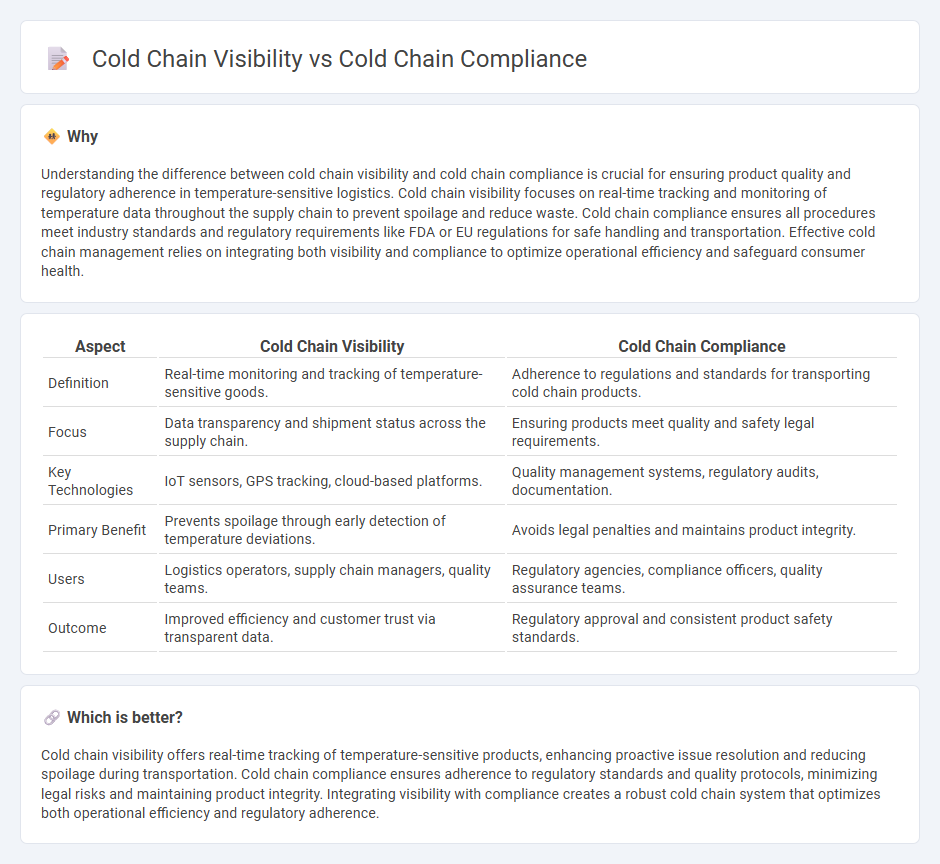

Understanding the difference between cold chain visibility and cold chain compliance is crucial for ensuring product quality and regulatory adherence in temperature-sensitive logistics. Cold chain visibility focuses on real-time tracking and monitoring of temperature data throughout the supply chain to prevent spoilage and reduce waste. Cold chain compliance ensures all procedures meet industry standards and regulatory requirements like FDA or EU regulations for safe handling and transportation. Effective cold chain management relies on integrating both visibility and compliance to optimize operational efficiency and safeguard consumer health.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Compliance |

|---|---|---|

| Definition | Real-time monitoring and tracking of temperature-sensitive goods. | Adherence to regulations and standards for transporting cold chain products. |

| Focus | Data transparency and shipment status across the supply chain. | Ensuring products meet quality and safety legal requirements. |

| Key Technologies | IoT sensors, GPS tracking, cloud-based platforms. | Quality management systems, regulatory audits, documentation. |

| Primary Benefit | Prevents spoilage through early detection of temperature deviations. | Avoids legal penalties and maintains product integrity. |

| Users | Logistics operators, supply chain managers, quality teams. | Regulatory agencies, compliance officers, quality assurance teams. |

| Outcome | Improved efficiency and customer trust via transparent data. | Regulatory approval and consistent product safety standards. |

Which is better?

Cold chain visibility offers real-time tracking of temperature-sensitive products, enhancing proactive issue resolution and reducing spoilage during transportation. Cold chain compliance ensures adherence to regulatory standards and quality protocols, minimizing legal risks and maintaining product integrity. Integrating visibility with compliance creates a robust cold chain system that optimizes both operational efficiency and regulatory adherence.

Connection

Cold chain visibility enhances cold chain compliance by providing real-time tracking and monitoring of temperature-sensitive products throughout the logistics process. This continuous oversight ensures adherence to regulatory requirements and industry standards, minimizing spoilage and maintaining product integrity. Effective visibility tools enable prompt corrective actions, reducing risks associated with temperature deviations and ensuring product safety from origin to destination.

Key Terms

**Cold Chain Compliance:**

Cold chain compliance ensures strict adherence to regulatory standards and temperature control protocols throughout the supply chain, minimizing risks of product spoilage and ensuring safety for pharmaceuticals and perishable goods. It involves continuous monitoring, documentation, and corrective actions to meet industry guidelines like FDA and WHO standards. Explore how maintaining cold chain compliance can protect your products and enhance supply chain reliability.

Regulatory Standards

Cold chain compliance ensures adherence to strict regulatory standards set by authorities such as the FDA, WHO, and EU for temperature control during storage and transportation of pharmaceuticals and perishable goods. Cold chain visibility refers to real-time monitoring and data logging technologies that provide transparent tracking of temperature, location, and handling, enhancing the ability to meet compliance requirements effectively. Explore how integrating cold chain visibility tools can streamline compliance efforts and safeguard product integrity.

Audit Documentation

Cold chain compliance focuses on adhering to regulatory standards and maintaining thorough audit documentation to ensure product integrity during storage and transport. Cold chain visibility emphasizes real-time tracking and monitoring of temperature data to provide transparency and proactive risk management. Explore effective strategies for integrating audit documentation with cold chain visibility to enhance overall supply chain reliability.

Source and External Links

Building a Compliant Cold Chain - A compliant cold chain protects temperature-sensitive medication against temperature excursions, tampering, and human error by implementing a comprehensive toolkit of packaging, processes, technologies, and expertise to ensure regulatory compliance, risk mitigation, and patient safety in pharmaceutical logistics.

Cold chain: what it is, management, and regulations - Cold chain compliance involves strict monitoring and recording of product temperatures during storage and transport under regulations such as HACCP for food safety and stringent pharmaceutical guidelines to maintain product efficacy and safety.

Cold Chain Compliance: Ensuring Safety from Production to Delivery - Cold chain compliance requires adherence to global (e.g., WHO) and regional regulations ensuring temperature-sensitive products are handled safely across different climates worldwide, with best practices focused on continuous temperature control, monitoring, and documentation to prevent product spoilage and legal issues.

dowidth.com

dowidth.com