Cold chain traceability ensures continuous monitoring of temperature-sensitive products during transportation and storage, reducing spoilage and enhancing safety. Quality control in logistics involves systematic inspection and testing to maintain product standards and compliance with regulations. Explore how integrating cold chain traceability with quality control can optimize supply chain efficiency and product integrity.

Why it is important

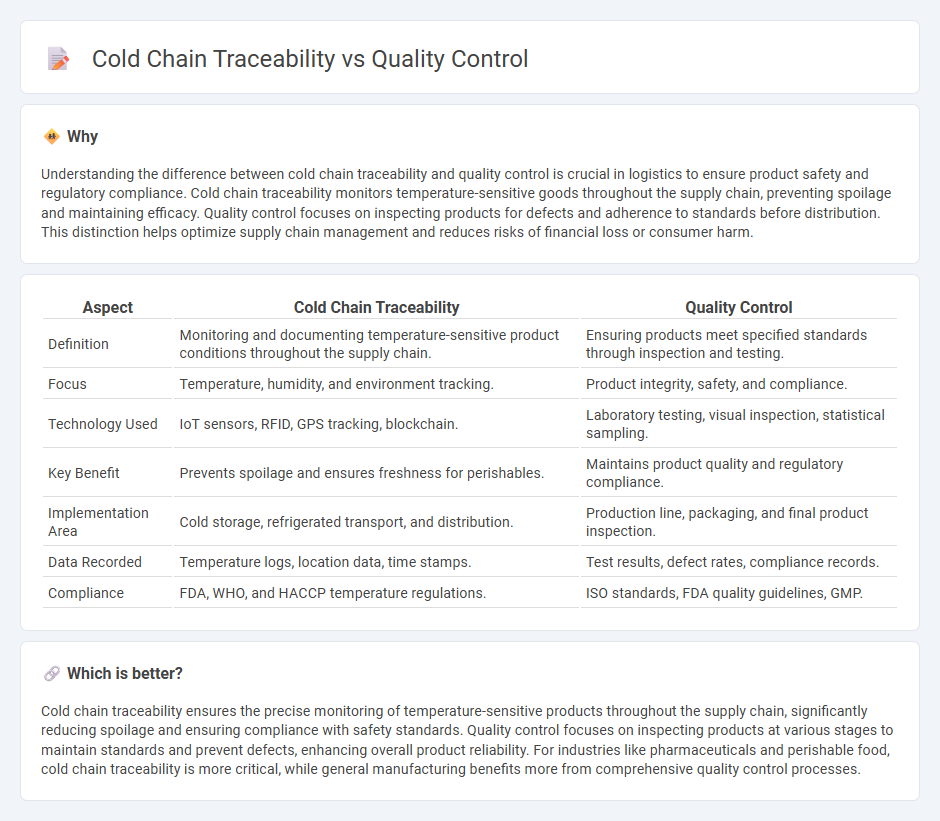

Understanding the difference between cold chain traceability and quality control is crucial in logistics to ensure product safety and regulatory compliance. Cold chain traceability monitors temperature-sensitive goods throughout the supply chain, preventing spoilage and maintaining efficacy. Quality control focuses on inspecting products for defects and adherence to standards before distribution. This distinction helps optimize supply chain management and reduces risks of financial loss or consumer harm.

Comparison Table

| Aspect | Cold Chain Traceability | Quality Control |

|---|---|---|

| Definition | Monitoring and documenting temperature-sensitive product conditions throughout the supply chain. | Ensuring products meet specified standards through inspection and testing. |

| Focus | Temperature, humidity, and environment tracking. | Product integrity, safety, and compliance. |

| Technology Used | IoT sensors, RFID, GPS tracking, blockchain. | Laboratory testing, visual inspection, statistical sampling. |

| Key Benefit | Prevents spoilage and ensures freshness for perishables. | Maintains product quality and regulatory compliance. |

| Implementation Area | Cold storage, refrigerated transport, and distribution. | Production line, packaging, and final product inspection. |

| Data Recorded | Temperature logs, location data, time stamps. | Test results, defect rates, compliance records. |

| Compliance | FDA, WHO, and HACCP temperature regulations. | ISO standards, FDA quality guidelines, GMP. |

Which is better?

Cold chain traceability ensures the precise monitoring of temperature-sensitive products throughout the supply chain, significantly reducing spoilage and ensuring compliance with safety standards. Quality control focuses on inspecting products at various stages to maintain standards and prevent defects, enhancing overall product reliability. For industries like pharmaceuticals and perishable food, cold chain traceability is more critical, while general manufacturing benefits more from comprehensive quality control processes.

Connection

Cold chain traceability ensures real-time monitoring of temperature-sensitive products during transportation, directly impacting quality control by maintaining product integrity and preventing spoilage. Precise data collection and tracking enable rapid identification of deviations or breaches, facilitating timely corrective actions that uphold safety and compliance standards. Effective integration of traceability systems enhances quality assurance by minimizing risk and ensuring consistent product performance from origin to destination.

Key Terms

Inspection protocols

Inspection protocols in quality control emphasize standardized procedures to ensure product safety and compliance with regulatory standards in manufacturing environments. Cold chain traceability protocols focus on monitoring temperature-sensitive products through real-time data logging and secure documentation from production to delivery to maintain product integrity. Discover how integrating these inspection protocols enhances overall product reliability and consumer trust.

Temperature monitoring

Temperature monitoring plays a critical role in both quality control and cold chain traceability by ensuring products remain within safe thermal limits to prevent spoilage or degradation. Advanced temperature sensors and data loggers enable real-time tracking and documentation, enhancing compliance with industry standards such as ISO 22000 and HACCP. Discover how integrating temperature monitoring technologies can optimize your supply chain integrity and product quality.

Real-time data logging

Quality control in cold chain logistics requires real-time data logging to monitor temperature, humidity, and product integrity continuously. Cold chain traceability systems leverage IoT sensors and blockchain technology to provide timestamped, tamper-proof records that ensure compliance and reduce spoilage risks. Discover how integrating advanced data logging solutions enhances both quality control and traceability for optimal cold chain management.

Source and External Links

What is Quality Control (QC)? - Simplilearn.com - Quality control is the process of testing and measuring products or services to ensure they meet specified quality standards, involving inspection, testing, statistical process control, corrective action, training, and continuous improvement.

What is quality control (QC)? - TechTarget - Quality control refers to procedures ensuring that a product or service adheres to defined quality criteria by inspection, data collection, corrective action, and ongoing monitoring to maintain quality standards.

What Is Quality Control? Definition, Importance and Methods - Indeed - Quality control is a business process that sets testing standards, tests materials and production stages, corrects problems, collects data, and continuously monitors the product or service quality to meet predefined standards.

dowidth.com

dowidth.com