Nearshoring and reshoring are strategic economic practices aimed at optimizing manufacturing and supply chain operations by relocating production closer to primary markets. Nearshoring involves moving production to nearby countries to reduce costs and improve logistics efficiency, while reshoring brings manufacturing back to the company's home country to enhance control and quality. Explore the key benefits and challenges of nearshoring and reshoring to determine the best approach for your business.

Why it is important

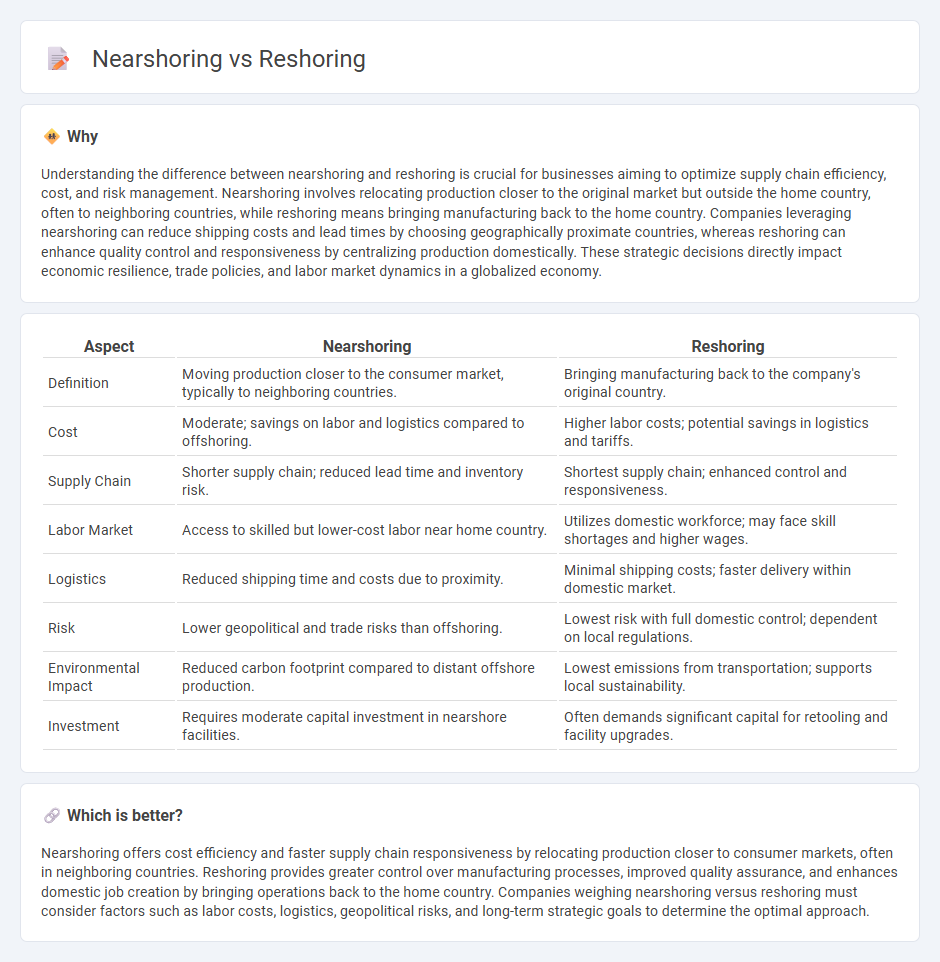

Understanding the difference between nearshoring and reshoring is crucial for businesses aiming to optimize supply chain efficiency, cost, and risk management. Nearshoring involves relocating production closer to the original market but outside the home country, often to neighboring countries, while reshoring means bringing manufacturing back to the home country. Companies leveraging nearshoring can reduce shipping costs and lead times by choosing geographically proximate countries, whereas reshoring can enhance quality control and responsiveness by centralizing production domestically. These strategic decisions directly impact economic resilience, trade policies, and labor market dynamics in a globalized economy.

Comparison Table

| Aspect | Nearshoring | Reshoring |

|---|---|---|

| Definition | Moving production closer to the consumer market, typically to neighboring countries. | Bringing manufacturing back to the company's original country. |

| Cost | Moderate; savings on labor and logistics compared to offshoring. | Higher labor costs; potential savings in logistics and tariffs. |

| Supply Chain | Shorter supply chain; reduced lead time and inventory risk. | Shortest supply chain; enhanced control and responsiveness. |

| Labor Market | Access to skilled but lower-cost labor near home country. | Utilizes domestic workforce; may face skill shortages and higher wages. |

| Logistics | Reduced shipping time and costs due to proximity. | Minimal shipping costs; faster delivery within domestic market. |

| Risk | Lower geopolitical and trade risks than offshoring. | Lowest risk with full domestic control; dependent on local regulations. |

| Environmental Impact | Reduced carbon footprint compared to distant offshore production. | Lowest emissions from transportation; supports local sustainability. |

| Investment | Requires moderate capital investment in nearshore facilities. | Often demands significant capital for retooling and facility upgrades. |

Which is better?

Nearshoring offers cost efficiency and faster supply chain responsiveness by relocating production closer to consumer markets, often in neighboring countries. Reshoring provides greater control over manufacturing processes, improved quality assurance, and enhances domestic job creation by bringing operations back to the home country. Companies weighing nearshoring versus reshoring must consider factors such as labor costs, logistics, geopolitical risks, and long-term strategic goals to determine the optimal approach.

Connection

Nearshoring and reshoring are interconnected strategies aimed at optimizing supply chains by relocating production closer to the home country to reduce costs, improve efficiency, and mitigate risks associated with long-distance manufacturing. Nearshoring focuses on moving operations to nearby countries with favorable trade agreements and lower labor costs, while reshoring involves bringing production back to the domestic market to enhance control and responsiveness. Both approaches respond to global economic shifts, supply chain disruptions, and rising labor expenses in distant offshore locations.

Key Terms

Supply Chain

Reshoring involves relocating manufacturing or supply chain operations back to the company's home country to enhance control, reduce lead times, and mitigate geopolitical risks. Nearshoring moves these operations closer to the home country, often in neighboring nations, to balance cost efficiency with improved supply chain responsiveness and reduced transportation expenses. Explore more insights on reshoring and nearshoring strategies to optimize your supply chain resilience and agility.

Labor Costs

Labor costs play a crucial role in the decision between reshoring and nearshoring, with reshoring typically involving higher wages due to relocation back to developed countries like the U.S. or Western Europe. Nearshoring offers a cost advantage by relocating production to nearby countries with lower labor expenses, such as Mexico or Eastern Europe, while maintaining proximity for easier supply chain management. Explore more insights on balancing labor costs with operational efficiency in global manufacturing strategies.

Trade Policy

Trade policy significantly influences decisions between reshoring and nearshoring by affecting tariffs, import/export regulations, and supply chain costs. Reshoring benefits from favorable domestic trade incentives and reduced dependency on foreign trade agreements, while nearshoring leverages regional trade alliances like USMCA to minimize customs barriers and transportation expenses. Explore more about trade policy impacts to optimize your supply chain strategy.

Source and External Links

Reshoring - SCRG - Provides an overview of reshoring, its benefits, challenges, and how companies can successfully bring manufacturing operations back to their home country.

What is Reshoring? Understanding Manufacturing Location Terms - Explains reshoring as the relocation of production back to the country where the company is headquartered or where their products are sold.

What is Reshoring? - Describes reshoring as the practice of bringing manufacturing and services back to the U.S. from overseas, benefiting the economy by creating jobs and reducing trade deficits.

dowidth.com

dowidth.com