Reshoring involves relocating manufacturing operations back to the company's home country to reduce supply chain risks and improve quality control. In-house production maintains complete operational oversight by keeping manufacturing internally, fostering innovation and ensuring proprietary processes remain confidential. Explore the economic impacts and strategic benefits of reshoring versus in-house production to make informed business decisions.

Why it is important

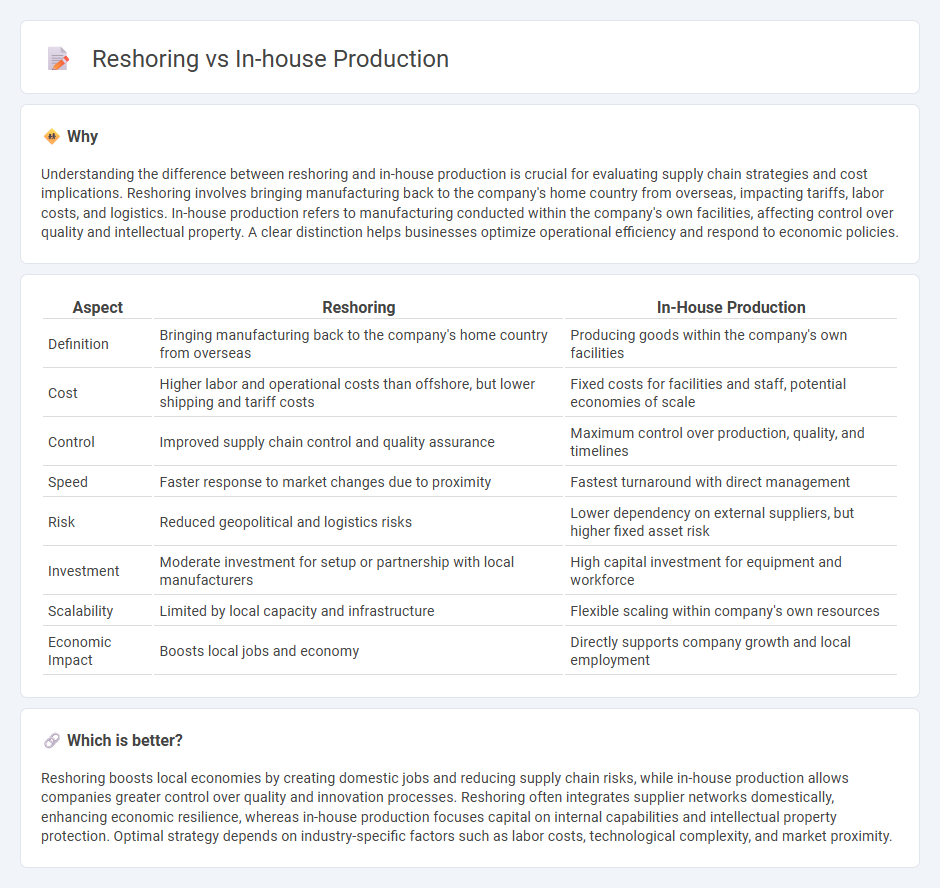

Understanding the difference between reshoring and in-house production is crucial for evaluating supply chain strategies and cost implications. Reshoring involves bringing manufacturing back to the company's home country from overseas, impacting tariffs, labor costs, and logistics. In-house production refers to manufacturing conducted within the company's own facilities, affecting control over quality and intellectual property. A clear distinction helps businesses optimize operational efficiency and respond to economic policies.

Comparison Table

| Aspect | Reshoring | In-House Production |

|---|---|---|

| Definition | Bringing manufacturing back to the company's home country from overseas | Producing goods within the company's own facilities |

| Cost | Higher labor and operational costs than offshore, but lower shipping and tariff costs | Fixed costs for facilities and staff, potential economies of scale |

| Control | Improved supply chain control and quality assurance | Maximum control over production, quality, and timelines |

| Speed | Faster response to market changes due to proximity | Fastest turnaround with direct management |

| Risk | Reduced geopolitical and logistics risks | Lower dependency on external suppliers, but higher fixed asset risk |

| Investment | Moderate investment for setup or partnership with local manufacturers | High capital investment for equipment and workforce |

| Scalability | Limited by local capacity and infrastructure | Flexible scaling within company's own resources |

| Economic Impact | Boosts local jobs and economy | Directly supports company growth and local employment |

Which is better?

Reshoring boosts local economies by creating domestic jobs and reducing supply chain risks, while in-house production allows companies greater control over quality and innovation processes. Reshoring often integrates supplier networks domestically, enhancing economic resilience, whereas in-house production focuses capital on internal capabilities and intellectual property protection. Optimal strategy depends on industry-specific factors such as labor costs, technological complexity, and market proximity.

Connection

Reshoring involves bringing manufacturing processes back to the company's home country to reduce dependency on foreign suppliers and improve supply chain resilience. In-house production supports reshoring by enabling companies to maintain direct control over quality, costs, and innovation while fostering local job creation. The synergy between reshoring and in-house production enhances economic stability and strengthens domestic industrial capabilities.

Key Terms

Supply Chain

In-house production enhances supply chain control by minimizing reliance on external suppliers, reducing lead times, and improving product quality consistency. Reshoring brings manufacturing closer to the end market, cutting transportation costs and mitigating risks such as tariffs and geopolitical disruptions. Explore comprehensive strategies to optimize supply chains through in-house production and reshoring.

Cost Efficiency

In-house production enables tighter cost control by eliminating outsourcing margins and reducing supply chain risks, often resulting in lower overall expenses. Reshoring brings manufacturing closer to demand centers, decreasing shipping costs and lead times while benefiting from local incentives and higher quality standards. Explore detailed comparisons to understand which strategy aligns best with your cost efficiency goals.

Domestic Manufacturing

Domestic manufacturing enhances supply chain resilience by reducing dependency on international suppliers and minimizing transportation costs. In-house production facilities improve quality control and enable faster response times to market demands, supporting innovation and customization. Explore the benefits of reshoring to optimize operational efficiency and strengthen local economies.

Source and External Links

Outsourcing vs In-House Manufacturing of Your Products - In-house production means a company manufactures goods using its own resources, allowing direct control over quality, faster response to market changes, and better protection of intellectual property.

In-house production - In-house production refers to bringing previously outsourced processes back under a company's own management, which can lead to cost savings, improved quality, and enhanced security, though not all processes can or should be brought in-house.

In-House Production vs Outsourced Solutions: Pros & Cons - In-house production is conducted by a company's own employees using existing assets, which generally results in better team communication, easier quality control, and lower employee turnover risk.

dowidth.com

dowidth.com