Resilient supply chains prioritize flexibility, risk management, and the ability to adapt quickly to disruptions, ensuring continuity even during global crises. Cost-optimized supply chains focus on minimizing expenses through lean operations, just-in-time inventory, and supplier cost efficiency, often at the expense of robustness. Explore the balance between resilience and cost efficiency to understand the future of global economic stability.

Why it is important

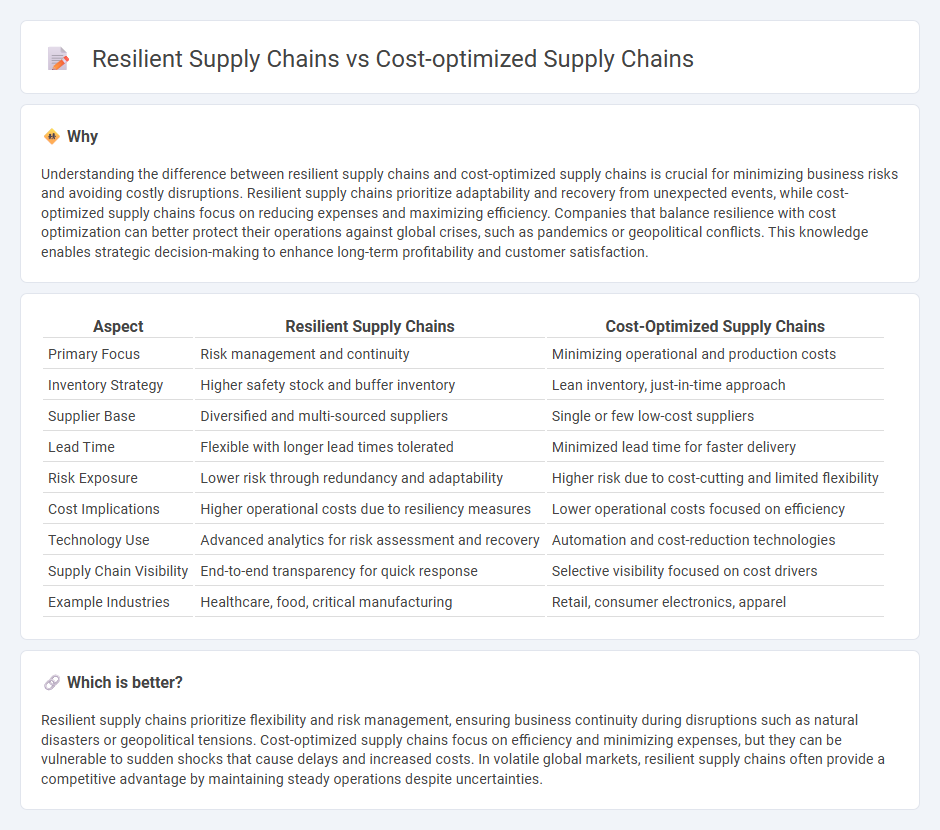

Understanding the difference between resilient supply chains and cost-optimized supply chains is crucial for minimizing business risks and avoiding costly disruptions. Resilient supply chains prioritize adaptability and recovery from unexpected events, while cost-optimized supply chains focus on reducing expenses and maximizing efficiency. Companies that balance resilience with cost optimization can better protect their operations against global crises, such as pandemics or geopolitical conflicts. This knowledge enables strategic decision-making to enhance long-term profitability and customer satisfaction.

Comparison Table

| Aspect | Resilient Supply Chains | Cost-Optimized Supply Chains |

|---|---|---|

| Primary Focus | Risk management and continuity | Minimizing operational and production costs |

| Inventory Strategy | Higher safety stock and buffer inventory | Lean inventory, just-in-time approach |

| Supplier Base | Diversified and multi-sourced suppliers | Single or few low-cost suppliers |

| Lead Time | Flexible with longer lead times tolerated | Minimized lead time for faster delivery |

| Risk Exposure | Lower risk through redundancy and adaptability | Higher risk due to cost-cutting and limited flexibility |

| Cost Implications | Higher operational costs due to resiliency measures | Lower operational costs focused on efficiency |

| Technology Use | Advanced analytics for risk assessment and recovery | Automation and cost-reduction technologies |

| Supply Chain Visibility | End-to-end transparency for quick response | Selective visibility focused on cost drivers |

| Example Industries | Healthcare, food, critical manufacturing | Retail, consumer electronics, apparel |

Which is better?

Resilient supply chains prioritize flexibility and risk management, ensuring business continuity during disruptions such as natural disasters or geopolitical tensions. Cost-optimized supply chains focus on efficiency and minimizing expenses, but they can be vulnerable to sudden shocks that cause delays and increased costs. In volatile global markets, resilient supply chains often provide a competitive advantage by maintaining steady operations despite uncertainties.

Connection

Resilient supply chains minimize disruptions by diversifying suppliers and incorporating flexibility, which reduces risks that can lead to costly delays and inventory shortages. Cost-optimized supply chains focus on efficiency and minimizing expenses, often through streamlined logistics and bulk purchasing, enhancing overall profitability. Integrating resilience into cost optimization balances risk mitigation with expense control, ensuring stable operations and sustained economic performance.

Key Terms

Efficiency

Cost-optimized supply chains prioritize minimizing expenses through lean inventory management, bulk purchasing, and streamlined logistics to achieve maximum efficiency. Resilient supply chains balance efficiency with flexibility by incorporating buffer stocks, diversifying suppliers, and investing in risk management to withstand disruptions. Explore detailed strategies to optimize both cost and resilience in supply chain operations.

Flexibility

Cost-optimized supply chains prioritize minimizing expenses through lean inventory and standardized processes, often sacrificing adaptability to market fluctuations. Resilient supply chains emphasize flexibility by maintaining buffer stocks, diversifying suppliers, and enabling rapid response to disruptions, ensuring continuous operations despite uncertainties. Explore in-depth strategies to balance cost efficiency with supply chain flexibility and resilience.

Risk Mitigation

Cost-optimized supply chains prioritize minimizing expenses through lean inventory and streamlined operations, often sacrificing flexibility and buffer capacity. Resilient supply chains emphasize risk mitigation by incorporating redundancies, diversified suppliers, and adaptable logistics to withstand disruptions. Explore how balancing cost efficiency with strategic risk management strengthens supply chain performance.

Source and External Links

What Drives the Economics of Supply Chain Cost Optimization - Supply chain cost optimization involves analyzing and refining processes to eliminate waste and improve resource utilization, focusing on demand and supply dynamics, economies of scale, and technology integration.

12 Ways to Reduce Supply Chain Costs - This article outlines strategies for reducing supply chain costs, including analyzing KPIs, optimizing shipping, and leveraging AI-based demand forecasting and predictive maintenance systems.

Mastering Supply Chain Cost Optimization - Supply chain cost optimization involves evaluating all supply chain functions to improve ROI while maintaining reliable supply, covering aspects like raw material sourcing, transportation, and inventory management.

dowidth.com

dowidth.com