Supply chain control towers centralize data integration and advanced analytics to proactively monitor, manage, and optimize supply chain operations in real-time. Supply chain visibility provides end-to-end transparency of inventory, shipments, and order status, enabling quicker responses to disruptions. Explore how these solutions enhance operational efficiency and decision-making in modern logistics.

Why it is important

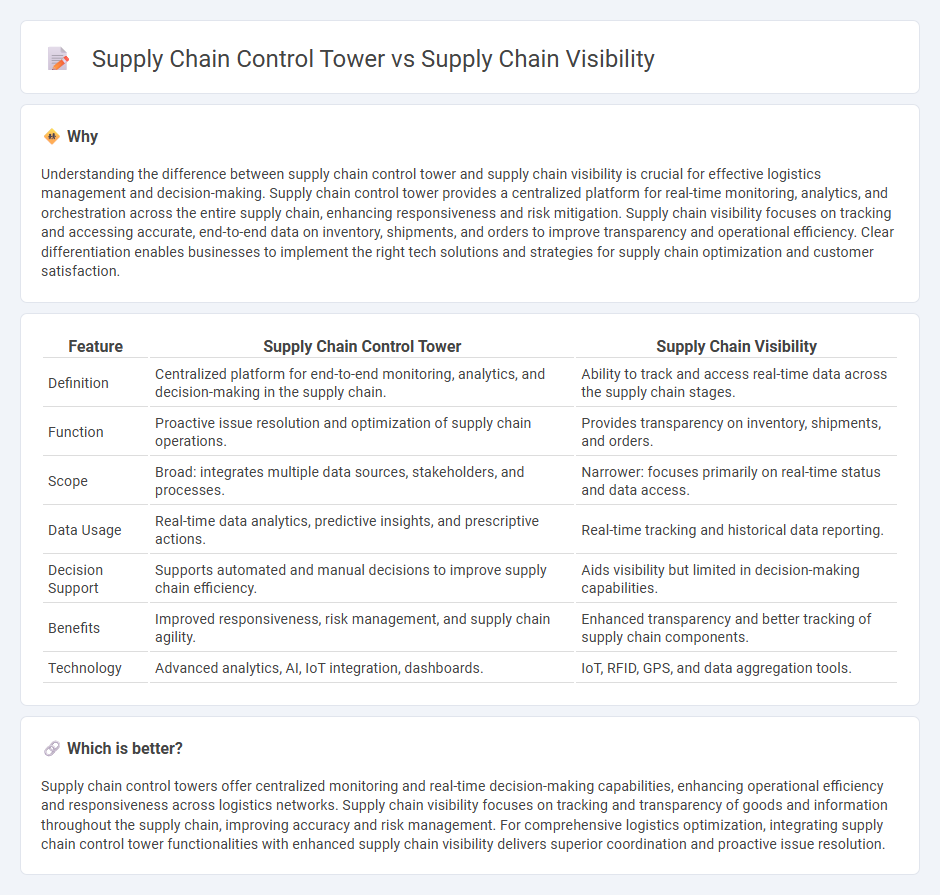

Understanding the difference between supply chain control tower and supply chain visibility is crucial for effective logistics management and decision-making. Supply chain control tower provides a centralized platform for real-time monitoring, analytics, and orchestration across the entire supply chain, enhancing responsiveness and risk mitigation. Supply chain visibility focuses on tracking and accessing accurate, end-to-end data on inventory, shipments, and orders to improve transparency and operational efficiency. Clear differentiation enables businesses to implement the right tech solutions and strategies for supply chain optimization and customer satisfaction.

Comparison Table

| Feature | Supply Chain Control Tower | Supply Chain Visibility |

|---|---|---|

| Definition | Centralized platform for end-to-end monitoring, analytics, and decision-making in the supply chain. | Ability to track and access real-time data across the supply chain stages. |

| Function | Proactive issue resolution and optimization of supply chain operations. | Provides transparency on inventory, shipments, and orders. |

| Scope | Broad: integrates multiple data sources, stakeholders, and processes. | Narrower: focuses primarily on real-time status and data access. |

| Data Usage | Real-time data analytics, predictive insights, and prescriptive actions. | Real-time tracking and historical data reporting. |

| Decision Support | Supports automated and manual decisions to improve supply chain efficiency. | Aids visibility but limited in decision-making capabilities. |

| Benefits | Improved responsiveness, risk management, and supply chain agility. | Enhanced transparency and better tracking of supply chain components. |

| Technology | Advanced analytics, AI, IoT integration, dashboards. | IoT, RFID, GPS, and data aggregation tools. |

Which is better?

Supply chain control towers offer centralized monitoring and real-time decision-making capabilities, enhancing operational efficiency and responsiveness across logistics networks. Supply chain visibility focuses on tracking and transparency of goods and information throughout the supply chain, improving accuracy and risk management. For comprehensive logistics optimization, integrating supply chain control tower functionalities with enhanced supply chain visibility delivers superior coordination and proactive issue resolution.

Connection

Supply chain control towers provide centralized monitoring and management of supply chain activities, enabling real-time data integration from multiple sources. This centralized system enhances supply chain visibility by offering comprehensive insights into inventory levels, transportation status, and supplier performance. Improved supply chain visibility through control towers facilitates proactive decision-making, risk mitigation, and efficient response to disruptions.

Key Terms

**Supply Chain Visibility:**

Supply Chain Visibility involves real-time tracking and transparency across the entire supply chain, enabling organizations to monitor inventory levels, shipments, and order statuses efficiently. Enhanced visibility supports proactive decision-making by identifying delays, risks, and opportunities for optimization promptly. Discover how leveraging Supply Chain Visibility can transform your operational efficiency and responsiveness.

Real-time Tracking

Supply chain visibility enables companies to monitor shipments, inventory levels, and order statuses across the entire supply chain in real time, improving transparency and responsiveness. A supply chain control tower builds upon visibility by offering centralized, data-driven decision-making capabilities, integrating real-time tracking data with advanced analytics to optimize operations proactively. Discover how leveraging both solutions can transform logistics efficiency and customer satisfaction.

Data Integration

Supply chain visibility provides real-time tracking of goods and inventory status across the entire supply chain, relying heavily on comprehensive data integration from multiple sources such as suppliers, logistics providers, and warehouses. Supply chain control towers utilize advanced data integration platforms to centralize, analyze, and orchestrate supply chain activities, enabling proactive decision-making and enhanced operational control. Explore the differences in data integration approaches between supply chain visibility and control towers to optimize your logistics management.

Source and External Links

What is Supply Chain Visibility? Meaning and Definition - GEP - Supply chain visibility is the ability to view or track inventory as it moves through the supply chain in real time, enabling enterprises to optimize inventory levels, improve coordination, mitigate risk, and make data-driven decisions for enhanced process efficiency.

What is Supply Chain Visibility? - Tibco - Supply chain visibility tracks products from raw materials to customers, providing transparency across all transactions and steps in the supply chain to reduce errors, improve efficiency, and enhance customer satisfaction.

What Is Supply Chain Visibility (SCV)? Definition & Examples - A highly visible supply chain integrates data not only from internal operations but also from suppliers' systems, allowing businesses to monitor components, track movement of goods, and quickly respond to issues throughout the entire supply chain journey.

dowidth.com

dowidth.com