Cold chain visibility involves real-time tracking and monitoring of temperature-sensitive products throughout the supply chain to ensure product integrity and compliance with regulatory standards. Cold chain security focuses on protecting these goods from theft, tampering, and contamination during transit and storage, employing technologies such as GPS tracking, tamper-evident seals, and secure packaging. Explore how integrating cold chain visibility and security can optimize refrigerated logistics and safeguard product quality.

Why it is important

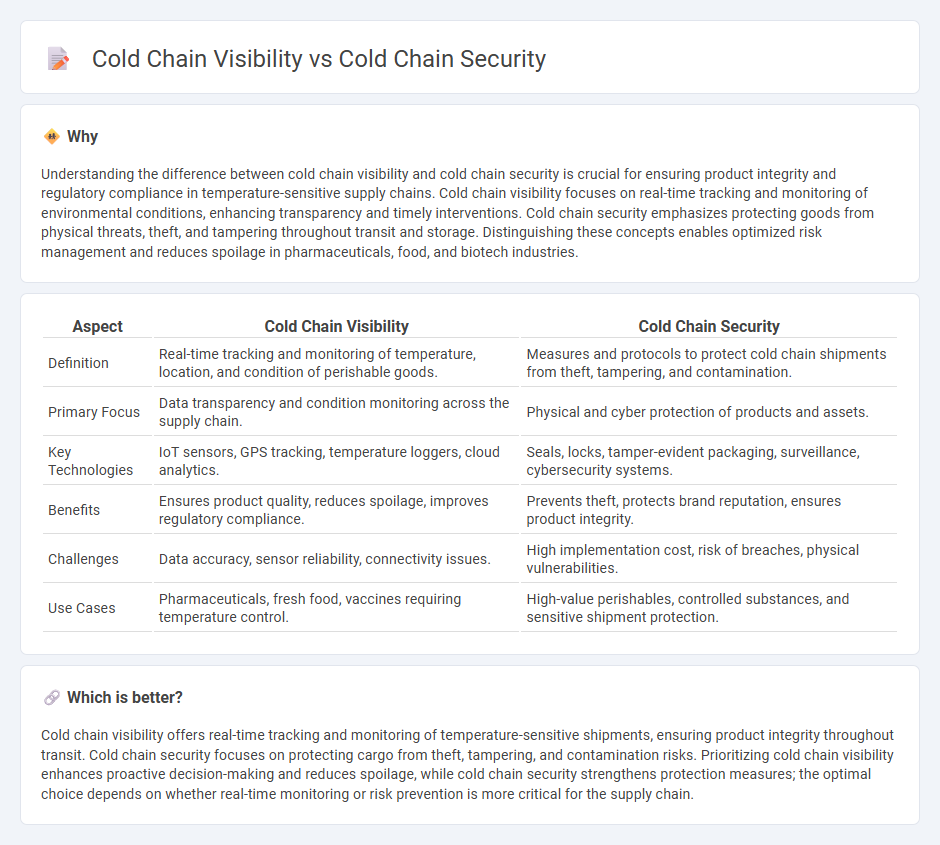

Understanding the difference between cold chain visibility and cold chain security is crucial for ensuring product integrity and regulatory compliance in temperature-sensitive supply chains. Cold chain visibility focuses on real-time tracking and monitoring of environmental conditions, enhancing transparency and timely interventions. Cold chain security emphasizes protecting goods from physical threats, theft, and tampering throughout transit and storage. Distinguishing these concepts enables optimized risk management and reduces spoilage in pharmaceuticals, food, and biotech industries.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Security |

|---|---|---|

| Definition | Real-time tracking and monitoring of temperature, location, and condition of perishable goods. | Measures and protocols to protect cold chain shipments from theft, tampering, and contamination. |

| Primary Focus | Data transparency and condition monitoring across the supply chain. | Physical and cyber protection of products and assets. |

| Key Technologies | IoT sensors, GPS tracking, temperature loggers, cloud analytics. | Seals, locks, tamper-evident packaging, surveillance, cybersecurity systems. |

| Benefits | Ensures product quality, reduces spoilage, improves regulatory compliance. | Prevents theft, protects brand reputation, ensures product integrity. |

| Challenges | Data accuracy, sensor reliability, connectivity issues. | High implementation cost, risk of breaches, physical vulnerabilities. |

| Use Cases | Pharmaceuticals, fresh food, vaccines requiring temperature control. | High-value perishables, controlled substances, and sensitive shipment protection. |

Which is better?

Cold chain visibility offers real-time tracking and monitoring of temperature-sensitive shipments, ensuring product integrity throughout transit. Cold chain security focuses on protecting cargo from theft, tampering, and contamination risks. Prioritizing cold chain visibility enhances proactive decision-making and reduces spoilage, while cold chain security strengthens protection measures; the optimal choice depends on whether real-time monitoring or risk prevention is more critical for the supply chain.

Connection

Cold chain visibility enhances the monitoring of temperature-sensitive products in transit, ensuring real-time data on environmental conditions and location. Cold chain security relies on this visibility to detect and prevent risks such as temperature excursions, tampering, or theft, maintaining product integrity. Together, they optimize supply chain reliability by ensuring compliance with regulatory standards and reducing spoilage or loss.

Key Terms

**Cold Chain Security:**

Cold chain security ensures the integrity and safety of temperature-sensitive products through robust monitoring, tamper-evident packaging, and real-time alerts to prevent contamination or spoilage. Technologies such as GPS tracking, biometric access controls, and blockchain authentication enhance protection against theft, unauthorized access, and temperature excursions. Explore advanced cold chain security solutions to safeguard your supply chain and maintain product quality.

Tamper-evident packaging

Cold chain security emphasizes protecting products from tampering, contamination, and theft throughout the transport and storage process, with tamper-evident packaging serving as a primary defense mechanism by providing clear indicators of unauthorized access. Cold chain visibility focuses on real-time monitoring and tracking, ensuring products remain within required temperature ranges and locations, but it may lack clear tampering signals. Discover how integrating tamper-evident packaging enhances both security and visibility in cold chain management.

Chain of custody

Cold chain security ensures the integrity and safety of temperature-sensitive products by preventing unauthorized access and tampering throughout the entire logistics process. Cold chain visibility provides real-time monitoring and tracking of environmental conditions, location, and handling status to maintain an unbroken chain of custody. Explore detailed insights on how enhancing cold chain security and visibility safeguards product quality and compliance.

Source and External Links

What is Cold Chain Management? - Cold chain management ensures the integrity, safety, and quality of temperature-sensitive products by controlling temperature, humidity, and storage conditions throughout transit, storage, and display, using advanced monitoring and packaging technologies.

Ensuring Cold Chain Integrity Across the Supply Chain - Maintaining cold chain security requires full monitoring, track-and-trace capabilities, and chain of custody documentation across all parties to prevent quality loss and combat counterfeit products in the supply network.

Proactive Security Strategies in Cold Chain Logistics | Indianapolis - Leading logistics providers now emphasize proactive security strategies--such as advanced certifications, risk management, and partnerships--to set new benchmarks and protect shipments from security lapses in the cold chain.

dowidth.com

dowidth.com