Containerization revolutionizes logistics by enabling standardized, efficient handling of cargo in large steel containers, significantly reducing loading times and minimizing damage. In contrast, break-bulk shipping involves individual, often irregularly sized goods loaded and unloaded piece by piece, increasing labor costs and transit times. Explore deeper insights into how containerization transforms global supply chains compared to traditional break-bulk methods.

Why it is important

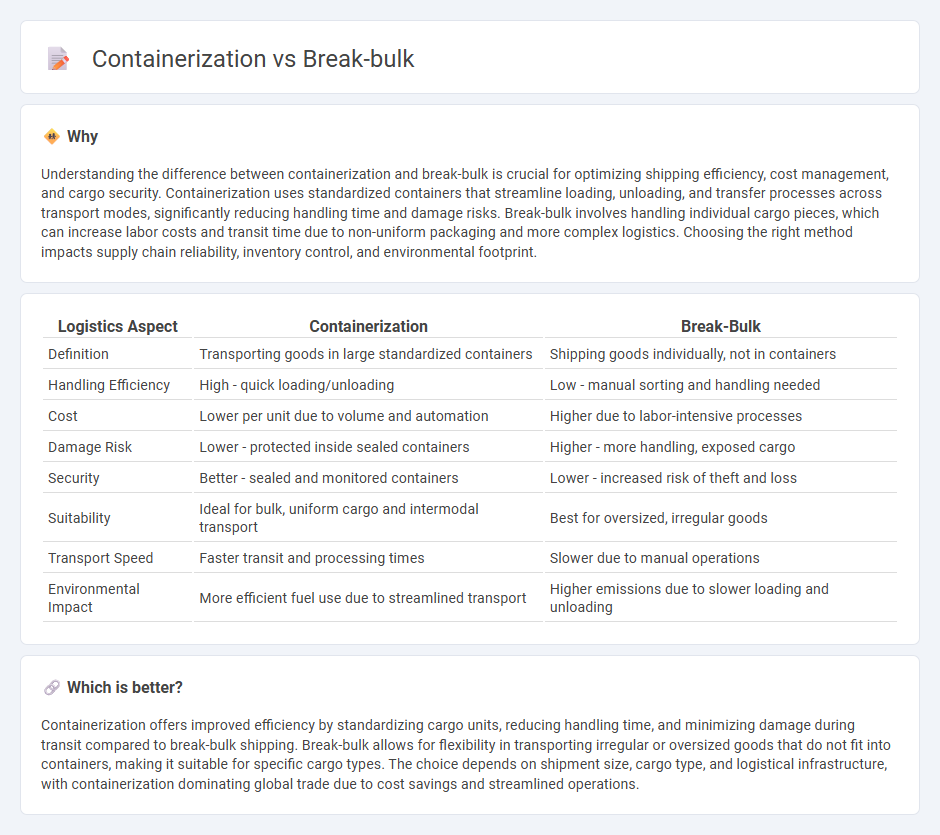

Understanding the difference between containerization and break-bulk is crucial for optimizing shipping efficiency, cost management, and cargo security. Containerization uses standardized containers that streamline loading, unloading, and transfer processes across transport modes, significantly reducing handling time and damage risks. Break-bulk involves handling individual cargo pieces, which can increase labor costs and transit time due to non-uniform packaging and more complex logistics. Choosing the right method impacts supply chain reliability, inventory control, and environmental footprint.

Comparison Table

| Logistics Aspect | Containerization | Break-Bulk |

|---|---|---|

| Definition | Transporting goods in large standardized containers | Shipping goods individually, not in containers |

| Handling Efficiency | High - quick loading/unloading | Low - manual sorting and handling needed |

| Cost | Lower per unit due to volume and automation | Higher due to labor-intensive processes |

| Damage Risk | Lower - protected inside sealed containers | Higher - more handling, exposed cargo |

| Security | Better - sealed and monitored containers | Lower - increased risk of theft and loss |

| Suitability | Ideal for bulk, uniform cargo and intermodal transport | Best for oversized, irregular goods |

| Transport Speed | Faster transit and processing times | Slower due to manual operations |

| Environmental Impact | More efficient fuel use due to streamlined transport | Higher emissions due to slower loading and unloading |

Which is better?

Containerization offers improved efficiency by standardizing cargo units, reducing handling time, and minimizing damage during transit compared to break-bulk shipping. Break-bulk allows for flexibility in transporting irregular or oversized goods that do not fit into containers, making it suitable for specific cargo types. The choice depends on shipment size, cargo type, and logistical infrastructure, with containerization dominating global trade due to cost savings and streamlined operations.

Connection

Containerization revolutionizes cargo transport by standardizing the size and handling of freight containers, while break-bulk refers to the traditional method of shipping goods in individual packages or units. Both methods aim to optimize cargo loading and unloading processes, but containerization enhances efficiency by reducing manual labor and minimizing damage risks compared to break-bulk. The transition from break-bulk to containerization has significantly accelerated global supply chains and reduced shipping costs.

Key Terms

Cargo Handling

Break-bulk cargo handling involves the manual loading and unloading of goods that are packaged individually, such as pallets, barrels, and crates, requiring more labor and time compared to containerization. Containerization streamlines cargo handling by using standardized containers, enabling faster loading, unloading, and improved protection from damage and theft. Explore our detailed comparison to understand which cargo handling method best suits your shipping needs.

Unitization

Break-bulk cargo involves handling goods individually, often leading to inefficient space utilization and increased labor costs, whereas containerization optimizes transportation through standardized units measuring 20 to 40 feet, enhancing security and reducing damage. Unitization in containerization bundles multiple items into a single container, streamlining loading, unloading, and inventory management while significantly lowering shipping costs. Explore our in-depth analysis to understand how unitization transforms global logistics efficiency.

Intermodal Transport

Break-bulk cargo involves handling goods individually or in smaller units, requiring multiple loading and unloading steps that increase handling time in intermodal transport. Containerization streamlines intermodal transport by using standardized containers, facilitating efficient transfers across ships, trucks, and trains while reducing cargo damage and transit delays. Explore the critical differences and benefits of break-bulk and containerization in optimizing intermodal transport systems.

Source and External Links

Breakbulk cargo - Breakbulk cargo involves transporting goods that are not containerized, often stowed and handled in unit loads like bags, crates, or drums.

What is Breakbulk? - Breakbulk shipping is used for transporting oversized or non-containerized items such as steel girders, construction equipment, and vehicles.

Difference between bulk and break bulk - Breakbulk cargo is transported in unitized forms like pallets, bags, or crates, distinguished from bulk cargo in handling and vessels used.

dowidth.com

dowidth.com