Freight visibility provides real-time tracking and status updates of shipments across transportation networks, enhancing supply chain transparency and efficiency. Cold chain monitoring focuses specifically on maintaining temperature-controlled environments for perishable goods, ensuring compliance with safety standards and reducing spoilage risks. Explore detailed insights into how freight visibility and cold chain monitoring optimize logistics operations and safeguard product integrity.

Why it is important

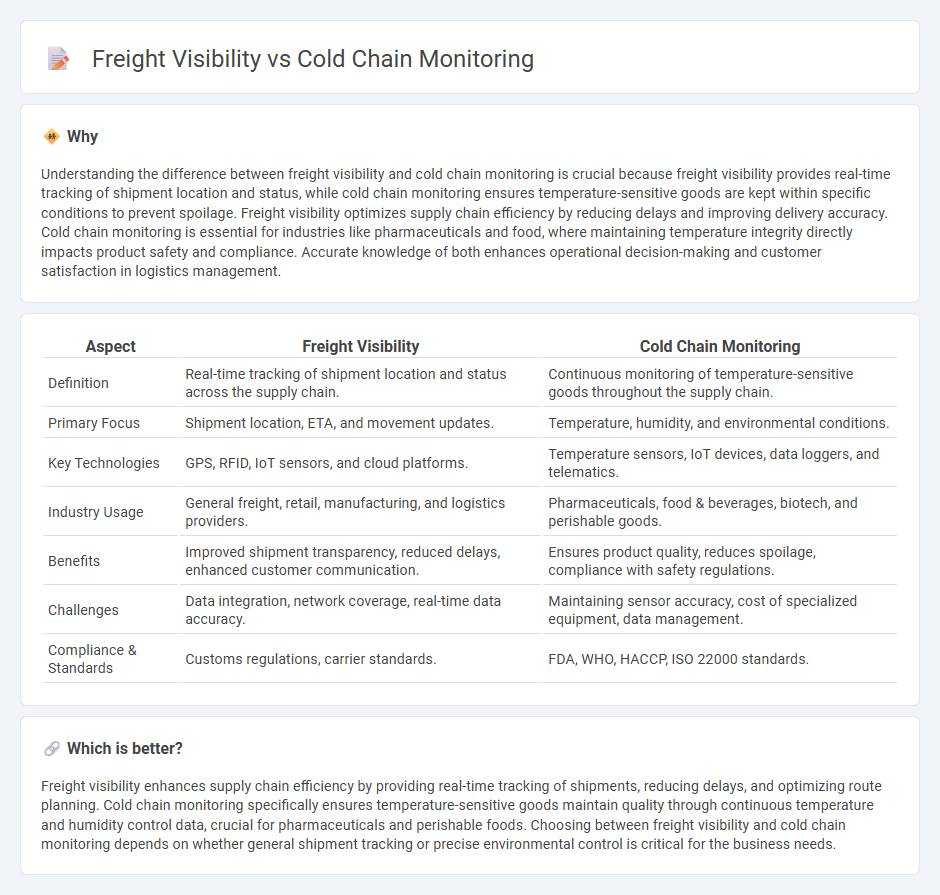

Understanding the difference between freight visibility and cold chain monitoring is crucial because freight visibility provides real-time tracking of shipment location and status, while cold chain monitoring ensures temperature-sensitive goods are kept within specific conditions to prevent spoilage. Freight visibility optimizes supply chain efficiency by reducing delays and improving delivery accuracy. Cold chain monitoring is essential for industries like pharmaceuticals and food, where maintaining temperature integrity directly impacts product safety and compliance. Accurate knowledge of both enhances operational decision-making and customer satisfaction in logistics management.

Comparison Table

| Aspect | Freight Visibility | Cold Chain Monitoring |

|---|---|---|

| Definition | Real-time tracking of shipment location and status across the supply chain. | Continuous monitoring of temperature-sensitive goods throughout the supply chain. |

| Primary Focus | Shipment location, ETA, and movement updates. | Temperature, humidity, and environmental conditions. |

| Key Technologies | GPS, RFID, IoT sensors, and cloud platforms. | Temperature sensors, IoT devices, data loggers, and telematics. |

| Industry Usage | General freight, retail, manufacturing, and logistics providers. | Pharmaceuticals, food & beverages, biotech, and perishable goods. |

| Benefits | Improved shipment transparency, reduced delays, enhanced customer communication. | Ensures product quality, reduces spoilage, compliance with safety regulations. |

| Challenges | Data integration, network coverage, real-time data accuracy. | Maintaining sensor accuracy, cost of specialized equipment, data management. |

| Compliance & Standards | Customs regulations, carrier standards. | FDA, WHO, HACCP, ISO 22000 standards. |

Which is better?

Freight visibility enhances supply chain efficiency by providing real-time tracking of shipments, reducing delays, and optimizing route planning. Cold chain monitoring specifically ensures temperature-sensitive goods maintain quality through continuous temperature and humidity control data, crucial for pharmaceuticals and perishable foods. Choosing between freight visibility and cold chain monitoring depends on whether general shipment tracking or precise environmental control is critical for the business needs.

Connection

Freight visibility technology enhances cold chain monitoring by providing real-time tracking of temperature-sensitive shipments, ensuring product integrity throughout transit. Sensors and IoT devices capture precise environmental data, enabling immediate alerts for deviations in temperature or humidity. This integration minimizes spoilage, improves regulatory compliance, and optimizes supply chain efficiency in perishable goods logistics.

Key Terms

**Cold Chain Monitoring:**

Cold chain monitoring ensures the precise control and real-time tracking of temperature-sensitive products throughout the logistics process, utilizing IoT sensors and advanced data analytics to prevent spoilage and maintain product integrity. Freight visibility, while broader, encompasses the overall tracking of shipments, including location and status updates, but lacks the specialized focus on environmental conditions critical for perishables. Explore how integrating cold chain monitoring enhances supply chain reliability and compliance with industry standards.

Temperature Sensors

Temperature sensors play a crucial role in cold chain monitoring by continuously tracking perishable goods' conditions to ensure compliance with safety standards and prevent spoilage. Freight visibility, while offering real-time location and status updates, integrates temperature sensor data to provide comprehensive insights into shipment integrity across transit routes. Explore how advanced temperature sensor technologies enhance both cold chain monitoring and freight visibility for optimized logistics management.

Data Loggers

Cold chain monitoring ensures the integrity of temperature-sensitive products by using data loggers to continuously record environmental conditions during transit. Freight visibility provides real-time tracking of shipments but lacks detailed temperature and humidity data critical for perishable goods. Explore how integrating data loggers enhances cold chain monitoring for superior freight management.

Source and External Links

What Is Cold Chain Monitoring? - Cold chain monitoring uses IoT sensors to track temperature and humidity in real-time during storage and transport of perishable goods, enabling quick corrective actions to prevent spoilage and ensure product quality.

What Is Cold Chain Monitoring? - It is the process of managing temperature and other environmental factors of sensitive products throughout the supply chain using wireless temperature data loggers that provide real-time alerts to avoid product degradation and waste.

The Ultimate Guide to Cold Chain Temperature Monitoring - Cold chain monitoring systematically maintains precise temperature controls through sensors that continuously record and transmit data, ensuring regulatory compliance and product integrity from origin to destination.

dowidth.com

dowidth.com