Pick to light systems use illuminated indicators at each picking location to guide workers quickly and accurately, enhancing order fulfillment speed and reducing errors. Pick to display systems employ digital screens to provide detailed picking instructions, offering flexibility for complex orders and easy updates. Explore how these systems optimize warehouse efficiency and order accuracy in various logistics environments.

Why it is important

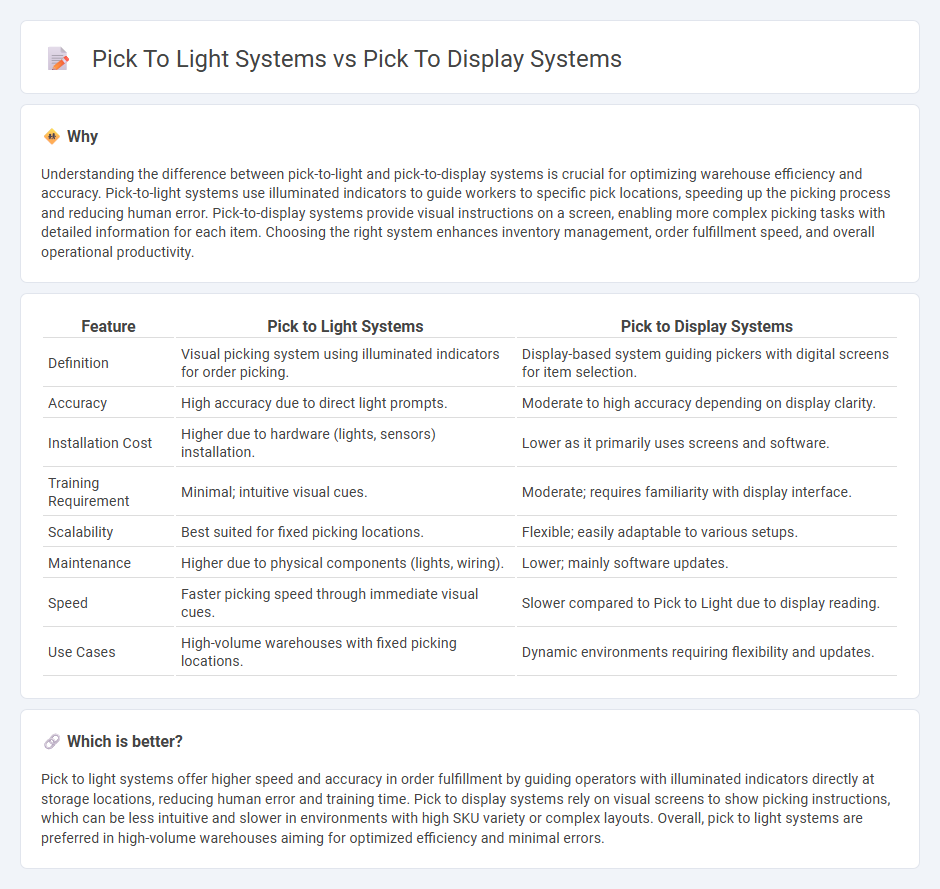

Understanding the difference between pick-to-light and pick-to-display systems is crucial for optimizing warehouse efficiency and accuracy. Pick-to-light systems use illuminated indicators to guide workers to specific pick locations, speeding up the picking process and reducing human error. Pick-to-display systems provide visual instructions on a screen, enabling more complex picking tasks with detailed information for each item. Choosing the right system enhances inventory management, order fulfillment speed, and overall operational productivity.

Comparison Table

| Feature | Pick to Light Systems | Pick to Display Systems |

|---|---|---|

| Definition | Visual picking system using illuminated indicators for order picking. | Display-based system guiding pickers with digital screens for item selection. |

| Accuracy | High accuracy due to direct light prompts. | Moderate to high accuracy depending on display clarity. |

| Installation Cost | Higher due to hardware (lights, sensors) installation. | Lower as it primarily uses screens and software. |

| Training Requirement | Minimal; intuitive visual cues. | Moderate; requires familiarity with display interface. |

| Scalability | Best suited for fixed picking locations. | Flexible; easily adaptable to various setups. |

| Maintenance | Higher due to physical components (lights, wiring). | Lower; mainly software updates. |

| Speed | Faster picking speed through immediate visual cues. | Slower compared to Pick to Light due to display reading. |

| Use Cases | High-volume warehouses with fixed picking locations. | Dynamic environments requiring flexibility and updates. |

Which is better?

Pick to light systems offer higher speed and accuracy in order fulfillment by guiding operators with illuminated indicators directly at storage locations, reducing human error and training time. Pick to display systems rely on visual screens to show picking instructions, which can be less intuitive and slower in environments with high SKU variety or complex layouts. Overall, pick to light systems are preferred in high-volume warehouses aiming for optimized efficiency and minimal errors.

Connection

Pick to light systems and pick to display systems are connected through their shared purpose of enhancing order fulfillment accuracy and efficiency in logistics operations. Pick to light systems use illuminated indicators to guide workers to specific product locations, while pick to display systems provide visual instructions on digital screens. Both technologies integrate with warehouse management systems (WMS) to streamline picking processes, reduce errors, and increase throughput in distribution centers.

Key Terms

Order Accuracy

Pick to display systems enhance order accuracy by providing clear visual instructions on a screen, reducing human errors through real-time guidance and highlighting correct items. Pick to light systems further improve precision by illuminating specific locations with LED indicators, enabling faster identification and confirmation of orders. Explore the detailed advantages of each system to optimize your warehouse order accuracy.

Picking Efficiency

Pick to display systems enhance picking efficiency by providing visual cues directly on the storage location, reducing errors and speeding up the process in moderately complex warehouses. Pick to light systems outperform them in high-volume operations through instant LED signals that guide pickers precisely, minimizing search time and increasing throughput. Explore our detailed comparison to determine the best picking solution tailored for your warehouse needs.

Technology Integration

Pick to display systems utilize digital screens to guide operators in order picking tasks, providing visual instructions for efficient item retrieval within warehouses or distribution centers. Pick to light systems employ LED light indicators mounted on storage racks or bins, enabling real-time, hands-free order selection and reducing picking errors through intuitive, illuminated guidance. Explore the advantages and integration possibilities of these technologies to optimize your warehouse operations effectively.

Source and External Links

Pick to Light & Put to Light - Voodoo Robotics - Pick-to-Light systems use indicator lights on shelves or carts to guide warehouse pickers to specific SKUs and quantities, confirmed by a simple button press, often integrating with warehouse software for efficient order fulfillment.

What is a Pick-to-Light System? - This system uses illuminated displays and buttons at storage locations to direct pickers to the right items and quantities, confirming picks in real-time to enhance accuracy and speed in warehouses.

Pick To Light system: What is it and how does it work? - Pick To Light integrates LED indicators and numerical displays with warehouse management software to speed up picking in high-volume warehouses, guiding pickers to correct locations and quantities efficiently.

dowidth.com

dowidth.com