Green corridors focus on creating dedicated, environmentally friendly routes that minimize carbon emissions by optimizing transportation paths and consolidating shipments. Milk runs streamline supply chains by using scheduled, multiple-stop delivery routes to reduce transportation costs and improve efficiency through repeated pickups and drop-offs. Explore the differences between green corridors and milk run strategies to enhance sustainable logistics solutions.

Why it is important

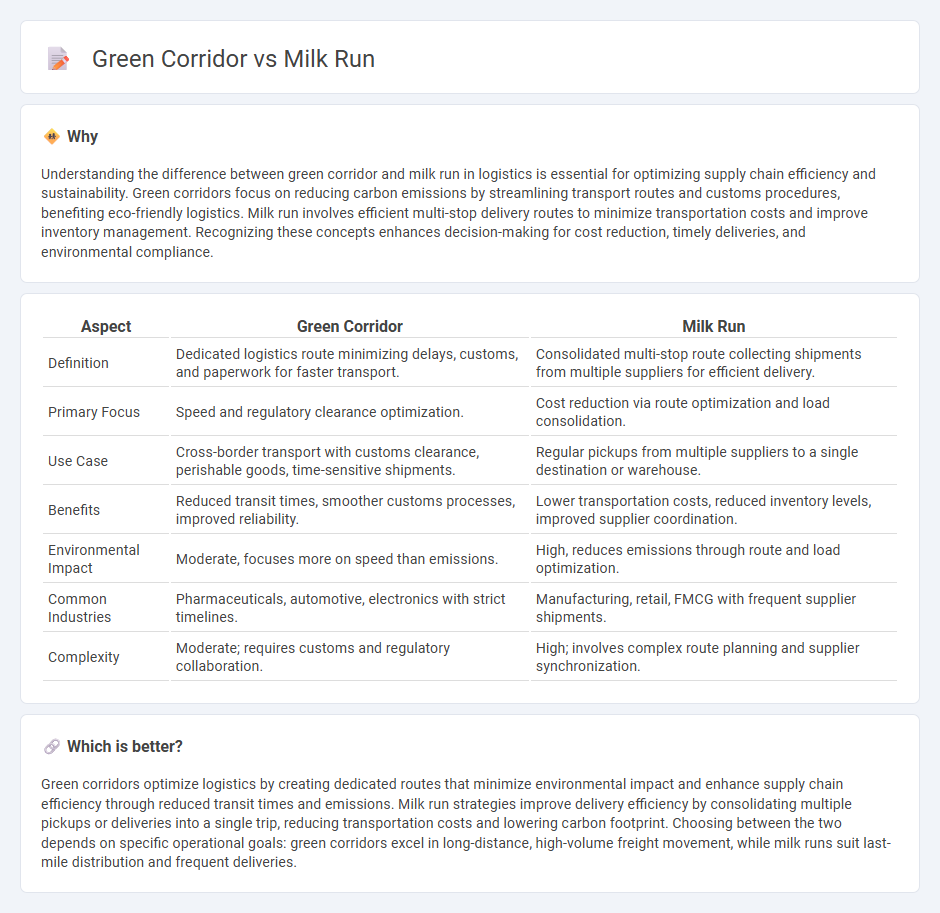

Understanding the difference between green corridor and milk run in logistics is essential for optimizing supply chain efficiency and sustainability. Green corridors focus on reducing carbon emissions by streamlining transport routes and customs procedures, benefiting eco-friendly logistics. Milk run involves efficient multi-stop delivery routes to minimize transportation costs and improve inventory management. Recognizing these concepts enhances decision-making for cost reduction, timely deliveries, and environmental compliance.

Comparison Table

| Aspect | Green Corridor | Milk Run |

|---|---|---|

| Definition | Dedicated logistics route minimizing delays, customs, and paperwork for faster transport. | Consolidated multi-stop route collecting shipments from multiple suppliers for efficient delivery. |

| Primary Focus | Speed and regulatory clearance optimization. | Cost reduction via route optimization and load consolidation. |

| Use Case | Cross-border transport with customs clearance, perishable goods, time-sensitive shipments. | Regular pickups from multiple suppliers to a single destination or warehouse. |

| Benefits | Reduced transit times, smoother customs processes, improved reliability. | Lower transportation costs, reduced inventory levels, improved supplier coordination. |

| Environmental Impact | Moderate, focuses more on speed than emissions. | High, reduces emissions through route and load optimization. |

| Common Industries | Pharmaceuticals, automotive, electronics with strict timelines. | Manufacturing, retail, FMCG with frequent supplier shipments. |

| Complexity | Moderate; requires customs and regulatory collaboration. | High; involves complex route planning and supplier synchronization. |

Which is better?

Green corridors optimize logistics by creating dedicated routes that minimize environmental impact and enhance supply chain efficiency through reduced transit times and emissions. Milk run strategies improve delivery efficiency by consolidating multiple pickups or deliveries into a single trip, reducing transportation costs and lowering carbon footprint. Choosing between the two depends on specific operational goals: green corridors excel in long-distance, high-volume freight movement, while milk runs suit last-mile distribution and frequent deliveries.

Connection

Green corridors reduce carbon emissions by optimizing transportation routes, while milk run logistics consolidates multiple deliveries to minimize vehicle trips. Both strategies enhance supply chain efficiency and sustainability by lowering fuel consumption and environmental impact. Implementing green corridors supports milk run operations by providing cleaner, faster pathways for consolidated shipments.

Key Terms

Route Optimization

Milk run logistics involves a single vehicle collecting and delivering goods from multiple suppliers or customers on a fixed route, significantly reducing transportation costs and optimizing load efficiency. Green corridors prioritize environmentally friendly transport routes, integrating sustainable practices like reduced emissions and energy consumption while enhancing overall route efficiency. Explore the benefits of milk run and green corridor strategies to improve your supply chain's route optimization and sustainability.

Consolidation

Milk run logistics maximizes consolidation by collecting smaller shipments from multiple suppliers in a single trip, reducing transportation costs and enhancing efficiency. Green corridors emphasize sustainability while enabling smooth, streamlined movement of consolidated goods through prioritized routes with reduced emissions. Explore how leveraging consolidation in these strategies can optimize your supply chain performance.

Sustainability

Milk run logistics optimize transportation by consolidating deliveries into a single route, reducing fuel consumption and emissions through efficient load management. Green corridors prioritize eco-friendly transport routes using cleaner energy sources and infrastructure designed to minimize environmental impact. Explore detailed strategies and benefits of integrating milk run systems with green corridor planning to enhance sustainability in supply chains.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - ShipBob - Milk run is a logistics approach where one vehicle picks up goods from multiple suppliers and delivers them together to one location, originating from milk delivery routes that collected milk from farms to a processor to keep supply fresh and prevent overstocking.

What is a milk run in logistics? | Red Stag Fulfillment - In logistics, a milk run is a pre-defined, recurring route for picking up and dropping off goods at multiple points, optimizing inventory flow and minimizing costly partial loads, similar to the historic milk delivery routes.

What is Milk Run in Logistics? - FlexQube - Milk run logistics enables frequent deliveries to multiple assembly areas within a facility to avoid overstocking and downtime by optimizing material transport routes and timing, inspired by dairy industry milk collections.

dowidth.com

dowidth.com