Pick to light systems enhance warehouse efficiency by using illuminated displays to guide operators to the correct picking locations, minimizing errors and speeding up order fulfillment. RF scanning systems rely on handheld barcode scanners to verify items and locations, providing flexibility but requiring more manual interaction. Discover how these technologies can transform your logistics operations for improved accuracy and productivity.

Why it is important

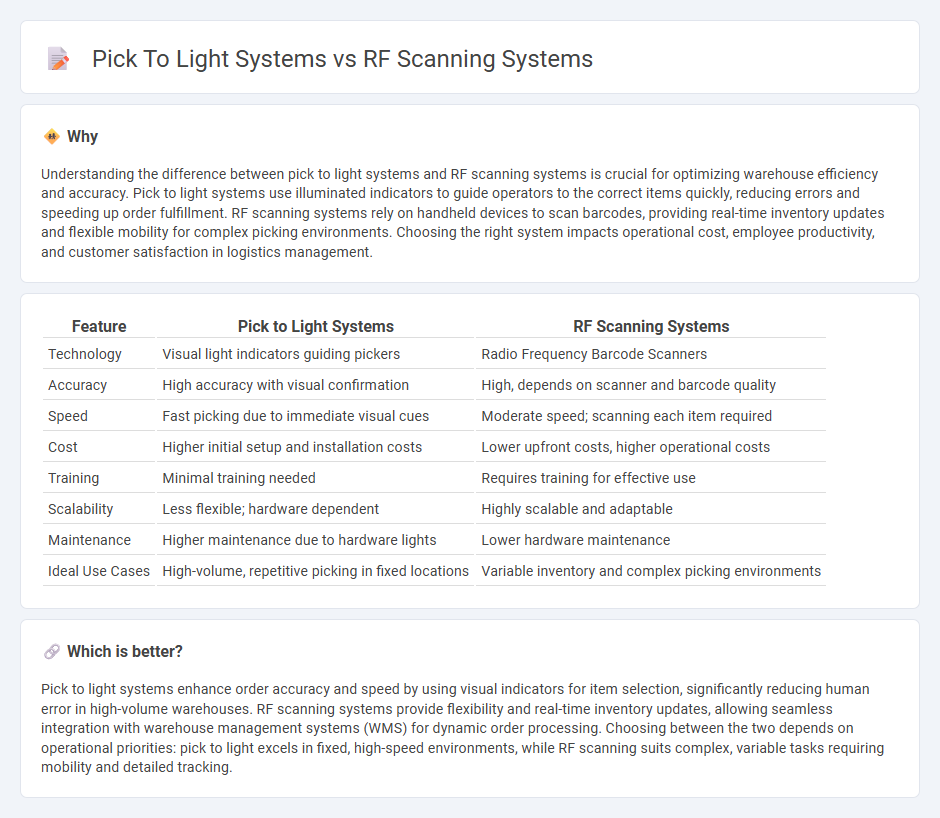

Understanding the difference between pick to light systems and RF scanning systems is crucial for optimizing warehouse efficiency and accuracy. Pick to light systems use illuminated indicators to guide operators to the correct items quickly, reducing errors and speeding up order fulfillment. RF scanning systems rely on handheld devices to scan barcodes, providing real-time inventory updates and flexible mobility for complex picking environments. Choosing the right system impacts operational cost, employee productivity, and customer satisfaction in logistics management.

Comparison Table

| Feature | Pick to Light Systems | RF Scanning Systems |

|---|---|---|

| Technology | Visual light indicators guiding pickers | Radio Frequency Barcode Scanners |

| Accuracy | High accuracy with visual confirmation | High, depends on scanner and barcode quality |

| Speed | Fast picking due to immediate visual cues | Moderate speed; scanning each item required |

| Cost | Higher initial setup and installation costs | Lower upfront costs, higher operational costs |

| Training | Minimal training needed | Requires training for effective use |

| Scalability | Less flexible; hardware dependent | Highly scalable and adaptable |

| Maintenance | Higher maintenance due to hardware lights | Lower hardware maintenance |

| Ideal Use Cases | High-volume, repetitive picking in fixed locations | Variable inventory and complex picking environments |

Which is better?

Pick to light systems enhance order accuracy and speed by using visual indicators for item selection, significantly reducing human error in high-volume warehouses. RF scanning systems provide flexibility and real-time inventory updates, allowing seamless integration with warehouse management systems (WMS) for dynamic order processing. Choosing between the two depends on operational priorities: pick to light excels in fixed, high-speed environments, while RF scanning suits complex, variable tasks requiring mobility and detailed tracking.

Connection

Pick to light systems and RF scanning systems are integrated through real-time data exchange that optimizes warehouse picking accuracy and speed. RF scanning devices capture barcode or RFID information, which updates the inventory system and triggers the corresponding pick to light indicators. This synchronization minimizes errors and streamlines order fulfillment by ensuring pickers receive precise, immediate visual instructions.

Key Terms

Barcode scanning

RF scanning systems leverage radio frequency technology to capture barcode data, enabling fast and accurate inventory tracking in warehouses. Pick to light systems use illuminated displays to guide operators to specific pick locations, enhancing picking efficiency but relying on manual barcode scanning for verification. Explore how integrating these technologies optimizes warehouse operations and enhances inventory accuracy.

Light-directed picking

Light-directed picking systems use visual indicators such as LED lights to guide operators directly to the correct items in a warehouse, increasing order accuracy and reducing picking time. RF scanning systems rely on handheld devices that scan barcodes for item identification, which can be slower and more prone to human error during navigation. Explore the benefits of light-directed picking to enhance warehouse efficiency and accuracy.

Real-time inventory tracking

RF scanning systems enable real-time inventory tracking by using radio frequency signals to instantly update stock levels as items are scanned, enhancing accuracy and minimizing discrepancies. Pick to light systems streamline order fulfillment through visual indicators, reducing errors but relying on manual scanning for inventory updates, which can delay real-time data synchronization. Discover how integrating these technologies can optimize your inventory management efficiency and accuracy.

Source and External Links

How RF Scanners Are Revolutionizing Modern Warehouses - RF scanning systems consist of handheld, fixed-mount, or wearable scanners that read barcodes or RFID tags, using a wireless network to transmit data to a central database or warehouse management system, with middleware facilitating communication between devices and software.

What Are RF Scanners? A Comprehensive Guide - Triton Store - RF scanners use radio waves to read data from tags or labels and come in types such as laser RF scanners, which read barcodes via laser reflection, and fixed-mount RF scanners, which are stationary devices used in high-volume automated environments.

RF Scanning: A Comprehensive Guide for Warehousing - Propel Apps - RF scanning technology captures data from barcodes or RFID tags via radio frequency and is essential in inventory and logistics management for real-time tracking, improving accuracy, reducing errors, and streamlining supply chain operations.

dowidth.com

dowidth.com