Pop-up warehousing offers flexible, short-term storage solutions near demand hotspots, reducing last-mile delivery times and costs. Cross-docking streamlines logistics by transferring goods directly from inbound to outbound transportation, minimizing inventory holding and enhancing supply chain efficiency. Explore how these strategies can optimize your logistics operations and meet evolving market demands.

Why it is important

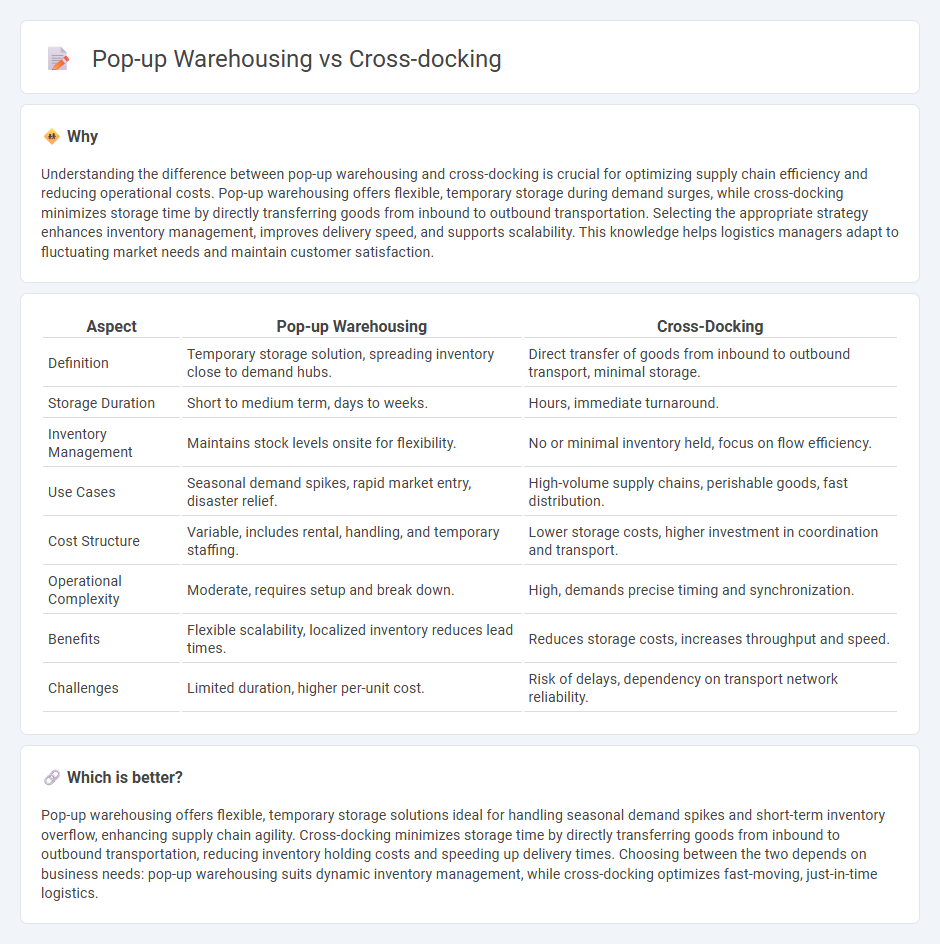

Understanding the difference between pop-up warehousing and cross-docking is crucial for optimizing supply chain efficiency and reducing operational costs. Pop-up warehousing offers flexible, temporary storage during demand surges, while cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation. Selecting the appropriate strategy enhances inventory management, improves delivery speed, and supports scalability. This knowledge helps logistics managers adapt to fluctuating market needs and maintain customer satisfaction.

Comparison Table

| Aspect | Pop-up Warehousing | Cross-Docking |

|---|---|---|

| Definition | Temporary storage solution, spreading inventory close to demand hubs. | Direct transfer of goods from inbound to outbound transport, minimal storage. |

| Storage Duration | Short to medium term, days to weeks. | Hours, immediate turnaround. |

| Inventory Management | Maintains stock levels onsite for flexibility. | No or minimal inventory held, focus on flow efficiency. |

| Use Cases | Seasonal demand spikes, rapid market entry, disaster relief. | High-volume supply chains, perishable goods, fast distribution. |

| Cost Structure | Variable, includes rental, handling, and temporary staffing. | Lower storage costs, higher investment in coordination and transport. |

| Operational Complexity | Moderate, requires setup and break down. | High, demands precise timing and synchronization. |

| Benefits | Flexible scalability, localized inventory reduces lead times. | Reduces storage costs, increases throughput and speed. |

| Challenges | Limited duration, higher per-unit cost. | Risk of delays, dependency on transport network reliability. |

Which is better?

Pop-up warehousing offers flexible, temporary storage solutions ideal for handling seasonal demand spikes and short-term inventory overflow, enhancing supply chain agility. Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transportation, reducing inventory holding costs and speeding up delivery times. Choosing between the two depends on business needs: pop-up warehousing suits dynamic inventory management, while cross-docking optimizes fast-moving, just-in-time logistics.

Connection

Pop-up warehousing and cross-docking both enhance supply chain agility by minimizing storage time and accelerating product flow. Pop-up warehousing provides temporary, flexible storage solutions near demand centers, while cross-docking streamlines inventory movement by directly transferring goods from inbound to outbound transportation. Integrating these strategies reduces lead times, lowers logistics costs, and improves responsiveness to market fluctuations.

Key Terms

Inventory Flow

Cross-docking streamlines inventory flow by transferring goods directly from inbound to outbound transportation with minimal storage time, reducing handling and accelerating order fulfillment. Pop-up warehousing temporarily increases storage capacity by utilizing flexible, short-term warehouse space to manage inventory surges or seasonal demand without long-term commitments. Explore the advantages and operational fit of cross-docking and pop-up warehousing to optimize your supply chain efficiency.

Transit Time

Cross-docking minimizes transit time by transferring goods directly from inbound to outbound transportation without long storage, enhancing supply chain speed. Pop-up warehousing offers flexible, temporary storage near demand centers, reducing last-mile delivery times but involves additional handling. Explore how transit time impacts your logistics efficiency by learning more about these strategies.

Storage Duration

Cross-docking minimizes storage duration by transferring goods directly from inbound to outbound transportation, often within hours, reducing or eliminating warehousing needs. Pop-up warehousing extends storage duration temporarily, providing flexible space during peak demand periods or special events to manage inventory overflow. Explore the advantages of each strategy to optimize your supply chain efficiency and storage solutions.

Source and External Links

Cross Docking: Definition, History, and Process - Inbound Logistics - Cross docking is a shipping method transferring goods with minimal storage by moving items directly from inbound to outbound transportation, using methods like continuous cross docking, consolidation, and de-consolidation to enhance efficiency and reduce handling time.

What Is Cross-Docking? Definition, Types & Advantages - NetSuite - Cross-docking is a supply chain strategy that accelerates delivery and reduces costs by transferring goods directly from inbound to outbound vehicles at a logistics facility, minimizing warehouse storage and improving inventory control.

Understanding cross-docking: A comprehensive guide - Maersk - Cross-docking is a logistics process that minimizes storage by directly transferring products to customers or next destinations, with types including pre-distribution, post-distribution, continuous, consolidation, and deconsolidation, tailored to various industries like retail, manufacturing, and e-commerce.

dowidth.com

dowidth.com