Milk run logistics streamlines supply chains by consolidating multiple pickups or deliveries into a single, efficient route, reducing transportation costs and minimizing inventory levels. Just-in-time (JIT) delivery focuses on synchronizing production schedules with demand to ensure materials arrive exactly when needed, eliminating excess stock and enhancing cash flow. Explore deeper into how these logistics strategies optimize operational efficiency and cost savings.

Why it is important

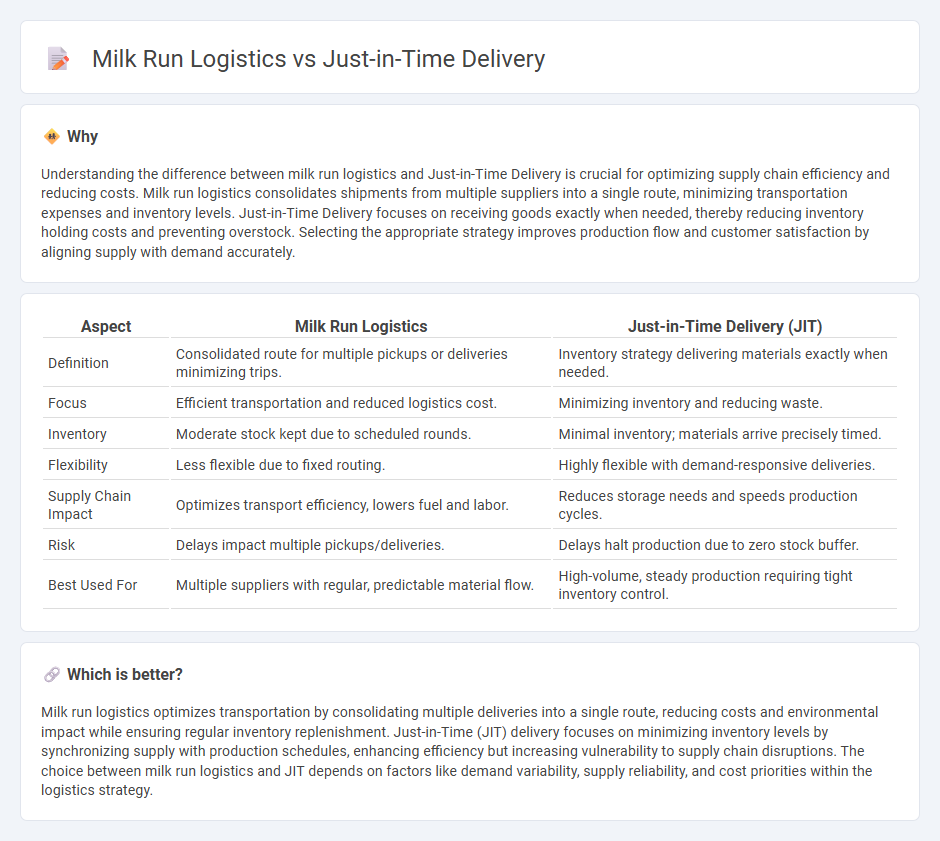

Understanding the difference between milk run logistics and Just-in-Time Delivery is crucial for optimizing supply chain efficiency and reducing costs. Milk run logistics consolidates shipments from multiple suppliers into a single route, minimizing transportation expenses and inventory levels. Just-in-Time Delivery focuses on receiving goods exactly when needed, thereby reducing inventory holding costs and preventing overstock. Selecting the appropriate strategy improves production flow and customer satisfaction by aligning supply with demand accurately.

Comparison Table

| Aspect | Milk Run Logistics | Just-in-Time Delivery (JIT) |

|---|---|---|

| Definition | Consolidated route for multiple pickups or deliveries minimizing trips. | Inventory strategy delivering materials exactly when needed. |

| Focus | Efficient transportation and reduced logistics cost. | Minimizing inventory and reducing waste. |

| Inventory | Moderate stock kept due to scheduled rounds. | Minimal inventory; materials arrive precisely timed. |

| Flexibility | Less flexible due to fixed routing. | Highly flexible with demand-responsive deliveries. |

| Supply Chain Impact | Optimizes transport efficiency, lowers fuel and labor. | Reduces storage needs and speeds production cycles. |

| Risk | Delays impact multiple pickups/deliveries. | Delays halt production due to zero stock buffer. |

| Best Used For | Multiple suppliers with regular, predictable material flow. | High-volume, steady production requiring tight inventory control. |

Which is better?

Milk run logistics optimizes transportation by consolidating multiple deliveries into a single route, reducing costs and environmental impact while ensuring regular inventory replenishment. Just-in-Time (JIT) delivery focuses on minimizing inventory levels by synchronizing supply with production schedules, enhancing efficiency but increasing vulnerability to supply chain disruptions. The choice between milk run logistics and JIT depends on factors like demand variability, supply reliability, and cost priorities within the logistics strategy.

Connection

Milk run logistics streamlines supply chain processes by consolidating multiple pickups or deliveries into a single, efficient route, minimizing transportation costs and inventory levels. Just-in-Time (JIT) Delivery relies on this continuous, timely flow of materials to reduce waste and inventory holding costs by receiving goods exactly when needed in production. The integration of milk run logistics with JIT delivery enhances operational efficiency through synchronized scheduling and reduced lead times, ensuring smooth production cycles and inventory optimization.

Key Terms

Inventory Reduction

Just-in-Time (JIT) delivery minimizes inventory by synchronizing production schedules with supplier shipments, reducing stock holding costs and enhancing cash flow. Milk run logistics optimize inventory reduction through consolidated transportation routes that ensure frequent, smaller deliveries, reducing excess stock and minimizing storage space. Explore detailed strategies to optimize inventory reduction by integrating JIT and milk run logistics.

Route Optimization

Just-in-Time Delivery maximizes efficiency by synchronizing inventory arrival with production schedules, minimizing storage costs through precise timing. Milk run logistics enhances route optimization by consolidating shipments from multiple suppliers into a single, consistent delivery loop, reducing transportation costs and environmental impact. Explore detailed strategies to optimize your supply chain routes and improve overall logistics performance.

Lead Time

Just-in-Time (JIT) delivery minimizes lead time by synchronizing inventory arrivals precisely with production schedules, reducing storage costs and ensuring a swift response to demand fluctuations. Milk run logistics optimizes lead time through consolidated shipments from multiple suppliers, balancing frequency and load size to maintain consistent supply while cutting transportation expenses. Explore detailed comparisons to enhance supply chain efficiency by understanding how each method impacts lead time.

Source and External Links

Just In Time (JIT) Delivery: The Ultimate Guide - Elite EXTRA - Just-in-Time Delivery is an inventory and supply chain management approach that increases efficiency by producing and delivering products on demand to reduce inventory, minimizing storage costs and enabling quick response to customer demand.

What is JIT Delivery? - AGI Global Logistics - JIT Delivery is a logistics strategy aiming to minimize inventory storage costs and waste by ensuring goods arrive exactly when needed, employing pull-based production and lean manufacturing principles with tools like the Kanban system to optimize supply chains.

Just in Time Delivery: What is it, and How Does it Affect Supply ... - Just-in-Time Delivery involves completing production just in time to fulfill orders, keeping minimal inventory to satisfy demand immediately and is exemplified by industries like restaurants where products are prepared on order to maintain freshness and reduce waste.

dowidth.com

dowidth.com