Robotic process automation (RPA) in logistics streamlines repetitive tasks such as shipment tracking, order processing, and invoicing, enhancing operational efficiency and reducing human error. Inventory management software focuses on real-time stock monitoring, demand forecasting, and automated replenishment to optimize warehouse management and prevent stockouts. Explore how integrating RPA with inventory management software can revolutionize supply chain operations and improve overall productivity.

Why it is important

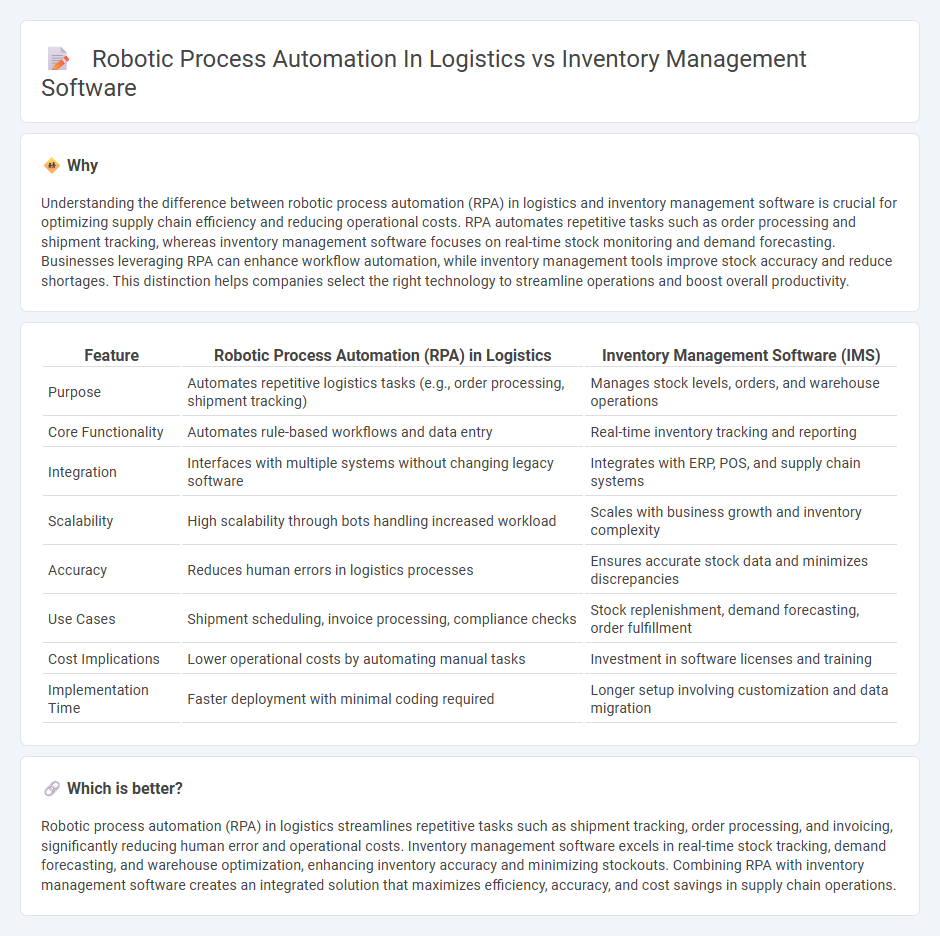

Understanding the difference between robotic process automation (RPA) in logistics and inventory management software is crucial for optimizing supply chain efficiency and reducing operational costs. RPA automates repetitive tasks such as order processing and shipment tracking, whereas inventory management software focuses on real-time stock monitoring and demand forecasting. Businesses leveraging RPA can enhance workflow automation, while inventory management tools improve stock accuracy and reduce shortages. This distinction helps companies select the right technology to streamline operations and boost overall productivity.

Comparison Table

| Feature | Robotic Process Automation (RPA) in Logistics | Inventory Management Software (IMS) |

|---|---|---|

| Purpose | Automates repetitive logistics tasks (e.g., order processing, shipment tracking) | Manages stock levels, orders, and warehouse operations |

| Core Functionality | Automates rule-based workflows and data entry | Real-time inventory tracking and reporting |

| Integration | Interfaces with multiple systems without changing legacy software | Integrates with ERP, POS, and supply chain systems |

| Scalability | High scalability through bots handling increased workload | Scales with business growth and inventory complexity |

| Accuracy | Reduces human errors in logistics processes | Ensures accurate stock data and minimizes discrepancies |

| Use Cases | Shipment scheduling, invoice processing, compliance checks | Stock replenishment, demand forecasting, order fulfillment |

| Cost Implications | Lower operational costs by automating manual tasks | Investment in software licenses and training |

| Implementation Time | Faster deployment with minimal coding required | Longer setup involving customization and data migration |

Which is better?

Robotic process automation (RPA) in logistics streamlines repetitive tasks such as shipment tracking, order processing, and invoicing, significantly reducing human error and operational costs. Inventory management software excels in real-time stock tracking, demand forecasting, and warehouse optimization, enhancing inventory accuracy and minimizing stockouts. Combining RPA with inventory management software creates an integrated solution that maximizes efficiency, accuracy, and cost savings in supply chain operations.

Connection

Robotic process automation (RPA) enhances logistics and inventory management software by streamlining repetitive tasks such as order processing, shipment tracking, and stock level updates, leading to increased accuracy and efficiency. Integration of RPA with inventory management systems enables real-time data synchronization, reducing manual errors and optimizing supply chain workflows. This synergy supports faster decision-making and improved resource allocation across logistics operations.

Key Terms

**Inventory Management Software:**

Inventory management software streamlines warehouse operations by providing real-time tracking, automated stock replenishment, and demand forecasting, reducing human errors and enhancing accuracy. Integration with ERP systems and IoT devices enables seamless data flow, optimizing supply chain visibility and operational efficiency. Explore how advanced inventory management solutions can transform logistics workflows and improve overall performance.

Stock Tracking

Inventory management software centralizes real-time stock tracking through automated data collection, enhancing accuracy and minimizing human error. Robotic Process Automation (RPA) improves logistics efficiency by automating repetitive tasks such as order processing and inventory updates, reducing processing time and operational costs. Explore how combining both technologies can streamline stock tracking and revolutionize supply chain management.

Reorder Point

Inventory management software optimizes reorder points by analyzing stock levels, demand patterns, and lead times to prevent stockouts or overstock situations efficiently. Robotic Process Automation (RPA) streamlines repetitive tasks such as data entry and order processing, enhancing accuracy and speed but relies on pre-set thresholds without advanced predictive analytics. Explore the specific advantages of each technology to determine the best reorder point strategy for your logistics operations.

Source and External Links

Zoho Inventory - Free inventory management software - Zoho Inventory is designed for small and growing businesses to manage inventory across multiple channels, offering features like sales tracking, centralized dashboard, vendor and purchase monitoring, warehouse control, item tracking with serial/batch numbers, and smart automation for reports and workflows.

inFlow Inventory Management Software - inFlow simplifies inventory management for small to mid-size businesses, providing easy-to-use tools for stock control, order tracking, sales, shipping, and barcode scanning, scalable from sole entrepreneurs to larger teams.

Sortly: Inventory Simplified - Sortly offers a versatile inventory software trusted by over 15,000 businesses, with mobile-friendly barcode and QR scanning, real-time reporting, cloud synchronization across devices, and alerts for low stock, suitable for audits and forecasting.

dowidth.com

dowidth.com