Milk run delivery optimizes logistics by consolidating multiple shipments into one route, reducing transportation costs and improving inventory management. Direct shipment sends goods straight from supplier to customer, ensuring faster delivery but potentially higher expenses and less flexibility. Explore the advantages and applications of each method to determine the best solution for your supply chain needs.

Why it is important

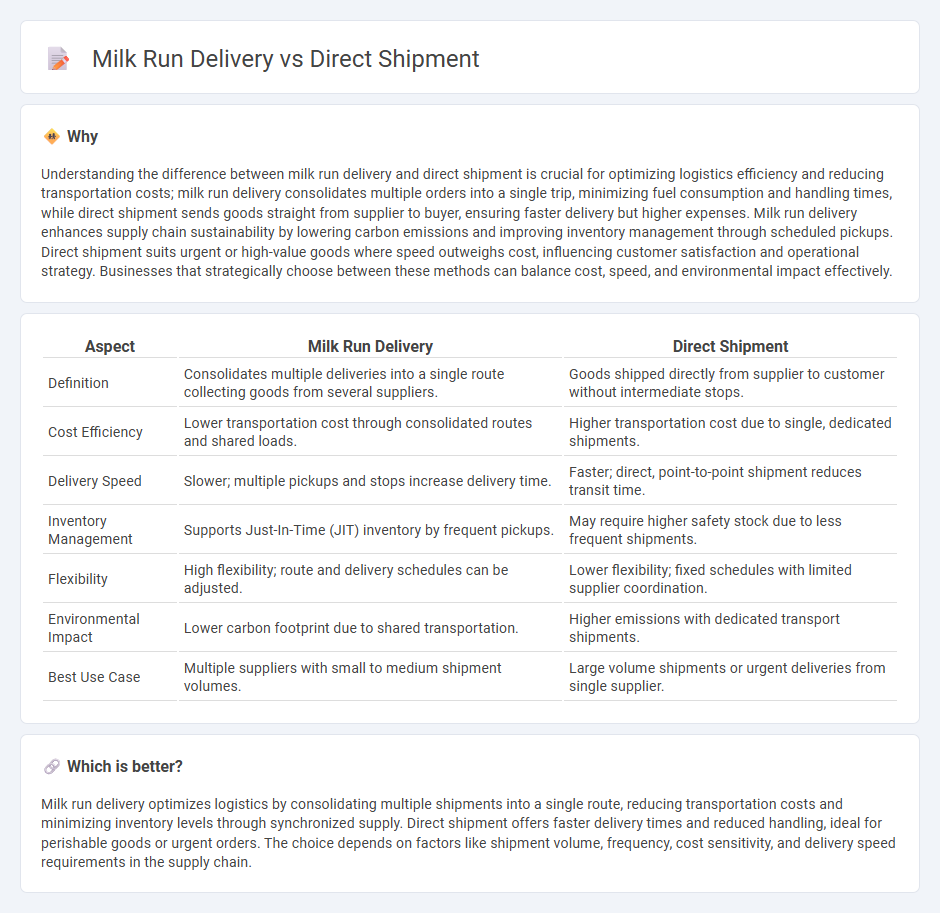

Understanding the difference between milk run delivery and direct shipment is crucial for optimizing logistics efficiency and reducing transportation costs; milk run delivery consolidates multiple orders into a single trip, minimizing fuel consumption and handling times, while direct shipment sends goods straight from supplier to buyer, ensuring faster delivery but higher expenses. Milk run delivery enhances supply chain sustainability by lowering carbon emissions and improving inventory management through scheduled pickups. Direct shipment suits urgent or high-value goods where speed outweighs cost, influencing customer satisfaction and operational strategy. Businesses that strategically choose between these methods can balance cost, speed, and environmental impact effectively.

Comparison Table

| Aspect | Milk Run Delivery | Direct Shipment |

|---|---|---|

| Definition | Consolidates multiple deliveries into a single route collecting goods from several suppliers. | Goods shipped directly from supplier to customer without intermediate stops. |

| Cost Efficiency | Lower transportation cost through consolidated routes and shared loads. | Higher transportation cost due to single, dedicated shipments. |

| Delivery Speed | Slower; multiple pickups and stops increase delivery time. | Faster; direct, point-to-point shipment reduces transit time. |

| Inventory Management | Supports Just-In-Time (JIT) inventory by frequent pickups. | May require higher safety stock due to less frequent shipments. |

| Flexibility | High flexibility; route and delivery schedules can be adjusted. | Lower flexibility; fixed schedules with limited supplier coordination. |

| Environmental Impact | Lower carbon footprint due to shared transportation. | Higher emissions with dedicated transport shipments. |

| Best Use Case | Multiple suppliers with small to medium shipment volumes. | Large volume shipments or urgent deliveries from single supplier. |

Which is better?

Milk run delivery optimizes logistics by consolidating multiple shipments into a single route, reducing transportation costs and minimizing inventory levels through synchronized supply. Direct shipment offers faster delivery times and reduced handling, ideal for perishable goods or urgent orders. The choice depends on factors like shipment volume, frequency, cost sensitivity, and delivery speed requirements in the supply chain.

Connection

Milk run delivery and direct shipment optimize supply chain efficiency by balancing transportation cost and speed. Milk run delivery consolidates multiple deliveries into a single route, reducing waste and ensuring consistent supply, while direct shipment focuses on fast, point-to-point delivery for urgent or bulk orders. Integrating these methods allows companies to tailor logistics strategies to inventory demands and lead times, improving overall distribution performance.

Key Terms

Transportation Efficiency

Direct shipment minimizes transit time by sending goods straight from supplier to customer, reducing handling and delays. Milk run delivery consolidates multiple shipments on a single route, enhancing load efficiency and lowering transportation costs. Explore more on how each method can optimize your supply chain logistics.

Delivery Scheduling

Direct shipment offers precise delivery scheduling by dispatching goods straight from the supplier to the customer, minimizing transit times and reducing handling delays. Milk run delivery involves a consolidated approach where a single vehicle collects shipments from multiple suppliers on a set schedule, optimizing route efficiency but requiring coordinated timing. Explore detailed comparisons of delivery scheduling strategies to determine the best fit for your supply chain needs.

Consolidation

Direct shipment involves sending goods straight from the supplier to the customer without intermediate stops, minimizing handling but potentially increasing transportation costs. Milk run delivery consolidates multiple pickups or deliveries into a single route, optimizing load efficiency and reducing transportation expenses through synchronized scheduling. Explore the advantages and applications of shipment consolidation to optimize your supply chain logistics.

Source and External Links

Direct Shipping: Definition, Advantages, Disadvantages - Direct shipping is a fulfillment method where goods are delivered directly from the supplier to the customer, bypassing warehouses or intermediaries, which can reduce logistics costs but presents risks such as no quality guarantee from the seller's side.

What Is Direct Shipping? Pros and Cons of Direct Shipping - Direct shipping is an in-house method where sellers handle their own inventory and ship products directly to customers, providing control over fulfillment and packaging, and often enabling faster and more personal delivery.

Direct Shipping: A Comprehensive Guide - Direct shipping sends products straight from supplier or manufacturer to customer, eliminating storage and warehousing for retailers and offering greater control over branding and shipping compared to dropshipping.

dowidth.com

dowidth.com