Milk run logistics streamlines supply chains by using a single vehicle to pick up or deliver goods from multiple suppliers or customers in one continuous route, reducing transportation costs and improving efficiency. Hub and Spoke logistics centralizes distribution through a main hub, where goods are sorted and dispatched to various spokes or destinations, optimizing inventory management and delivery schedules. Discover the advantages and applications of both systems to enhance your logistics strategy.

Why it is important

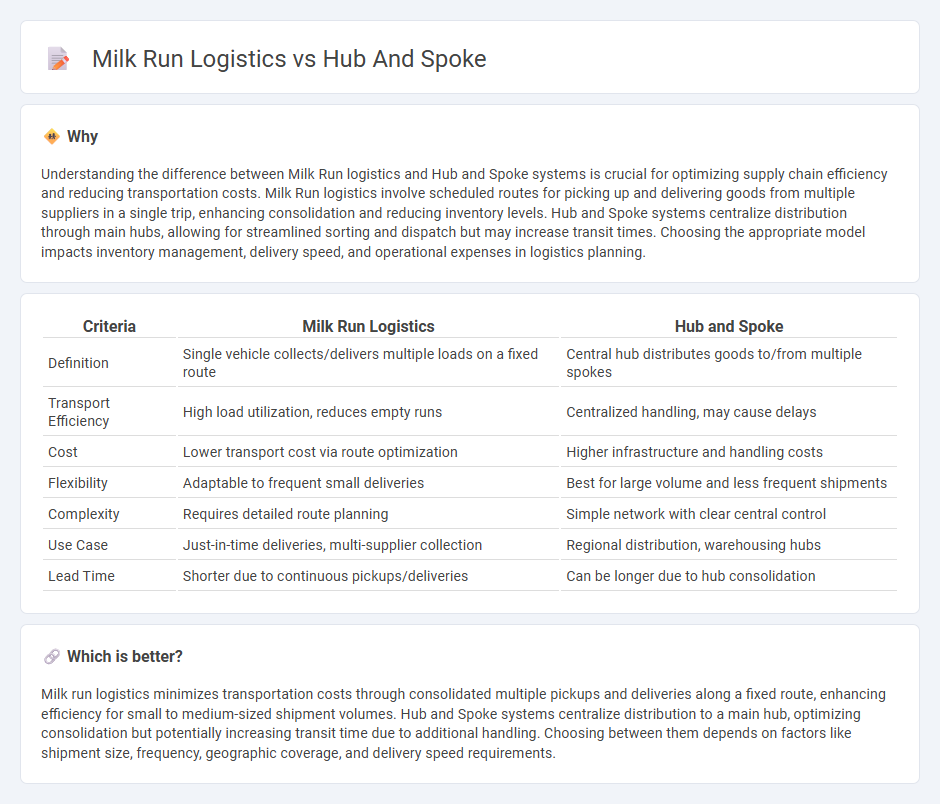

Understanding the difference between Milk Run logistics and Hub and Spoke systems is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk Run logistics involve scheduled routes for picking up and delivering goods from multiple suppliers in a single trip, enhancing consolidation and reducing inventory levels. Hub and Spoke systems centralize distribution through main hubs, allowing for streamlined sorting and dispatch but may increase transit times. Choosing the appropriate model impacts inventory management, delivery speed, and operational expenses in logistics planning.

Comparison Table

| Criteria | Milk Run Logistics | Hub and Spoke |

|---|---|---|

| Definition | Single vehicle collects/delivers multiple loads on a fixed route | Central hub distributes goods to/from multiple spokes |

| Transport Efficiency | High load utilization, reduces empty runs | Centralized handling, may cause delays |

| Cost | Lower transport cost via route optimization | Higher infrastructure and handling costs |

| Flexibility | Adaptable to frequent small deliveries | Best for large volume and less frequent shipments |

| Complexity | Requires detailed route planning | Simple network with clear central control |

| Use Case | Just-in-time deliveries, multi-supplier collection | Regional distribution, warehousing hubs |

| Lead Time | Shorter due to continuous pickups/deliveries | Can be longer due to hub consolidation |

Which is better?

Milk run logistics minimizes transportation costs through consolidated multiple pickups and deliveries along a fixed route, enhancing efficiency for small to medium-sized shipment volumes. Hub and Spoke systems centralize distribution to a main hub, optimizing consolidation but potentially increasing transit time due to additional handling. Choosing between them depends on factors like shipment size, frequency, geographic coverage, and delivery speed requirements.

Connection

Milk run logistics and Hub and Spoke models both optimize supply chain efficiency by centralizing distribution and minimizing transportation costs. Milk run logistics consolidates multiple deliveries into a single route to reduce inventory and streamline transportation, while Hub and Spoke systems utilize central hubs to coordinate shipments from various spokes, enhancing route optimization and load consolidation. The integration of these models enables companies to improve delivery frequency, reduce lead times, and lower overall logistical expenses.

Key Terms

Centralized Distribution

Centralized distribution in logistics leverages the hub and spoke model by consolidating inventory at a central hub to streamline shipments to multiple destinations, enhancing route efficiency and reducing transportation costs. In contrast, the milk run logistics approach optimizes deliveries through scheduled, frequent pickups and drop-offs along a fixed route, minimizing vehicle idle time and supporting just-in-time inventory management. Explore detailed comparisons and strategic benefits of these centralized distribution methods to optimize your supply chain operations.

Route Optimization

Hub and Spoke logistics centralizes shipments through a main hub, enabling efficient consolidation and streamlined distribution for optimized routes. Milk Run logistics uses a cyclical route collecting and delivering goods from multiple suppliers in a single trip, reducing transportation costs and improving load utilization. Explore how these route optimization strategies can enhance your logistics performance and cost efficiency.

Consolidation

Hub and Spoke logistics centralizes consolidation by channeling goods through a primary hub, optimizing route efficiency for bulk shipments across spokes. Milk run logistics emphasizes frequent, smaller consolidated pickups from multiple suppliers, reducing inventory costs and minimizing transport empty miles. Explore the advantages of each consolidation strategy to enhance your supply chain performance.

Source and External Links

What is a Hub-and-Spoke Network: 9 Tips, Benefits & ... - A hub-and-spoke network is a centralized structure where a central hub coordinates communication and resources with multiple spoke partner organizations, streamlining coordination and ensuring alignment without direct spoke-to-spoke interaction.

Spoke-hub distribution paradigm - The hub-and-spoke system organizes routes or connections so that outlying points (spokes) link directly to a central hub, optimizing transport, communication, or logistics, famously pioneered in commercial aviation by Delta Air Lines in 1955.

Hub-spoke network topology in Azure - In cloud networking, the hub-spoke topology features a central hub virtual network hosting shared services and managing connectivity, routing, and security policies for multiple spoke virtual networks, enabling controlled communication and resource sharing.

dowidth.com

dowidth.com