Cold chain logistics ensures the temperature-controlled transportation and storage of perishable goods, maintaining product integrity from origin to destination. Milk run logistics optimizes delivery routes by consolidating multiple shipments into a single trip, reducing costs and enhancing efficiency. Explore the advantages and applications of cold chain versus milk run logistics to optimize your supply chain.

Why it is important

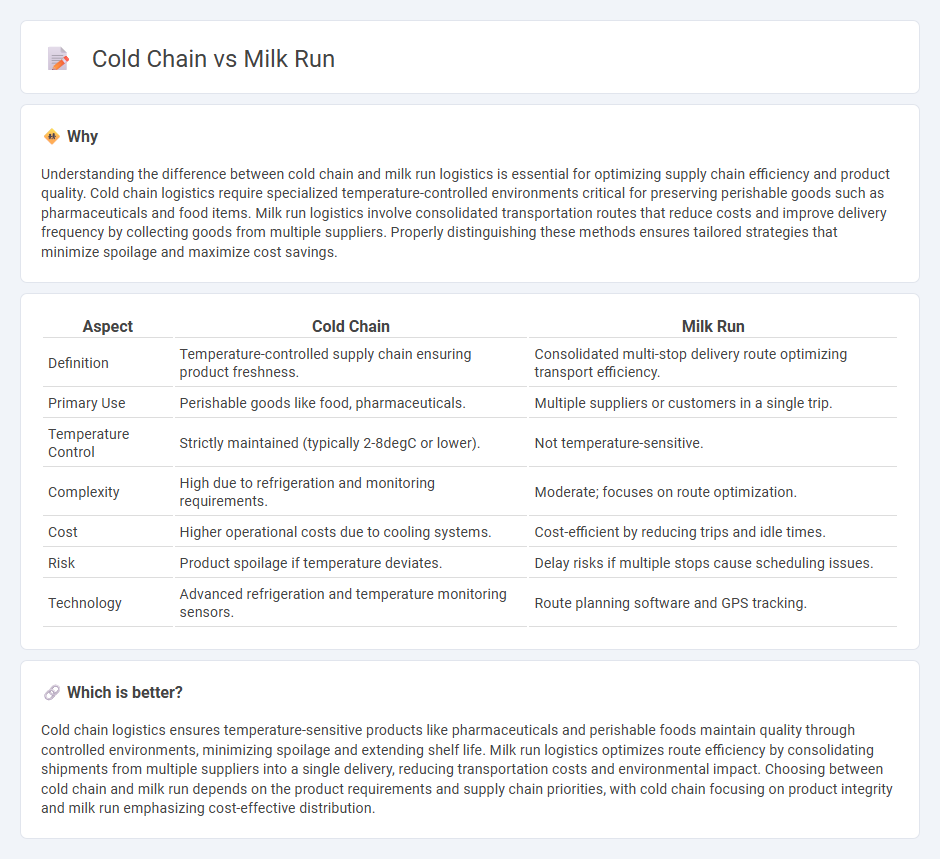

Understanding the difference between cold chain and milk run logistics is essential for optimizing supply chain efficiency and product quality. Cold chain logistics require specialized temperature-controlled environments critical for preserving perishable goods such as pharmaceuticals and food items. Milk run logistics involve consolidated transportation routes that reduce costs and improve delivery frequency by collecting goods from multiple suppliers. Properly distinguishing these methods ensures tailored strategies that minimize spoilage and maximize cost savings.

Comparison Table

| Aspect | Cold Chain | Milk Run |

|---|---|---|

| Definition | Temperature-controlled supply chain ensuring product freshness. | Consolidated multi-stop delivery route optimizing transport efficiency. |

| Primary Use | Perishable goods like food, pharmaceuticals. | Multiple suppliers or customers in a single trip. |

| Temperature Control | Strictly maintained (typically 2-8degC or lower). | Not temperature-sensitive. |

| Complexity | High due to refrigeration and monitoring requirements. | Moderate; focuses on route optimization. |

| Cost | Higher operational costs due to cooling systems. | Cost-efficient by reducing trips and idle times. |

| Risk | Product spoilage if temperature deviates. | Delay risks if multiple stops cause scheduling issues. |

| Technology | Advanced refrigeration and temperature monitoring sensors. | Route planning software and GPS tracking. |

Which is better?

Cold chain logistics ensures temperature-sensitive products like pharmaceuticals and perishable foods maintain quality through controlled environments, minimizing spoilage and extending shelf life. Milk run logistics optimizes route efficiency by consolidating shipments from multiple suppliers into a single delivery, reducing transportation costs and environmental impact. Choosing between cold chain and milk run depends on the product requirements and supply chain priorities, with cold chain focusing on product integrity and milk run emphasizing cost-effective distribution.

Connection

Cold chain logistics ensures temperature-controlled storage and transportation of perishable goods like dairy products, maintaining milk quality and safety. Milk run logistics optimize delivery efficiency by consolidating shipments from multiple suppliers into a single route, reducing transportation costs and emissions. Integrating cold chain with milk run operations enhances supply chain reliability for dairy distribution, preserving freshness while minimizing logistical expenses.

Key Terms

Route Optimization

Route optimization in milk run logistics focuses on efficient multi-stop delivery schedules to minimize distance and fuel consumption, ensuring timely collection and distribution of materials. In cold chain logistics, route planning prioritizes maintaining temperature-controlled environments throughout transit, reducing spoilage risk while adhering to strict delivery timelines. Explore detailed strategies for optimizing routes in both milk run and cold chain systems to enhance supply chain efficiency and product integrity.

Temperature Control

Milk run logistics consolidates multiple deliveries into a single route, optimizing efficiency and reducing transit times critical for maintaining strict temperature control in cold chain supply chains. Cold chain management relies heavily on precise temperature monitoring, using advanced sensors and insulated packaging to ensure perishable goods remain within required temperature ranges from production to delivery. Explore how integrating milk run strategies can enhance temperature control and overall cold chain reliability.

Consolidated Shipments

Consolidated shipments in milk run logistics optimize route efficiency by grouping multiple deliveries or pickups, reducing transportation costs and environmental impact. Cold chain consolidated shipments require precise temperature control throughout transit to maintain product quality and safety for perishable goods like pharmaceuticals and food. Explore how integrating consolidated shipments enhances supply chain performance and product integrity in your operations.

Source and External Links

Milk Run in Logistics: Meaning, Pros, & Cons - This article discusses the concept of milk runs in logistics, their origins, and how they streamline supply chains by consolidating deliveries from multiple suppliers.

What is a milk run in logistics? - This article explains the milk run delivery method, its advantages in logistics, and how it optimizes inventory management and transportation routes.

What Is a Milk Run? - This logistics glossary entry defines a milk run as a method for transporting mixed loads from various suppliers to a single customer, highlighting its role in efficient supply chain management.

dowidth.com

dowidth.com