Dynamic rerouting leverages real-time data and advanced algorithms to optimize delivery paths, reducing transit times and operational costs. Demand forecasting uses historical data and predictive analytics to anticipate customer needs, enabling efficient inventory management and resource allocation. Explore how integrating these strategies enhances supply chain resilience and responsiveness.

Why it is important

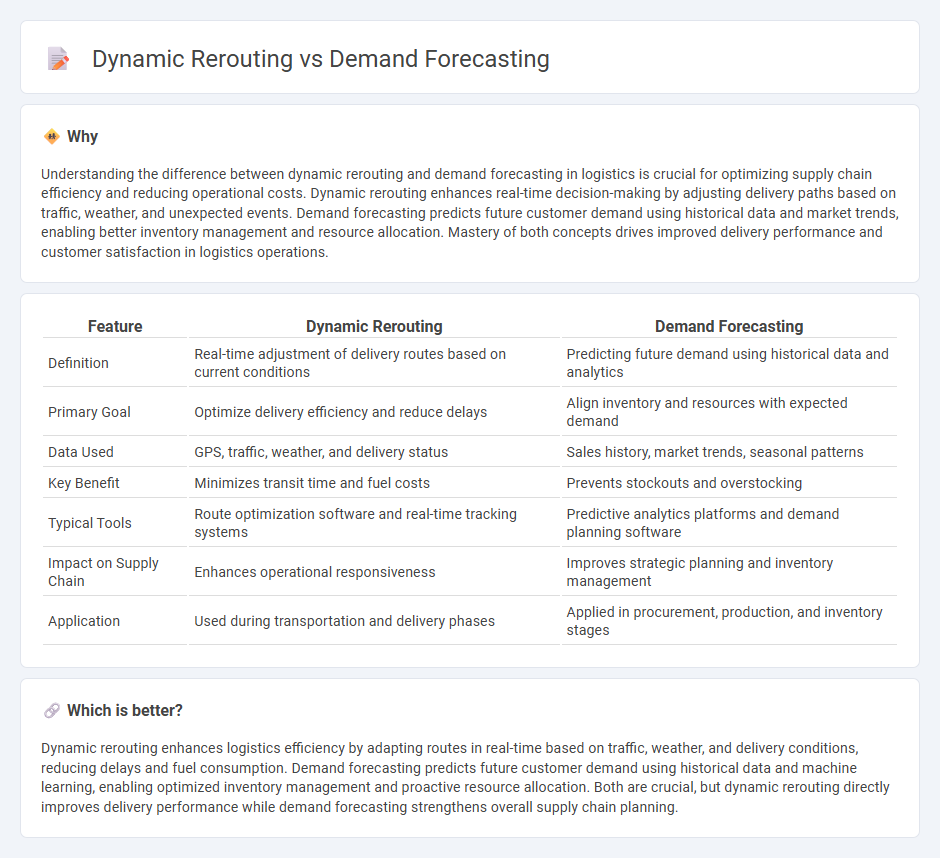

Understanding the difference between dynamic rerouting and demand forecasting in logistics is crucial for optimizing supply chain efficiency and reducing operational costs. Dynamic rerouting enhances real-time decision-making by adjusting delivery paths based on traffic, weather, and unexpected events. Demand forecasting predicts future customer demand using historical data and market trends, enabling better inventory management and resource allocation. Mastery of both concepts drives improved delivery performance and customer satisfaction in logistics operations.

Comparison Table

| Feature | Dynamic Rerouting | Demand Forecasting |

|---|---|---|

| Definition | Real-time adjustment of delivery routes based on current conditions | Predicting future demand using historical data and analytics |

| Primary Goal | Optimize delivery efficiency and reduce delays | Align inventory and resources with expected demand |

| Data Used | GPS, traffic, weather, and delivery status | Sales history, market trends, seasonal patterns |

| Key Benefit | Minimizes transit time and fuel costs | Prevents stockouts and overstocking |

| Typical Tools | Route optimization software and real-time tracking systems | Predictive analytics platforms and demand planning software |

| Impact on Supply Chain | Enhances operational responsiveness | Improves strategic planning and inventory management |

| Application | Used during transportation and delivery phases | Applied in procurement, production, and inventory stages |

Which is better?

Dynamic rerouting enhances logistics efficiency by adapting routes in real-time based on traffic, weather, and delivery conditions, reducing delays and fuel consumption. Demand forecasting predicts future customer demand using historical data and machine learning, enabling optimized inventory management and proactive resource allocation. Both are crucial, but dynamic rerouting directly improves delivery performance while demand forecasting strengthens overall supply chain planning.

Connection

Dynamic rerouting in logistics relies heavily on accurate demand forecasting to effectively adjust delivery routes based on real-time changes in customer orders and supply chain disruptions. Advanced machine learning algorithms analyze historical sales data and current market trends to predict demand fluctuations, enabling logistics systems to proactively reroute shipments and optimize resource allocation. This integration reduces delivery delays, minimizes transportation costs, and enhances overall supply chain agility.

Key Terms

**Demand Forecasting:**

Demand forecasting predicts future customer demand using historical sales data, market trends, and advanced analytics to optimize inventory management and supply chain operations. It enhances decision-making by reducing stockouts and overstock situations, improving overall operational efficiency. Explore more to understand how demand forecasting transforms supply chain strategies and boosts business performance.

Historical Data Analysis

Demand forecasting relies heavily on historical sales and consumption data to predict future product needs, optimizing inventory and supply chain efficiency. Dynamic rerouting uses historical traffic patterns and delivery times to adjust transportation routes in real-time, enhancing distribution speed and reducing costs. Explore how integrating historical data analysis in these strategies can transform operational performance.

Predictive Analytics

Demand forecasting utilizes predictive analytics to analyze historical sales data and market trends, enabling businesses to anticipate future product demand with accuracy. Dynamic rerouting leverages real-time predictive models to optimize logistics pathways, reducing delivery times and operational costs by adapting to current traffic and environmental conditions. Explore how integrating predictive analytics enhances both demand forecasting and dynamic rerouting for superior supply chain efficiency.

Source and External Links

Types of Demand Forecast - Demand forecasting uses predictive analysis of past data to estimate future customer demand, helping businesses optimize inventory, production, and pricing decisions through various methods like active forecasting, market research, and econometrics.

Demand Forecasting: A Complete Guide - Demand forecasting enables companies to predict future market demand, allowing them to optimize supply chains, reduce costs, and make data-driven decisions for improved business performance.

Demand forecasting: types, methods, and examples - Common demand forecasting methods include trend projection using past sales data, market research from customer surveys, and sales force composite involving frontline sales input to predict future product demand.

dowidth.com

dowidth.com