Micro-fulfillment centers are compact, automated facilities designed to streamline order processing close to end consumers, optimizing last-mile delivery efficiency in dense urban areas. Urban fulfillment centers also focus on proximity to customers but typically operate on a larger scale with broader inventory capacity, supporting quicker response times for high-demand metropolitan markets. Explore the differences to understand which fulfillment solution best suits your logistics needs.

Why it is important

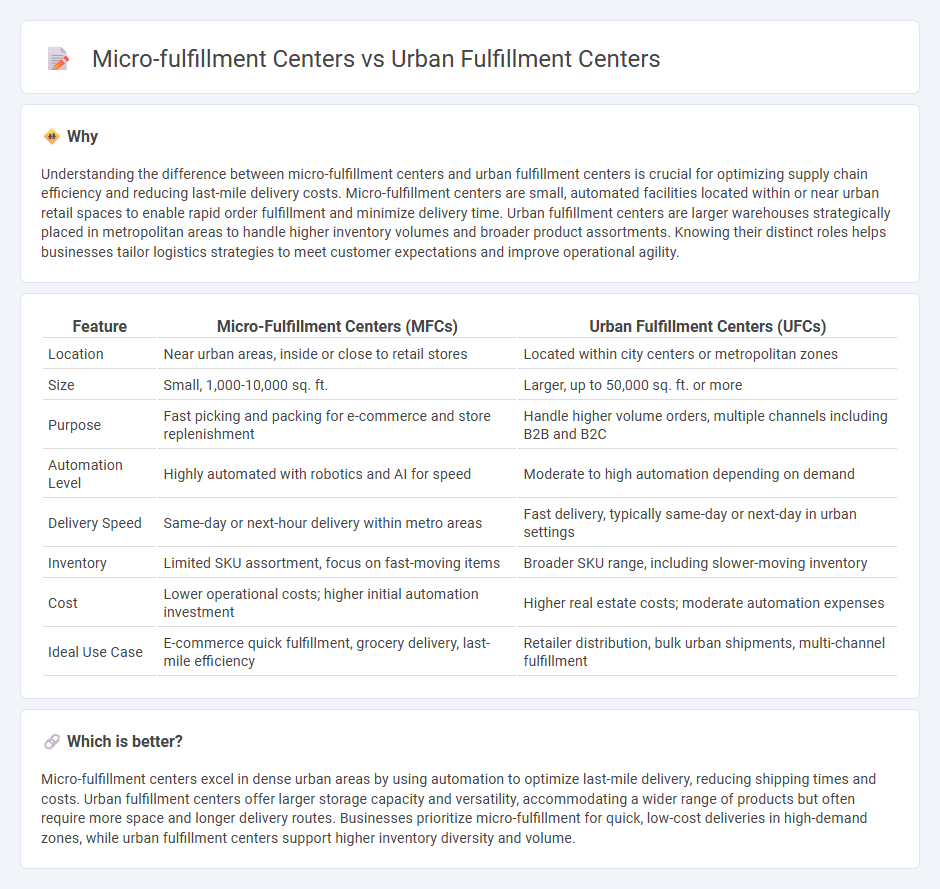

Understanding the difference between micro-fulfillment centers and urban fulfillment centers is crucial for optimizing supply chain efficiency and reducing last-mile delivery costs. Micro-fulfillment centers are small, automated facilities located within or near urban retail spaces to enable rapid order fulfillment and minimize delivery time. Urban fulfillment centers are larger warehouses strategically placed in metropolitan areas to handle higher inventory volumes and broader product assortments. Knowing their distinct roles helps businesses tailor logistics strategies to meet customer expectations and improve operational agility.

Comparison Table

| Feature | Micro-Fulfillment Centers (MFCs) | Urban Fulfillment Centers (UFCs) |

|---|---|---|

| Location | Near urban areas, inside or close to retail stores | Located within city centers or metropolitan zones |

| Size | Small, 1,000-10,000 sq. ft. | Larger, up to 50,000 sq. ft. or more |

| Purpose | Fast picking and packing for e-commerce and store replenishment | Handle higher volume orders, multiple channels including B2B and B2C |

| Automation Level | Highly automated with robotics and AI for speed | Moderate to high automation depending on demand |

| Delivery Speed | Same-day or next-hour delivery within metro areas | Fast delivery, typically same-day or next-day in urban settings |

| Inventory | Limited SKU assortment, focus on fast-moving items | Broader SKU range, including slower-moving inventory |

| Cost | Lower operational costs; higher initial automation investment | Higher real estate costs; moderate automation expenses |

| Ideal Use Case | E-commerce quick fulfillment, grocery delivery, last-mile efficiency | Retailer distribution, bulk urban shipments, multi-channel fulfillment |

Which is better?

Micro-fulfillment centers excel in dense urban areas by using automation to optimize last-mile delivery, reducing shipping times and costs. Urban fulfillment centers offer larger storage capacity and versatility, accommodating a wider range of products but often require more space and longer delivery routes. Businesses prioritize micro-fulfillment for quick, low-cost deliveries in high-demand zones, while urban fulfillment centers support higher inventory diversity and volume.

Connection

Micro-fulfillment centers (MFCs) and urban fulfillment centers (UFCs) are interconnected through their shared goal of enhancing last-mile delivery efficiency in dense metropolitan areas. MFCs utilize automated technology to rapidly process small, frequent orders, while UFCs serve as strategically located hubs that aggregate inventory closer to consumers, reducing transit times. This symbiotic relationship optimizes supply chain agility, lowers transportation costs, and supports the surge in e-commerce demand within urban environments.

Key Terms

Facility Size

Urban fulfillment centers typically range from 100,000 to 300,000 square feet, designed to handle large volumes of orders with extensive storage and sorting capabilities. Micro-fulfillment centers are much smaller, often between 5,000 and 20,000 square feet, optimized for rapid order processing and last-mile delivery within dense urban areas. Discover how choosing the right facility size can enhance efficiency and meet customer demand by learning more about these fulfillment solutions.

Delivery Radius

Urban fulfillment centers typically cover a broad delivery radius to service metropolitan and suburban areas efficiently, handling larger volume and variety of products. Micro-fulfillment centers operate within a much smaller radius, often just a few miles, enabling rapid last-mile delivery by leveraging automation and proximity to high-density urban populations. Explore how optimizing delivery radius in these center types can transform your supply chain strategies.

Automation Level

Urban fulfillment centers often employ extensive automation technologies such as conveyor systems, robotics, and automated storage and retrieval systems to manage large-scale inventory and high order volumes efficiently. Micro-fulfillment centers prioritize compact automation solutions like automated picking systems and AI-driven inventory management to optimize speed and accuracy within smaller urban spaces. Explore the advancements in automation levels to understand how each center type enhances the order fulfillment process.

Source and External Links

Urban Fulfillment: The Future of Retail Is Local, Fast, and Flexible - Urban fulfillment centers are small-city-focused logistics hubs that use innovative technology and supply chain strategies to meet demand for fast, flexible shopping and delivery in urban areas, with examples including Amazon's micro-fulfillment centers and Target's stores-as-distribution centers.

Urban Distribution Centers: Benefits and Last-Mile Advantages - Urban fulfillment centers reduce last-mile delivery time and costs by locating warehouses close to city customers, enabling faster same-day or next-day deliveries and improving returns processing for e-commerce goods in metropolitan areas.

The Benefits of Urban Fulfillment Centers - LGC Hospitality - Urban fulfillment centers enhance supply chain efficiency and customer satisfaction by allowing same-day delivery, easier store replenishment, and accommodating growth in e-commerce through closer proximity to consumers, often involving third-party logistics providers.

dowidth.com

dowidth.com