Freight visibility enhances supply chain transparency by providing real-time tracking of shipments, improving delivery accuracy and operational efficiency. Logistics automation streamlines processes through technology such as robotics and AI, reducing manual errors and accelerating fulfillment times. Explore how integrating freight visibility with logistics automation can optimize your supply chain performance.

Why it is important

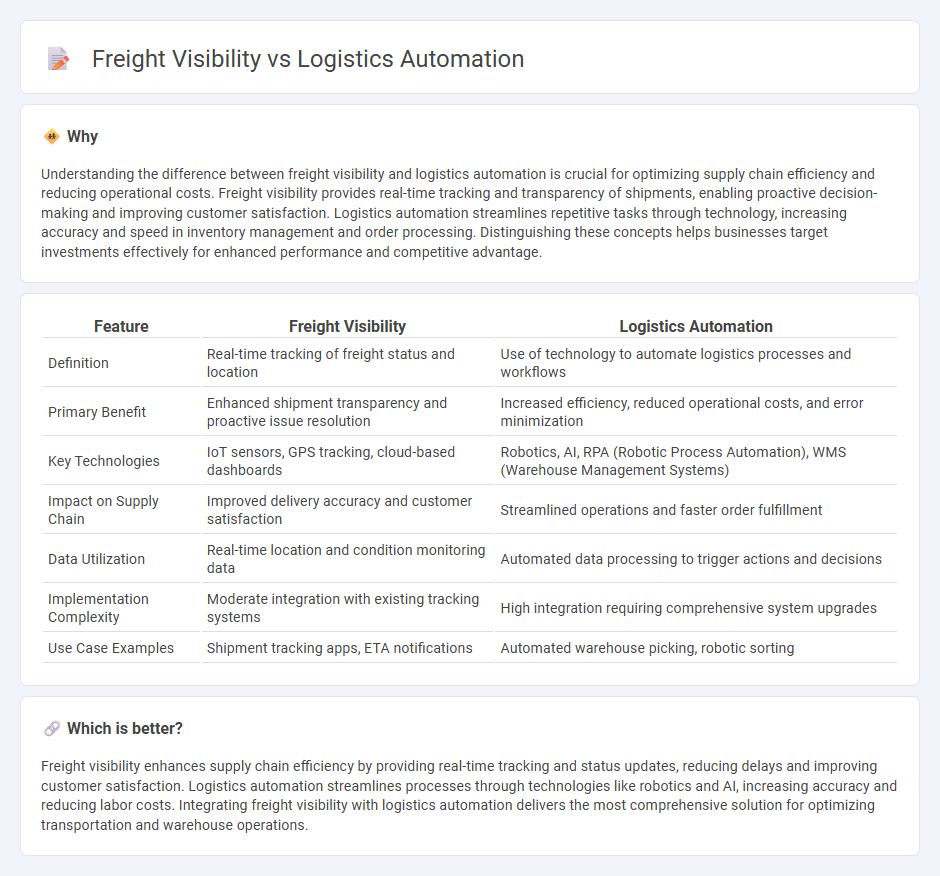

Understanding the difference between freight visibility and logistics automation is crucial for optimizing supply chain efficiency and reducing operational costs. Freight visibility provides real-time tracking and transparency of shipments, enabling proactive decision-making and improving customer satisfaction. Logistics automation streamlines repetitive tasks through technology, increasing accuracy and speed in inventory management and order processing. Distinguishing these concepts helps businesses target investments effectively for enhanced performance and competitive advantage.

Comparison Table

| Feature | Freight Visibility | Logistics Automation |

|---|---|---|

| Definition | Real-time tracking of freight status and location | Use of technology to automate logistics processes and workflows |

| Primary Benefit | Enhanced shipment transparency and proactive issue resolution | Increased efficiency, reduced operational costs, and error minimization |

| Key Technologies | IoT sensors, GPS tracking, cloud-based dashboards | Robotics, AI, RPA (Robotic Process Automation), WMS (Warehouse Management Systems) |

| Impact on Supply Chain | Improved delivery accuracy and customer satisfaction | Streamlined operations and faster order fulfillment |

| Data Utilization | Real-time location and condition monitoring data | Automated data processing to trigger actions and decisions |

| Implementation Complexity | Moderate integration with existing tracking systems | High integration requiring comprehensive system upgrades |

| Use Case Examples | Shipment tracking apps, ETA notifications | Automated warehouse picking, robotic sorting |

Which is better?

Freight visibility enhances supply chain efficiency by providing real-time tracking and status updates, reducing delays and improving customer satisfaction. Logistics automation streamlines processes through technologies like robotics and AI, increasing accuracy and reducing labor costs. Integrating freight visibility with logistics automation delivers the most comprehensive solution for optimizing transportation and warehouse operations.

Connection

Freight visibility enhances logistics automation by providing real-time data essential for optimizing route planning, inventory management, and shipment tracking. Automated systems rely on accurate, up-to-date freight information to trigger timely decisions, reduce delays, and improve supply chain efficiency. Integration of freight visibility technologies with logistics automation platforms drives transparency and operational agility across the entire distribution network.

Key Terms

**Logistics Automation:**

Logistics automation integrates advanced technologies such as AI, robotics, and IoT to streamline warehouse operations, inventory management, and transportation processes, significantly reducing manual errors and operational costs. By optimizing workflows and enhancing real-time data processing, logistics automation improves efficiency, scalability, and delivery speed within supply chains. Explore how logistics automation transforms industry standards and drives competitive advantage.

Robotics

Robotics in logistics automation enhances efficiency by streamlining repetitive tasks such as sorting, packing, and transportation, significantly reducing human error and operational costs. Freight visibility leverages IoT sensors and real-time tracking software to provide comprehensive insights into shipment location, condition, and estimated delivery times, improving supply chain transparency. Explore how integrating robotics with advanced freight visibility can revolutionize your logistics operations for greater precision and control.

Warehouse Management System (WMS)

Warehouse Management Systems (WMS) integrate logistics automation to streamline inventory handling, optimize order fulfillment, and reduce operational costs through real-time data processing and automated workflows. Freight visibility, enhanced by WMS, provides end-to-end tracking of shipments, ensuring transparency, improved delivery accuracy, and proactive exception management throughout the supply chain. Explore how advanced WMS solutions transform warehouse operations and freight monitoring for superior efficiency and customer satisfaction.

Source and External Links

Logistics automation - Logistics automation applies computer software and automated machinery to logistics operations to improve efficiency by automating goods-in processes, retrieval, dispatch, and repackaging, drastically reducing workforce needs and minimizing errors through technologies like AGVs (Automated Guided Vehicles).

5 Logistics Automation Strategies You Should be Aware Of - Logistics automation uses technologies such as AGVs, drones, AI, barcode scanning, and automated storage/retrieval systems to streamline supply chain tasks, reduce labor costs, boost accuracy, and improve customer satisfaction by minimizing errors and delays.

A Guide to Logistics Automation - Logistics automation enhances supply chain efficiency by automating order processing, inventory management, and transport scheduling, addressing industry challenges like cost pressures, workforce shortages, and delivery speed demands, while providing real-time visibility across the supply chain.

dowidth.com

dowidth.com