Milk run logistics optimize transportation by consolidating deliveries from multiple suppliers into a single route, reducing costs and improving efficiency. Pick-and-pack focuses on order fulfillment by selecting and packing individual items to meet specific customer orders rapidly. Explore more about how these strategies enhance supply chain performance and meet diverse distribution needs.

Why it is important

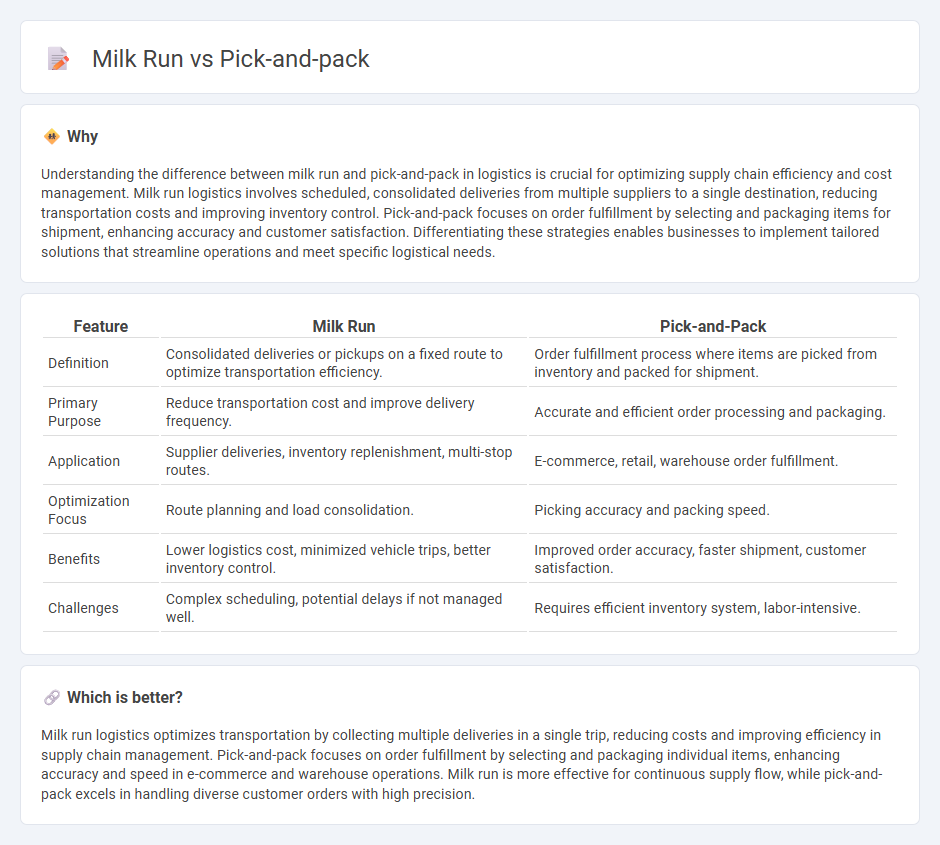

Understanding the difference between milk run and pick-and-pack in logistics is crucial for optimizing supply chain efficiency and cost management. Milk run logistics involves scheduled, consolidated deliveries from multiple suppliers to a single destination, reducing transportation costs and improving inventory control. Pick-and-pack focuses on order fulfillment by selecting and packaging items for shipment, enhancing accuracy and customer satisfaction. Differentiating these strategies enables businesses to implement tailored solutions that streamline operations and meet specific logistical needs.

Comparison Table

| Feature | Milk Run | Pick-and-Pack |

|---|---|---|

| Definition | Consolidated deliveries or pickups on a fixed route to optimize transportation efficiency. | Order fulfillment process where items are picked from inventory and packed for shipment. |

| Primary Purpose | Reduce transportation cost and improve delivery frequency. | Accurate and efficient order processing and packaging. |

| Application | Supplier deliveries, inventory replenishment, multi-stop routes. | E-commerce, retail, warehouse order fulfillment. |

| Optimization Focus | Route planning and load consolidation. | Picking accuracy and packing speed. |

| Benefits | Lower logistics cost, minimized vehicle trips, better inventory control. | Improved order accuracy, faster shipment, customer satisfaction. |

| Challenges | Complex scheduling, potential delays if not managed well. | Requires efficient inventory system, labor-intensive. |

Which is better?

Milk run logistics optimizes transportation by collecting multiple deliveries in a single trip, reducing costs and improving efficiency in supply chain management. Pick-and-pack focuses on order fulfillment by selecting and packaging individual items, enhancing accuracy and speed in e-commerce and warehouse operations. Milk run is more effective for continuous supply flow, while pick-and-pack excels in handling diverse customer orders with high precision.

Connection

Milk run logistics optimizes transportation by consolidating multiple deliveries into a single route, reducing costs and improving efficiency. Pick-and-pack processes complement milk run operations by preparing and organizing goods in precise quantities for timely dispatch. Together, these strategies streamline supply chain workflows, minimizing inventory holding and enhancing order fulfillment speed.

Key Terms

Order Fulfillment

Pick-and-pack optimizes order fulfillment by individually selecting and packaging items for specific customer orders, ensuring accuracy and speed in shipment. Milk run logistics streamline delivery by consolidating multiple shipments into a single route, reducing transportation costs and improving inventory turnover. Explore detailed comparisons to enhance your supply chain efficiency and order fulfillment strategies.

Route Optimization

Pick-and-pack optimizes route planning by consolidating orders and minimizing travel distance within warehouses, improving fulfillment speed and reducing handling costs. Milk run route optimization efficiently schedules multi-stop collection and delivery trips, lowering transportation expenses and enhancing supply chain responsiveness. Explore further to understand how each method transforms logistics efficiency through advanced route optimization strategies.

Consolidation

Pick-and-pack streamlines order fulfillment by individually selecting and packaging items for shipment, optimizing inventory turnover and reducing storage costs. Milk run consolidation involves scheduled, recurring routes that collect multiple suppliers' goods to distribute to various locations, maximizing load efficiency and minimizing transportation expenses. Explore how these consolidation strategies can enhance supply chain performance in your operations.

Source and External Links

Pick and Pack Fulfillment: An Ultimate Guide 2023 - Pick and pack is a warehouse process where items for customer orders are picked from shelves and packed for shipment using methods like piece picking, batch picking, zone picking, and wave picking suited to different business sizes and order volumes.

What Is Pick and Pack? Improving Warehouse Ops - Pick and pack is a fulfillment process consisting of order receiving, picking, packing, and shipping, crucial for efficient ecommerce operations and typically supported by integrated warehouse management systems.

What is Pick and Pack? What Does It Mean? - Pick and pack is a fulfillment method where individual items are selected from master cartons for small ecommerce orders and packed into packages addressed to specific customers, reducing freight and handling costs.

dowidth.com

dowidth.com