Drop shipping streamlines order fulfillment by directly shipping products from suppliers to customers, reducing inventory costs and warehouse management. Pick and pack involves storing inventory onsite, selecting items per order, and packaging them for shipment, allowing greater control over stock and faster delivery times. Explore the differences between drop shipping and pick and pack to optimize your logistics strategy.

Why it is important

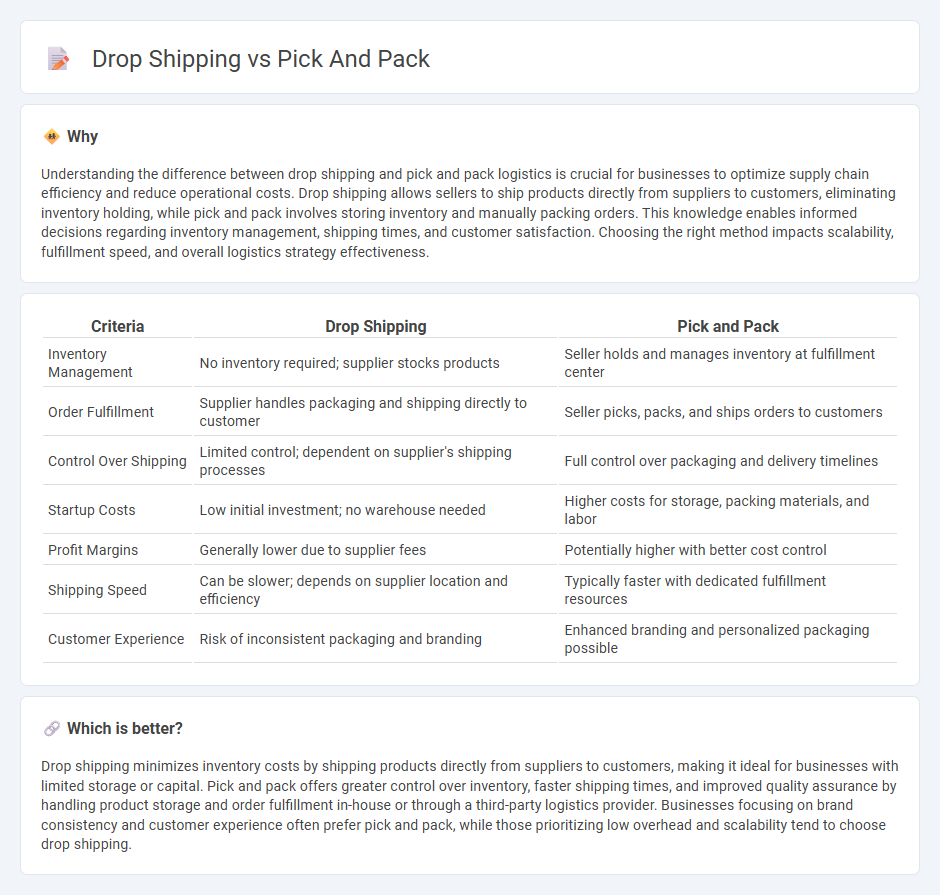

Understanding the difference between drop shipping and pick and pack logistics is crucial for businesses to optimize supply chain efficiency and reduce operational costs. Drop shipping allows sellers to ship products directly from suppliers to customers, eliminating inventory holding, while pick and pack involves storing inventory and manually packing orders. This knowledge enables informed decisions regarding inventory management, shipping times, and customer satisfaction. Choosing the right method impacts scalability, fulfillment speed, and overall logistics strategy effectiveness.

Comparison Table

| Criteria | Drop Shipping | Pick and Pack |

|---|---|---|

| Inventory Management | No inventory required; supplier stocks products | Seller holds and manages inventory at fulfillment center |

| Order Fulfillment | Supplier handles packaging and shipping directly to customer | Seller picks, packs, and ships orders to customers |

| Control Over Shipping | Limited control; dependent on supplier's shipping processes | Full control over packaging and delivery timelines |

| Startup Costs | Low initial investment; no warehouse needed | Higher costs for storage, packing materials, and labor |

| Profit Margins | Generally lower due to supplier fees | Potentially higher with better cost control |

| Shipping Speed | Can be slower; depends on supplier location and efficiency | Typically faster with dedicated fulfillment resources |

| Customer Experience | Risk of inconsistent packaging and branding | Enhanced branding and personalized packaging possible |

Which is better?

Drop shipping minimizes inventory costs by shipping products directly from suppliers to customers, making it ideal for businesses with limited storage or capital. Pick and pack offers greater control over inventory, faster shipping times, and improved quality assurance by handling product storage and order fulfillment in-house or through a third-party logistics provider. Businesses focusing on brand consistency and customer experience often prefer pick and pack, while those prioritizing low overhead and scalability tend to choose drop shipping.

Connection

Drop shipping and pick and pack are integral components of modern logistics, streamlining order fulfillment processes by minimizing inventory handling. In drop shipping, retailers directly forward customer orders to suppliers who then handle storage and shipping, reducing the need for warehousing. Pick and pack services support drop shipping by accurately selecting and packaging products, ensuring rapid and efficient delivery, thereby enhancing supply chain efficiency.

Key Terms

Inventory Management

Pick and pack inventory management requires businesses to store, organize, and handle products within their own warehouse, allowing for direct control over stock levels and order accuracy. Drop shipping eliminates the need for holding inventory by relying on suppliers to ship products directly to customers, reducing overhead but limiting immediate oversight of stock availability. Explore the advantages and challenges of each method to optimize your supply chain strategy.

Order Fulfillment

Pick and pack involves warehouses storing products and preparing orders by selecting and packaging items before shipping to customers, offering control over inventory and faster delivery times. Drop shipping eliminates inventory holding by directly forwarding customer orders to suppliers who ship products, reducing overhead but potentially extending delivery periods and limiting quality control. Discover the best order fulfillment strategy to optimize your supply chain efficiency and customer satisfaction.

Shipping Method

Pick and pack involves storing inventory in a warehouse where items are selected, packed, and shipped directly to customers, ensuring control over packaging and shipping speed. Drop shipping eliminates the need for inventory management by partnering with suppliers who ship products directly to customers, reducing overhead but potentially increasing delivery times. Explore detailed comparisons of pick and pack versus drop shipping methods to optimize your e-commerce fulfillment strategy.

Source and External Links

Pick and Pack Fulfillment Strategies To Improve ... - Pick and pack fulfillment is a process where warehouse staff pick specific items from inventory based on customer orders, then pack them carefully for shipment, following four main stages: order receiving, order picking, order packing, and order shipping to ensure fast and accurate delivery.

What are Pick and Pack Services? - Pick and pack services cover order fulfillment from selecting items (picking) in the warehouse to sorting, packing with care to avoid damage, and shipping, which optimizes efficiency and accuracy to enhance customer satisfaction.

What Is Pick and Pack? Improving Warehouse Ops - Pick and pack is a warehouse fulfillment process involving selecting items from inventory and packing them for shipping, involving steps like order receiving, picking, packing, and shipping, with techniques to increase speed and accuracy in warehouse operations.

dowidth.com

dowidth.com