Cold chain traceability ensures precise monitoring of temperature-sensitive products throughout the supply chain, reducing spoilage and compliance risks in industries like pharmaceuticals and food. Warehouse automation enhances efficiency by integrating robotics, IoT sensors, and real-time data analytics to optimize inventory management and order fulfillment. Discover how combining cold chain traceability with warehouse automation revolutionizes logistics performance and reliability.

Why it is important

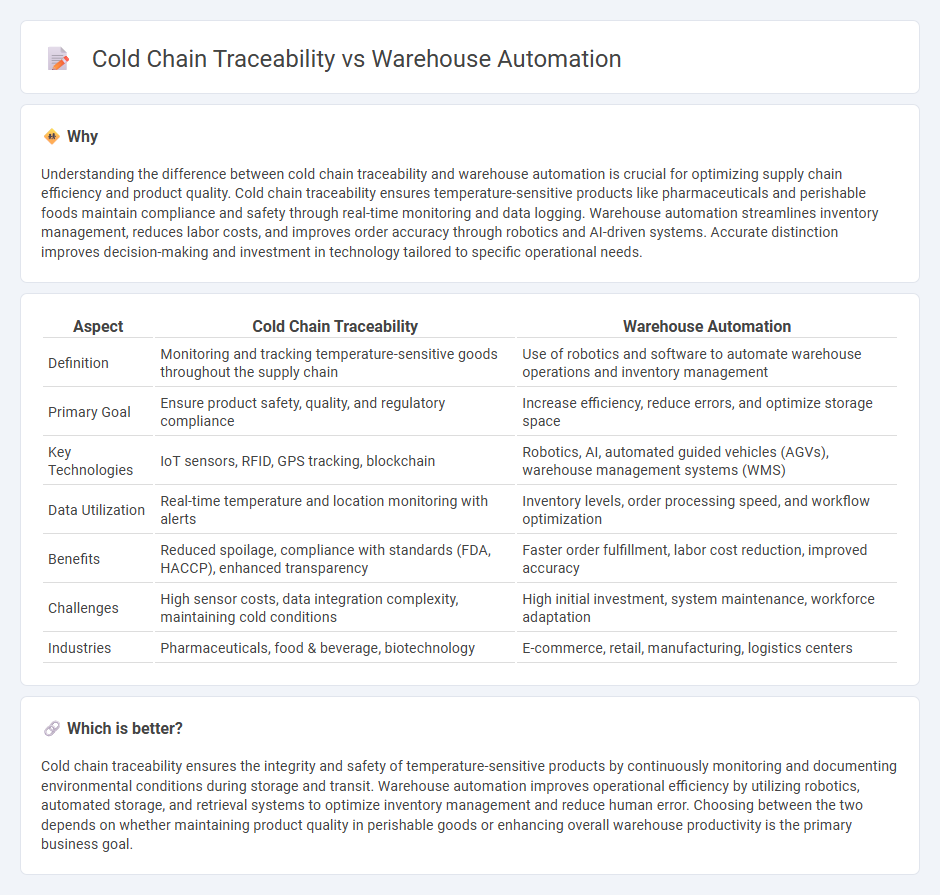

Understanding the difference between cold chain traceability and warehouse automation is crucial for optimizing supply chain efficiency and product quality. Cold chain traceability ensures temperature-sensitive products like pharmaceuticals and perishable foods maintain compliance and safety through real-time monitoring and data logging. Warehouse automation streamlines inventory management, reduces labor costs, and improves order accuracy through robotics and AI-driven systems. Accurate distinction improves decision-making and investment in technology tailored to specific operational needs.

Comparison Table

| Aspect | Cold Chain Traceability | Warehouse Automation |

|---|---|---|

| Definition | Monitoring and tracking temperature-sensitive goods throughout the supply chain | Use of robotics and software to automate warehouse operations and inventory management |

| Primary Goal | Ensure product safety, quality, and regulatory compliance | Increase efficiency, reduce errors, and optimize storage space |

| Key Technologies | IoT sensors, RFID, GPS tracking, blockchain | Robotics, AI, automated guided vehicles (AGVs), warehouse management systems (WMS) |

| Data Utilization | Real-time temperature and location monitoring with alerts | Inventory levels, order processing speed, and workflow optimization |

| Benefits | Reduced spoilage, compliance with standards (FDA, HACCP), enhanced transparency | Faster order fulfillment, labor cost reduction, improved accuracy |

| Challenges | High sensor costs, data integration complexity, maintaining cold conditions | High initial investment, system maintenance, workforce adaptation |

| Industries | Pharmaceuticals, food & beverage, biotechnology | E-commerce, retail, manufacturing, logistics centers |

Which is better?

Cold chain traceability ensures the integrity and safety of temperature-sensitive products by continuously monitoring and documenting environmental conditions during storage and transit. Warehouse automation improves operational efficiency by utilizing robotics, automated storage, and retrieval systems to optimize inventory management and reduce human error. Choosing between the two depends on whether maintaining product quality in perishable goods or enhancing overall warehouse productivity is the primary business goal.

Connection

Cold chain traceability relies heavily on warehouse automation to ensure precise temperature monitoring and real-time data capture throughout storage and handling processes. Automated systems in warehouses enable seamless tracking of perishable goods, reducing human error and enhancing compliance with safety standards. Integration of IoT sensors and automated inventory management improves transparency, ensuring product integrity from receipt to dispatch.

Key Terms

Warehouse Automation:

Warehouse automation enhances operational efficiency by integrating robotics, automated guided vehicles (AGVs), and advanced inventory management systems, resulting in reduced labor costs and increased throughput. Real-time data analytics and IoT-enabled sensors optimize stock handling and minimize errors within large-scale facilities. Discover how cutting-edge warehouse automation technologies can revolutionize your supply chain management.

Automated Storage and Retrieval System (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) significantly enhance warehouse automation by increasing picking accuracy, reducing labor costs, and optimizing inventory management. In cold chain traceability, AS/RS ensures precise temperature-controlled storage and real-time monitoring, critical for maintaining product integrity in pharmaceuticals and perishable goods. Explore how integrating AS/RS can transform your cold chain operations for improved efficiency and compliance.

Robotics Process Automation (RPA)

Warehouse automation leverages Robotics Process Automation (RPA) to streamline inventory management, order fulfillment, and real-time data tracking, enhancing operational efficiency and accuracy. Cold chain traceability integrates RPA to monitor temperature-sensitive products through automated data capture, ensuring compliance with safety standards and reducing spoilage risks. Discover how RPA bridges the gap between warehouse automation and cold chain traceability for optimized supply chain management.

Source and External Links

Warehouse Automation [Types + 2025 Technology Trends] - Modula - Warehouse automation involves technologies such as robots and automated material handling equipment, and implementing it requires assessing current processes, defining goals, researching solutions, making a plan and budget, choosing the right automation type, and training employees.

Warehouse Automation Explained: Trends, Types & Best Practices - Warehouse automation automates inventory movement with minimal human help through steps including forming an implementation team, collecting data, refining inventory controls, implementing a warehouse management system (WMS), and selecting automation types aligned with operational goals.

13 Warehouse Automation Trends in 2025 - Conger Industries - Implementing warehouse automation involves thorough preparation like feasibility studies, goal setting, budget planning, and stakeholder involvement, followed by selecting hardware like autonomous robots and integrating automation with WMS, ERP, or TMS systems for optimized operations.

dowidth.com

dowidth.com