Predictive fleet maintenance leverages real-time data analytics and IoT sensors to forecast vehicle wear and prevent breakdowns, optimizing operational efficiency and reducing downtime. Cold chain management focuses on maintaining temperature-controlled environments throughout the logistics process, ensuring the integrity and safety of perishable goods like pharmaceuticals, food, and chemicals. Explore how integrating predictive maintenance with cold chain management can enhance reliability and cost-effectiveness in logistics operations.

Why it is important

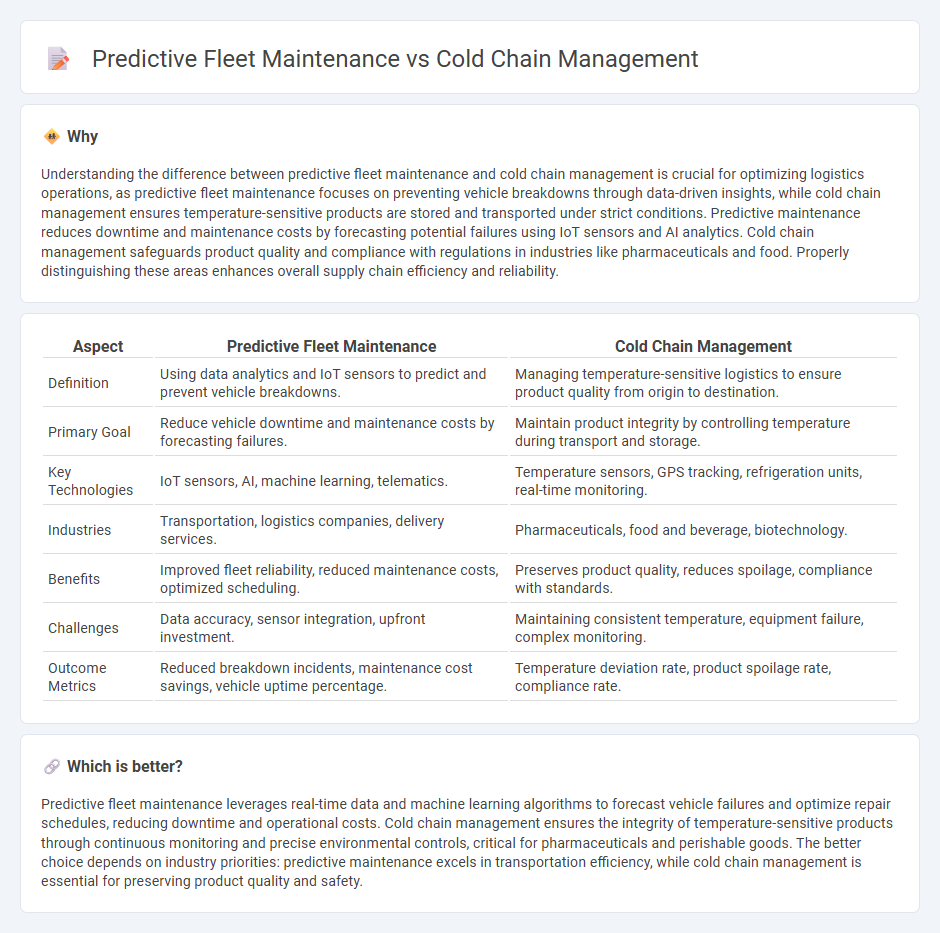

Understanding the difference between predictive fleet maintenance and cold chain management is crucial for optimizing logistics operations, as predictive fleet maintenance focuses on preventing vehicle breakdowns through data-driven insights, while cold chain management ensures temperature-sensitive products are stored and transported under strict conditions. Predictive maintenance reduces downtime and maintenance costs by forecasting potential failures using IoT sensors and AI analytics. Cold chain management safeguards product quality and compliance with regulations in industries like pharmaceuticals and food. Properly distinguishing these areas enhances overall supply chain efficiency and reliability.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Cold Chain Management |

|---|---|---|

| Definition | Using data analytics and IoT sensors to predict and prevent vehicle breakdowns. | Managing temperature-sensitive logistics to ensure product quality from origin to destination. |

| Primary Goal | Reduce vehicle downtime and maintenance costs by forecasting failures. | Maintain product integrity by controlling temperature during transport and storage. |

| Key Technologies | IoT sensors, AI, machine learning, telematics. | Temperature sensors, GPS tracking, refrigeration units, real-time monitoring. |

| Industries | Transportation, logistics companies, delivery services. | Pharmaceuticals, food and beverage, biotechnology. |

| Benefits | Improved fleet reliability, reduced maintenance costs, optimized scheduling. | Preserves product quality, reduces spoilage, compliance with standards. |

| Challenges | Data accuracy, sensor integration, upfront investment. | Maintaining consistent temperature, equipment failure, complex monitoring. |

| Outcome Metrics | Reduced breakdown incidents, maintenance cost savings, vehicle uptime percentage. | Temperature deviation rate, product spoilage rate, compliance rate. |

Which is better?

Predictive fleet maintenance leverages real-time data and machine learning algorithms to forecast vehicle failures and optimize repair schedules, reducing downtime and operational costs. Cold chain management ensures the integrity of temperature-sensitive products through continuous monitoring and precise environmental controls, critical for pharmaceuticals and perishable goods. The better choice depends on industry priorities: predictive maintenance excels in transportation efficiency, while cold chain management is essential for preserving product quality and safety.

Connection

Predictive fleet maintenance leverages real-time data analytics to anticipate vehicle issues, ensuring consistent performance crucial for cold chain logistics where temperature-sensitive goods require uninterrupted transport. Integrating predictive maintenance minimizes breakdown risks, preserving the integrity of perishable products and enhancing supply chain reliability. This connection optimizes operational efficiency by reducing unexpected downtime and maintaining strict temperature controls throughout delivery routes.

Key Terms

**Cold Chain Management:**

Cold chain management ensures the uninterrupted temperature-controlled supply of perishable goods from origin to destination, crucial for pharmaceuticals, food, and chemicals. Advanced sensors and IoT devices monitor and maintain optimal conditions, reducing spoilage and compliance risks. Discover how integrating technology enhances cold chain efficiency and product integrity.

Temperature Monitoring

Cold chain management relies heavily on precise temperature monitoring to ensure perishable goods remain within safe temperature ranges during storage and transportation, preventing spoilage and maintaining quality. Predictive fleet maintenance uses sensor data, including temperature readings, to anticipate vehicle component failures and optimize maintenance schedules, improving fleet reliability and reducing downtime. Explore how integrating advanced temperature monitoring technologies can enhance both cold chain integrity and predictive maintenance strategies.

Refrigerated Transport

Cold chain management ensures the integrity of temperature-sensitive goods during refrigerated transport by utilizing real-time monitoring, insulated containers, and climate-controlled vehicles. Predictive fleet maintenance leverages IoT sensors and data analytics to forecast vehicle malfunctions, minimizing downtime and maintaining optimal operation of refrigerated trucks. Explore the latest advancements in refrigerated transport to enhance cold chain efficiency and fleet reliability.

Source and External Links

What is Cold Chain Management? - Cold chain management involves managing all phases of temperature-sensitive products in transit, storage, and delivery using specialized equipment, packaging, transportation, and tracking to maintain product quality and integrity.

What is Cold Chain Management & Logistics? - Cold chain management is the process of controlling and maintaining required temperatures of perishables throughout the supply chain, emphasizing regulation compliance, cold packing techniques, and real-time temperature monitoring technologies.

PHARMACEUTICAL COLD CHAIN MANAGEMENT IN HEALTH SYSTEMS (PDF) - Pharmaceutical cold chain management requires preparedness plans, inventory control, system redundancy, and holistic supply chain approaches to minimize losses and maintain critical product integrity during disruptions.

dowidth.com

dowidth.com