Milk run and pool distribution are two efficient logistics strategies designed to optimize transportation and reduce costs. Milk run focuses on a single vehicle collecting or delivering goods from multiple suppliers or customers in a loop, enhancing load consolidation and reducing trips. Explore the differences and benefits of these distribution methods to improve your supply chain efficiency.

Why it is important

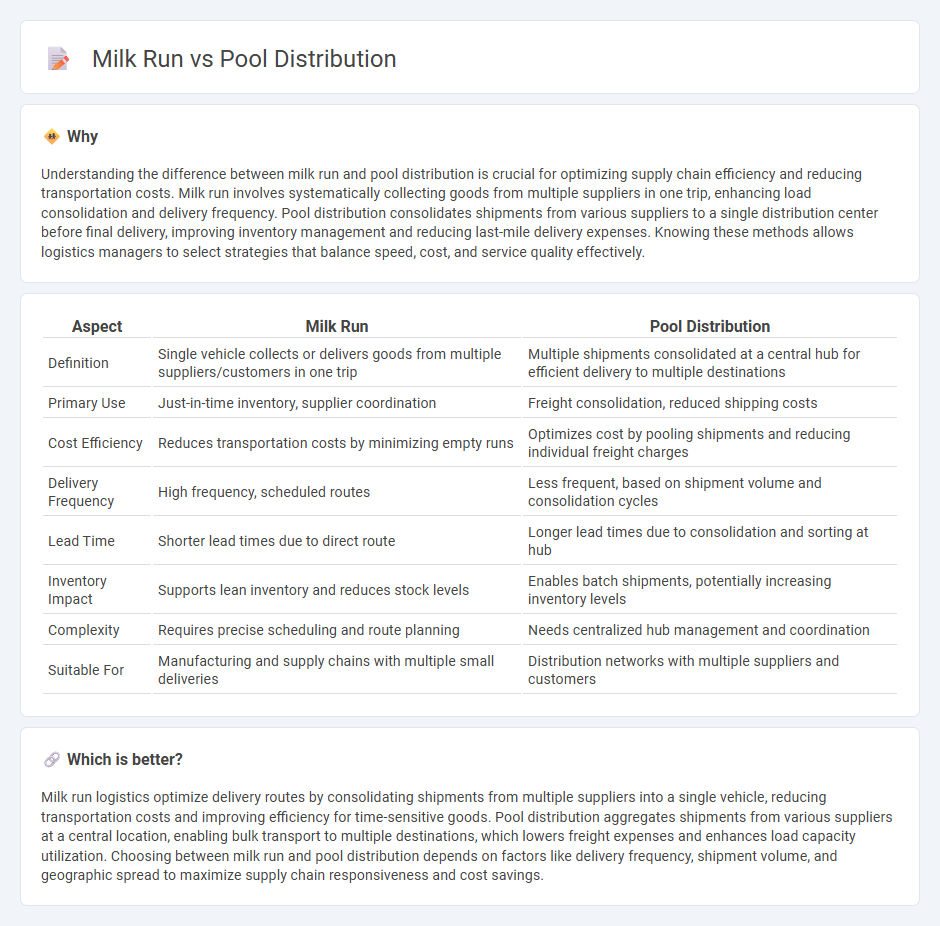

Understanding the difference between milk run and pool distribution is crucial for optimizing supply chain efficiency and reducing transportation costs. Milk run involves systematically collecting goods from multiple suppliers in one trip, enhancing load consolidation and delivery frequency. Pool distribution consolidates shipments from various suppliers to a single distribution center before final delivery, improving inventory management and reducing last-mile delivery expenses. Knowing these methods allows logistics managers to select strategies that balance speed, cost, and service quality effectively.

Comparison Table

| Aspect | Milk Run | Pool Distribution |

|---|---|---|

| Definition | Single vehicle collects or delivers goods from multiple suppliers/customers in one trip | Multiple shipments consolidated at a central hub for efficient delivery to multiple destinations |

| Primary Use | Just-in-time inventory, supplier coordination | Freight consolidation, reduced shipping costs |

| Cost Efficiency | Reduces transportation costs by minimizing empty runs | Optimizes cost by pooling shipments and reducing individual freight charges |

| Delivery Frequency | High frequency, scheduled routes | Less frequent, based on shipment volume and consolidation cycles |

| Lead Time | Shorter lead times due to direct route | Longer lead times due to consolidation and sorting at hub |

| Inventory Impact | Supports lean inventory and reduces stock levels | Enables batch shipments, potentially increasing inventory levels |

| Complexity | Requires precise scheduling and route planning | Needs centralized hub management and coordination |

| Suitable For | Manufacturing and supply chains with multiple small deliveries | Distribution networks with multiple suppliers and customers |

Which is better?

Milk run logistics optimize delivery routes by consolidating shipments from multiple suppliers into a single vehicle, reducing transportation costs and improving efficiency for time-sensitive goods. Pool distribution aggregates shipments from various suppliers at a central location, enabling bulk transport to multiple destinations, which lowers freight expenses and enhances load capacity utilization. Choosing between milk run and pool distribution depends on factors like delivery frequency, shipment volume, and geographic spread to maximize supply chain responsiveness and cost savings.

Connection

Milk run and pool distribution optimize supply chain efficiency by consolidating shipments from multiple suppliers into a single delivery route. Milk run routes collect smaller loads to reduce transportation costs and improve delivery frequency, while pool distribution centralizes inventory at a distribution hub for consolidated outbound shipments. Both methods enhance logistics coordination, minimize transportation expenses, and reduce carbon emissions through optimized routing and load consolidation.

Key Terms

Consolidation

Pool distribution and milk run are two key consolidation strategies in supply chain management, with pool distribution centralizing shipments from multiple suppliers at a single distribution center to optimize freight costs and delivery efficiency. Milk run operates through scheduled, repeated routes collecting smaller loads from several suppliers to consolidate shipments before reaching the destination, minimizing transportation costs and reducing carbon footprint. Explore how each method enhances logistics efficiency and cost reduction in modern supply chains.

Route optimization

Pool distribution consolidates shipments from multiple suppliers to optimize delivery routes, reducing transportation costs and improving load efficiency. Milk run route optimization schedules regular, cyclic pickups and deliveries, minimizing empty miles and enhancing supply chain reliability. Explore detailed strategies to optimize both pool distribution and milk run routes for maximum efficiency.

Delivery frequency

Pool distribution consolidates multiple deliveries into a single trip, reducing delivery frequency but maximizing load efficiency and cost savings. Milk run systems execute scheduled, repetitive deliveries with higher frequency, ensuring consistent inventory replenishment and lower lead times. Explore detailed comparisons to optimize your supply chain delivery frequency strategy.

Source and External Links

Pool Distribution - Lanter Distributing - Pool distribution consolidates many orders consigned for delivery within a specific geographic region, shipping them to a regional cross-dock terminal where orders are sorted and delivered locally, offering significant transportation cost savings and efficient delivery for high volumes of LTL shipments.

Pool Distribution Services in the Mid-Atlantic, Northeast & ... - National Delivery Systems - Pool distribution services consolidate shipments for multiple locations from regional warehouses, providing retailers and distributors improved supply chain efficiency through on-time service, technology-driven visibility, and cost reductions.

What is Pool Distribution? - Expak - Pool distribution is a shipping method where multiple shipments bound for a geographic region are consolidated into a single truckload, then delivered from a regional pool point or terminal to individual destinations, optimizing space and delivery efficiency.

dowidth.com

dowidth.com