Cold chain management ensures the integrity of temperature-sensitive products by maintaining specific conditions throughout storage and transportation, crucial for pharmaceuticals and perishable foods. Logistics automation leverages technologies like robotics, AI, and IoT to optimize supply chain efficiency, reduce errors, and accelerate delivery times. Discover how integrating cold chain management with logistics automation can revolutionize supply chain operations.

Why it is important

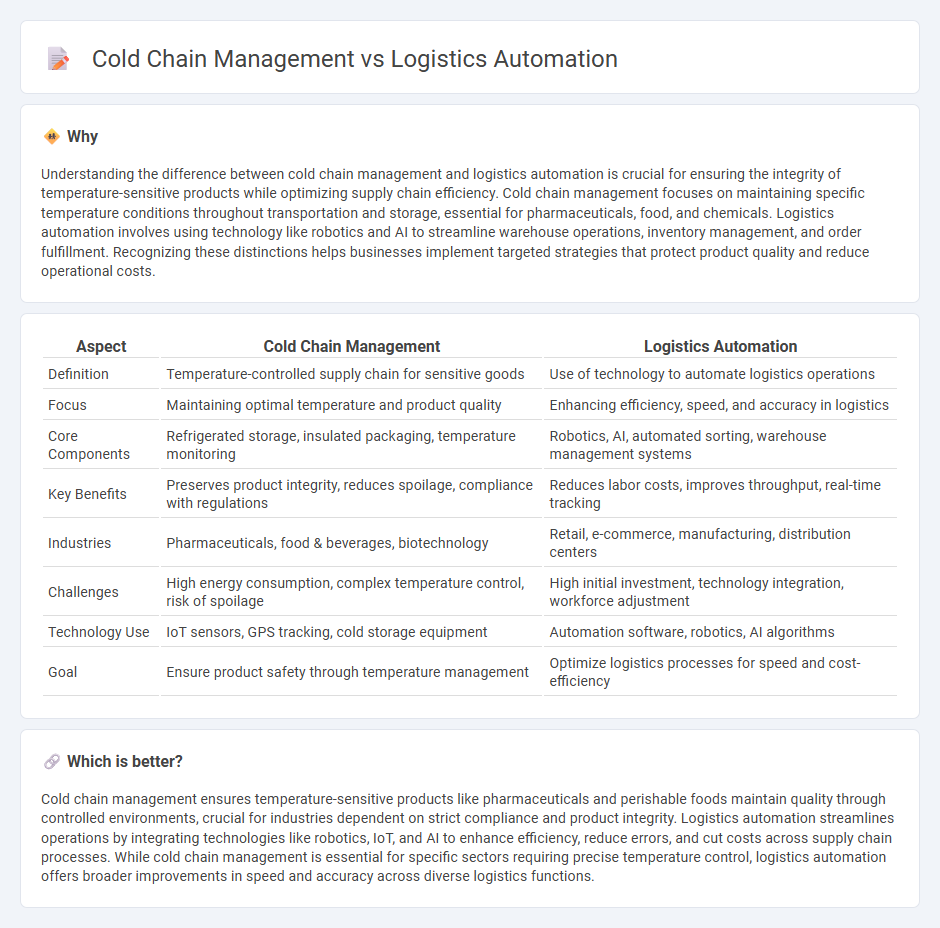

Understanding the difference between cold chain management and logistics automation is crucial for ensuring the integrity of temperature-sensitive products while optimizing supply chain efficiency. Cold chain management focuses on maintaining specific temperature conditions throughout transportation and storage, essential for pharmaceuticals, food, and chemicals. Logistics automation involves using technology like robotics and AI to streamline warehouse operations, inventory management, and order fulfillment. Recognizing these distinctions helps businesses implement targeted strategies that protect product quality and reduce operational costs.

Comparison Table

| Aspect | Cold Chain Management | Logistics Automation |

|---|---|---|

| Definition | Temperature-controlled supply chain for sensitive goods | Use of technology to automate logistics operations |

| Focus | Maintaining optimal temperature and product quality | Enhancing efficiency, speed, and accuracy in logistics |

| Core Components | Refrigerated storage, insulated packaging, temperature monitoring | Robotics, AI, automated sorting, warehouse management systems |

| Key Benefits | Preserves product integrity, reduces spoilage, compliance with regulations | Reduces labor costs, improves throughput, real-time tracking |

| Industries | Pharmaceuticals, food & beverages, biotechnology | Retail, e-commerce, manufacturing, distribution centers |

| Challenges | High energy consumption, complex temperature control, risk of spoilage | High initial investment, technology integration, workforce adjustment |

| Technology Use | IoT sensors, GPS tracking, cold storage equipment | Automation software, robotics, AI algorithms |

| Goal | Ensure product safety through temperature management | Optimize logistics processes for speed and cost-efficiency |

Which is better?

Cold chain management ensures temperature-sensitive products like pharmaceuticals and perishable foods maintain quality through controlled environments, crucial for industries dependent on strict compliance and product integrity. Logistics automation streamlines operations by integrating technologies like robotics, IoT, and AI to enhance efficiency, reduce errors, and cut costs across supply chain processes. While cold chain management is essential for specific sectors requiring precise temperature control, logistics automation offers broader improvements in speed and accuracy across diverse logistics functions.

Connection

Cold chain management relies heavily on logistics automation to ensure precise temperature control and real-time monitoring during transportation and storage of perishable goods. Automated systems optimize route planning, inventory tracking, and environment adjustments, reducing spoilage and enhancing supply chain efficiency. Integration of IoT sensors and AI-driven analytics enables seamless coordination between cold storage units and distribution networks, maintaining product quality and compliance with regulations.

Key Terms

**Logistics Automation:**

Logistics automation leverages advanced technologies such as robotics, AI, and IoT to enhance supply chain efficiency, reduce human error, and accelerate order fulfillment processes. Integrating warehouse management systems (WMS) and automated guided vehicles (AGVs) optimizes inventory control and shipment accuracy, directly impacting cost reduction and delivery speed. Explore in-depth how logistics automation transforms operations and drives competitive advantage in modern supply chains.

Warehouse Management System (WMS)

Warehouse Management Systems (WMS) optimize logistics automation by streamlining inventory tracking, order fulfillment, and real-time data management to enhance operational efficiency. In cold chain management, WMS integrates temperature monitoring and compliance controls to ensure product integrity and regulatory adherence throughout storage and transit. Explore how advanced WMS solutions transform logistics and cold chain performance for improved supply chain reliability.

Automated Guided Vehicles (AGV)

Automated Guided Vehicles (AGVs) play a crucial role in logistics automation by enhancing material handling efficiency and reducing labor costs across various industries. In cold chain management, AGVs are specifically designed to maintain precise temperature control while transporting perishable goods, ensuring product integrity and compliance with safety standards. Explore how integrating AGVs can revolutionize both logistics automation and cold chain management for optimized supply chain performance.

Source and External Links

The Value of Logistics Automation in 2025 and Beyond - Logistics automation leverages technology like machinery and software to enhance procurement, manufacturing, inventory control, distribution, and customer support by automating routine tasks such as data entry, billing, and demand forecasting for increased efficiency and reduced errors.

Logistics automation - Wikipedia - Logistics automation applies automated machinery and software to warehouse operations including goods receipt, storage, retrieval, dispatch, and repackaging, reducing workforce needs and improving accuracy with tools like automated guided vehicles and pick-to-light systems.

A Guide to Logistics Automation - Logistics automation streamlines supply chain processes such as order processing, inventory management, and transportation scheduling to reduce costs, enhance accuracy, improve delivery speed, and provide real-time visibility across the supply chain.

dowidth.com

dowidth.com