Container pooling maximizes asset utilization by allowing multiple companies to share standardized containers, reducing empty miles and storage costs. Drop-and-hook enhances efficiency by enabling drivers to leave loaded trailers at a destination and immediately pick up preloaded ones, minimizing wait times and turnaround delays. Explore the key benefits and operational differences between container pooling and drop-and-hook strategies to optimize your supply chain logistics.

Why it is important

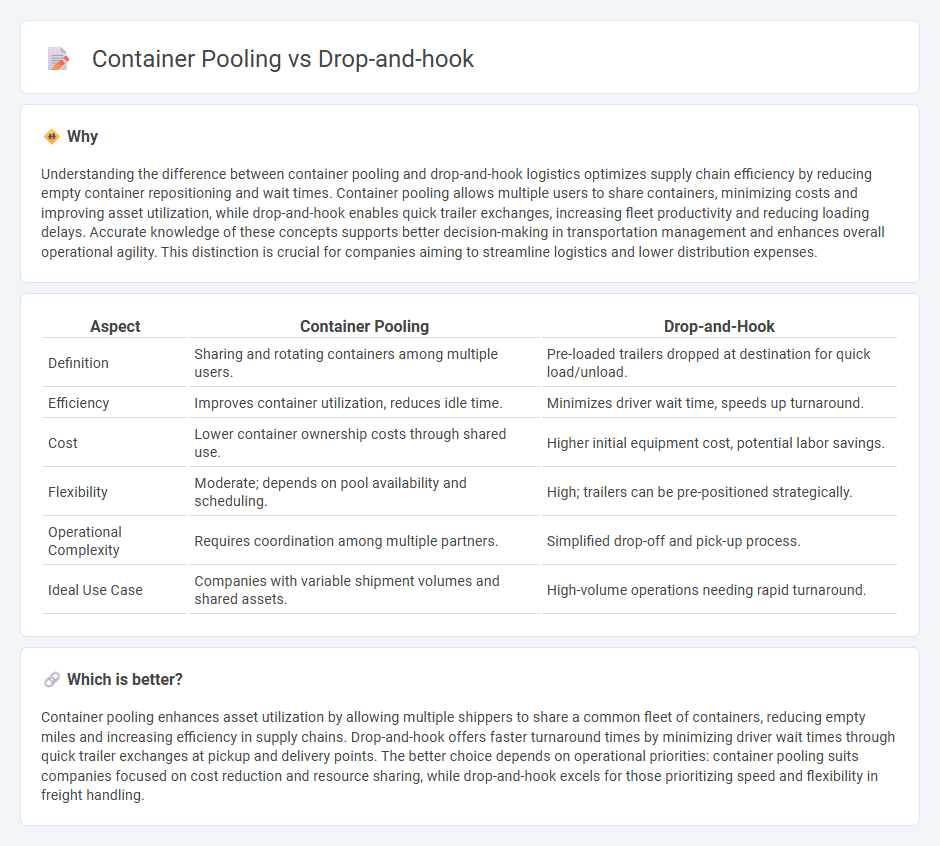

Understanding the difference between container pooling and drop-and-hook logistics optimizes supply chain efficiency by reducing empty container repositioning and wait times. Container pooling allows multiple users to share containers, minimizing costs and improving asset utilization, while drop-and-hook enables quick trailer exchanges, increasing fleet productivity and reducing loading delays. Accurate knowledge of these concepts supports better decision-making in transportation management and enhances overall operational agility. This distinction is crucial for companies aiming to streamline logistics and lower distribution expenses.

Comparison Table

| Aspect | Container Pooling | Drop-and-Hook |

|---|---|---|

| Definition | Sharing and rotating containers among multiple users. | Pre-loaded trailers dropped at destination for quick load/unload. |

| Efficiency | Improves container utilization, reduces idle time. | Minimizes driver wait time, speeds up turnaround. |

| Cost | Lower container ownership costs through shared use. | Higher initial equipment cost, potential labor savings. |

| Flexibility | Moderate; depends on pool availability and scheduling. | High; trailers can be pre-positioned strategically. |

| Operational Complexity | Requires coordination among multiple partners. | Simplified drop-off and pick-up process. |

| Ideal Use Case | Companies with variable shipment volumes and shared assets. | High-volume operations needing rapid turnaround. |

Which is better?

Container pooling enhances asset utilization by allowing multiple shippers to share a common fleet of containers, reducing empty miles and increasing efficiency in supply chains. Drop-and-hook offers faster turnaround times by minimizing driver wait times through quick trailer exchanges at pickup and delivery points. The better choice depends on operational priorities: container pooling suits companies focused on cost reduction and resource sharing, while drop-and-hook excels for those prioritizing speed and flexibility in freight handling.

Connection

Container pooling enhances logistics efficiency by enabling multiple shippers to share standardized containers, reducing empty container repositioning and lowering operational costs. Drop-and-hook workflows complement this system by allowing drivers to quickly exchange loaded and empty containers without waiting for loading or unloading, accelerating turnaround times. Together, container pooling and drop-and-hook streamline supply chain operations, boost asset utilization, and improve delivery reliability.

Key Terms

Trailer Utilization

Drop-and-hook operations enhance trailer utilization by enabling drivers to quickly swap trailers without waiting for loading or unloading, reducing downtime and increasing efficiency in freight transport. Container pooling optimizes asset usage by sharing containers among multiple users, minimizing empty container repositioning and maximizing container availability in supply chains. Explore how these logistics strategies impact trailer utilization and overall operational efficiency in transportation networks.

Asset Flexibility

Drop-and-hook offers asset flexibility by allowing trailers to be swapped quickly without waiting for unloading, maximizing fleet utilization and reducing idle times. Container pooling enables shared container assets across shippers, enhancing resource efficiency but often limiting individual asset control. Discover how each method impacts operational agility and cost management in your supply chain.

Turnaround Time

Drop-and-hook logistics significantly reduces turnaround time by enabling drivers to swap trailers quickly without waiting for loading or unloading processes. Container pooling streamlines container availability but may involve longer coordination, impacting overall dwell time. Explore the advantages of each method to optimize supply chain efficiency and minimize delays.

Source and External Links

Are Drop And Hooks Really Any Better Than Live Loads? - Drop and hook means a driver drops one trailer and hooks up to another, speeding up pickup and delivery by avoiding waiting for loading or unloading.

What Is Drop and Hook? Penske Logistics Glossary - Drop and hook is a process where a truck driver drops off a loaded trailer and hooks to a pre-loaded one, minimizing wait time and improving efficiency in the supply chain.

What is drop and hook trucking? - PLS Logistic Services - Drop and hook trucking refers to dropping off a full load and hooking up a preloaded or empty container without waiting for loading/unloading, thus saving driver time and increasing operational efficiency.

dowidth.com

dowidth.com