Supply chain control towers provide centralized visibility and real-time monitoring to improve decision-making across complex logistics networks. Logistics automation employs technology such as robotics and AI to streamline warehouse operations, reduce errors, and increase efficiency. Discover how integrating control towers with automation can transform supply chain performance.

Why it is important

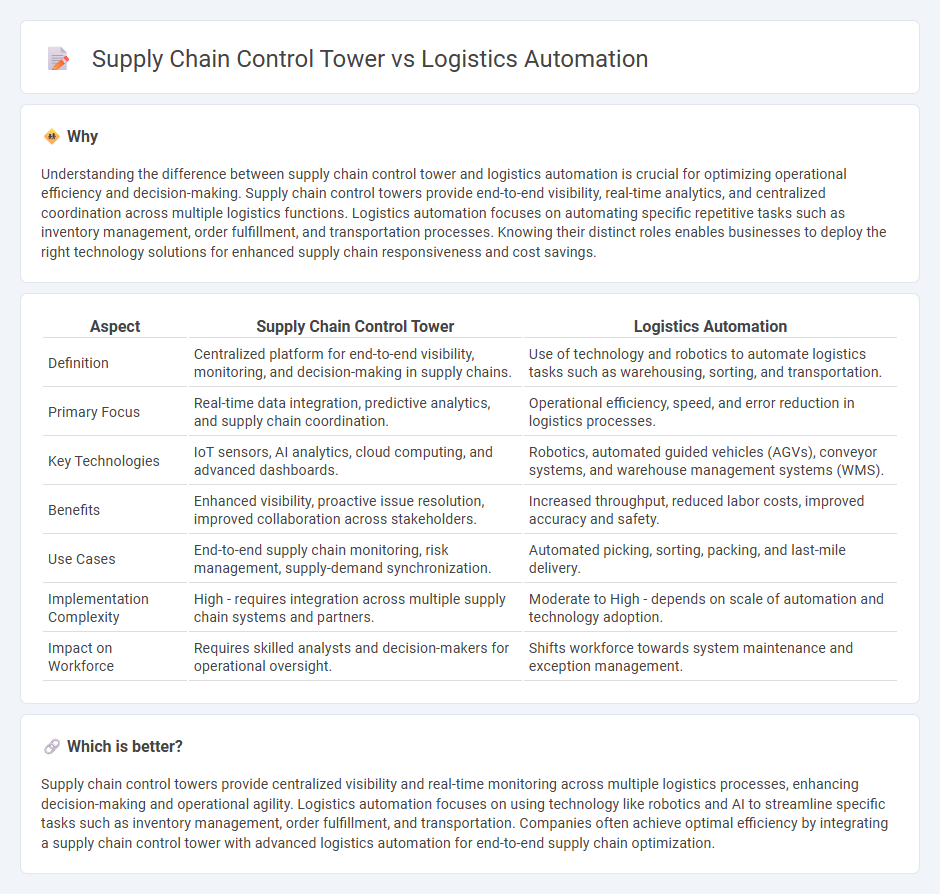

Understanding the difference between supply chain control tower and logistics automation is crucial for optimizing operational efficiency and decision-making. Supply chain control towers provide end-to-end visibility, real-time analytics, and centralized coordination across multiple logistics functions. Logistics automation focuses on automating specific repetitive tasks such as inventory management, order fulfillment, and transportation processes. Knowing their distinct roles enables businesses to deploy the right technology solutions for enhanced supply chain responsiveness and cost savings.

Comparison Table

| Aspect | Supply Chain Control Tower | Logistics Automation |

|---|---|---|

| Definition | Centralized platform for end-to-end visibility, monitoring, and decision-making in supply chains. | Use of technology and robotics to automate logistics tasks such as warehousing, sorting, and transportation. |

| Primary Focus | Real-time data integration, predictive analytics, and supply chain coordination. | Operational efficiency, speed, and error reduction in logistics processes. |

| Key Technologies | IoT sensors, AI analytics, cloud computing, and advanced dashboards. | Robotics, automated guided vehicles (AGVs), conveyor systems, and warehouse management systems (WMS). |

| Benefits | Enhanced visibility, proactive issue resolution, improved collaboration across stakeholders. | Increased throughput, reduced labor costs, improved accuracy and safety. |

| Use Cases | End-to-end supply chain monitoring, risk management, supply-demand synchronization. | Automated picking, sorting, packing, and last-mile delivery. |

| Implementation Complexity | High - requires integration across multiple supply chain systems and partners. | Moderate to High - depends on scale of automation and technology adoption. |

| Impact on Workforce | Requires skilled analysts and decision-makers for operational oversight. | Shifts workforce towards system maintenance and exception management. |

Which is better?

Supply chain control towers provide centralized visibility and real-time monitoring across multiple logistics processes, enhancing decision-making and operational agility. Logistics automation focuses on using technology like robotics and AI to streamline specific tasks such as inventory management, order fulfillment, and transportation. Companies often achieve optimal efficiency by integrating a supply chain control tower with advanced logistics automation for end-to-end supply chain optimization.

Connection

A supply chain control tower enhances logistics operations by providing real-time visibility, predictive analytics, and centralized decision-making across the entire supply chain. Logistics automation integrates with control towers through technologies like IoT sensors, robotics, and AI-driven workflows to streamline material handling, order processing, and inventory management. This synergy enables faster response times, reduces errors, and optimizes resource allocation throughout logistics networks.

Key Terms

Robotics Process Automation (RPA)

Logistics automation leverages Robotics Process Automation (RPA) to streamline repetitive tasks such as order processing, inventory management, and shipment tracking, significantly reducing human error and operational costs. Supply chain control towers utilize RPA to enhance real-time visibility and decision-making by integrating data from diverse supply chain nodes, enabling proactive responses to disruptions. Explore how RPA can transform your logistics and supply chain control strategies by diving deeper into their comparative benefits.

End-to-End Visibility

Logistics automation streamlines warehouse operations and transportation through robotics and AI to enhance efficiency and accuracy. Supply chain control towers provide end-to-end visibility by integrating real-time data from multiple sources for proactive decision-making and risk management. Explore how these technologies transform supply chain transparency and performance in more detail.

Real-Time Analytics

Logistics automation streamlines operational tasks such as inventory management, order processing, and transportation through technologies like robotics and AI, enhancing efficiency at the warehouse level. Supply chain control towers provide a centralized platform that leverages real-time analytics to monitor, predict, and respond to supply chain disruptions, delivering end-to-end visibility across multiple logistics partners and stages. Explore the differences to understand how integrating both systems can optimize your supply chain performance.

Source and External Links

The Value of Logistics Automation in 2025 and Beyond - Logistics automation involves using specialized machinery and software to enhance logistics processes such as procurement, inventory control, distribution, and returns management through techniques like automatic data entry, computerized picking, and predictive demand forecasting.

Logistics automation - Wikipedia - It is the application of computer software or automated machinery to improve efficiency in warehouses and distribution centers by automating goods receipt, storage, retrieval, dispatch processing, and reducing labor through systems like automated storage and retrieval and Automatic Guided Vehicles (AGVs).

A Guide to Logistics Automation - Logistics automation streamlines order processing, inventory management, and transportation scheduling to reduce costs and errors, improve speed and accuracy, and provide real-time visibility in the supply chain to meet customer expectations and operational challenges.

dowidth.com

dowidth.com