Predictive fleet maintenance uses real-time data and advanced analytics to anticipate vehicle issues before they cause breakdowns, reducing downtime and repair costs. Capacity planning focuses on optimizing resource allocation to meet demand efficiently by forecasting fleet size and utilization needs. Explore how integrating predictive maintenance with capacity planning can significantly enhance logistics performance and operational efficiency.

Why it is important

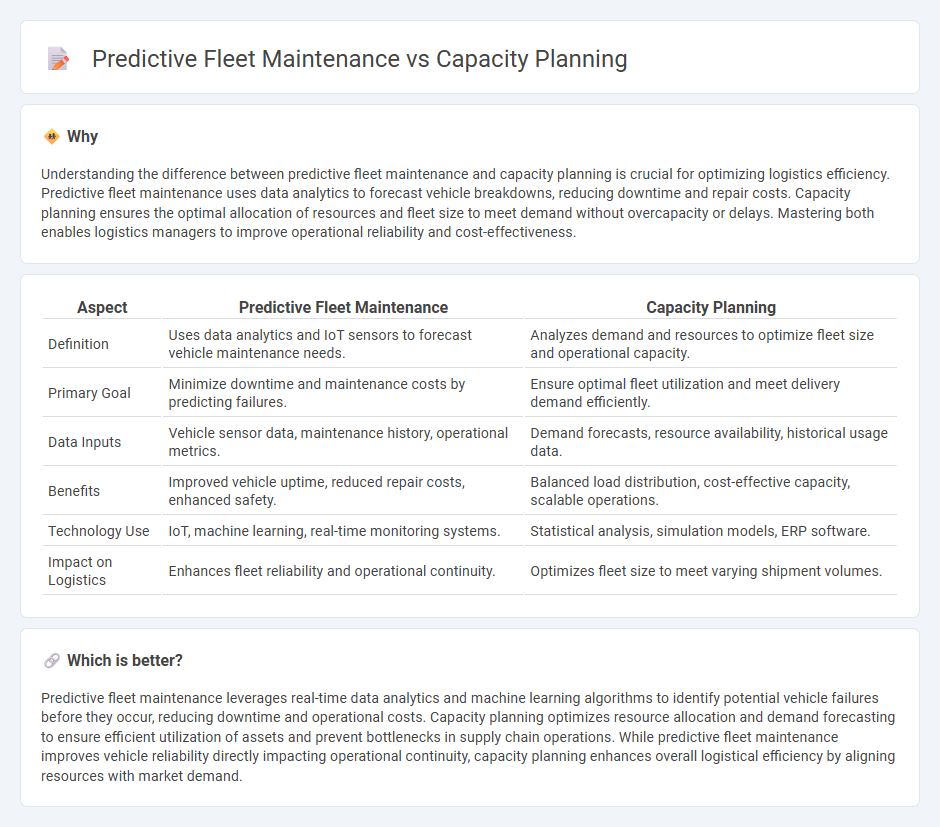

Understanding the difference between predictive fleet maintenance and capacity planning is crucial for optimizing logistics efficiency. Predictive fleet maintenance uses data analytics to forecast vehicle breakdowns, reducing downtime and repair costs. Capacity planning ensures the optimal allocation of resources and fleet size to meet demand without overcapacity or delays. Mastering both enables logistics managers to improve operational reliability and cost-effectiveness.

Comparison Table

| Aspect | Predictive Fleet Maintenance | Capacity Planning |

|---|---|---|

| Definition | Uses data analytics and IoT sensors to forecast vehicle maintenance needs. | Analyzes demand and resources to optimize fleet size and operational capacity. |

| Primary Goal | Minimize downtime and maintenance costs by predicting failures. | Ensure optimal fleet utilization and meet delivery demand efficiently. |

| Data Inputs | Vehicle sensor data, maintenance history, operational metrics. | Demand forecasts, resource availability, historical usage data. |

| Benefits | Improved vehicle uptime, reduced repair costs, enhanced safety. | Balanced load distribution, cost-effective capacity, scalable operations. |

| Technology Use | IoT, machine learning, real-time monitoring systems. | Statistical analysis, simulation models, ERP software. |

| Impact on Logistics | Enhances fleet reliability and operational continuity. | Optimizes fleet size to meet varying shipment volumes. |

Which is better?

Predictive fleet maintenance leverages real-time data analytics and machine learning algorithms to identify potential vehicle failures before they occur, reducing downtime and operational costs. Capacity planning optimizes resource allocation and demand forecasting to ensure efficient utilization of assets and prevent bottlenecks in supply chain operations. While predictive fleet maintenance improves vehicle reliability directly impacting operational continuity, capacity planning enhances overall logistical efficiency by aligning resources with market demand.

Connection

Predictive fleet maintenance utilizes data analytics and IoT sensors to anticipate vehicle failures, ensuring minimal downtime and optimized operational efficiency. By integrating predictive maintenance insights with capacity planning, logistics managers can better allocate resources and schedule fleet usage based on vehicle availability and reliability forecasts. This synergy enhances fleet utilization rates, reduces unexpected maintenance costs, and improves overall supply chain responsiveness.

Key Terms

**Capacity Planning:**

Capacity planning involves analyzing current and future resource requirements to ensure optimal utilization of assets, workforce, and materials in logistics and manufacturing. It leverages historical data, demand forecasting, and scenario analysis to prevent bottlenecks and maximize operational efficiency. Explore detailed strategies and tools to enhance your capacity planning accuracy and effectiveness.

Demand Forecasting

Capacity planning leverages demand forecasting to allocate resources efficiently, ensuring fleet availability aligns with anticipated service needs. Predictive fleet maintenance uses sensor data and analytics to forecast vehicle failures and schedule timely interventions, minimizing downtime and optimizing operational capacity. Explore how integrating demand forecasting enhances both capacity planning and predictive maintenance for superior fleet management.

Resource Allocation

Capacity planning ensures optimal resource allocation by forecasting demand and aligning workforce, equipment, and materials to meet production goals efficiently. Predictive fleet maintenance leverages data analytics to anticipate vehicle service needs, minimizing downtime and preventing resource overuse for unexpected repairs. Explore how integrating these strategies enhances operational efficiency and resource management.

Source and External Links

What Is Capacity Planning? - IBM - Capacity planning is a strategic process that aligns an organization's resources with current and future demand to optimize operational efficiency.

What Is Capacity Planning and Should You Use It? [2025] - Capacity planning is a proactive method to assess and prepare resources needed to meet current demand and projected needs, ensuring efficient workflows.

Capacity planning - Wikipedia - Capacity planning is the process of determining the production capacity required by an organization to meet changing demands for its products.

dowidth.com

dowidth.com