Cold chain visibility provides real-time tracking and monitoring of temperature-sensitive shipments to ensure product integrity throughout the supply chain. Cold chain analytics leverages collected data to identify patterns, optimize routes, and predict potential disruptions, enhancing overall efficiency and compliance. Explore the differences and benefits of visibility and analytics to improve your cold chain operations.

Why it is important

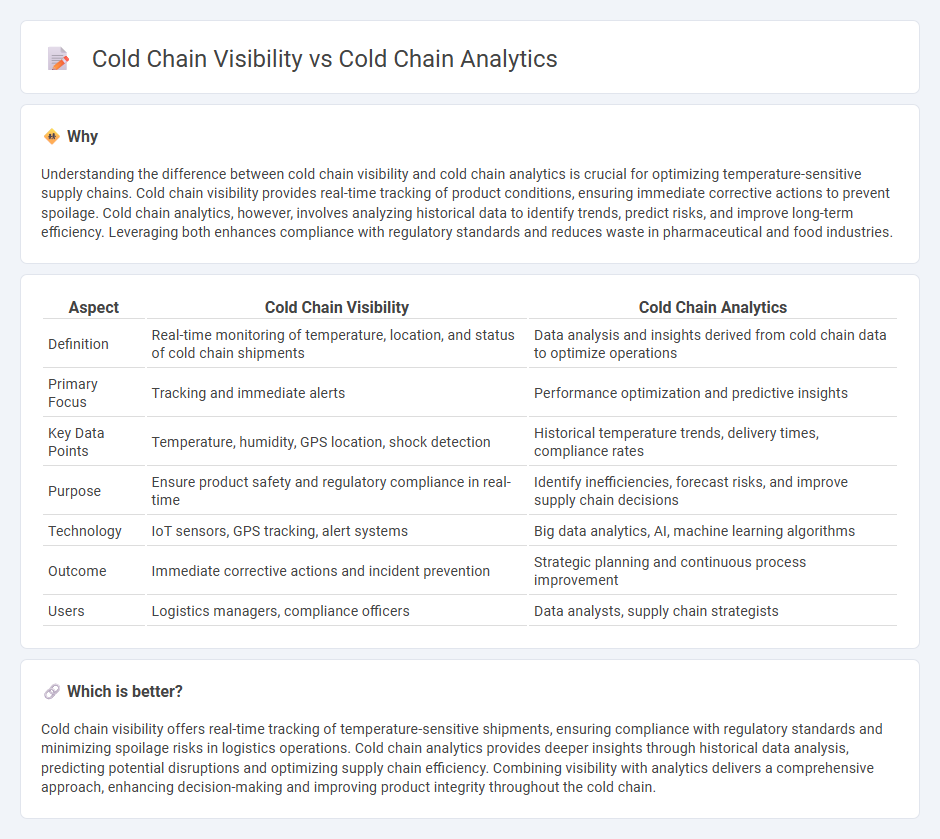

Understanding the difference between cold chain visibility and cold chain analytics is crucial for optimizing temperature-sensitive supply chains. Cold chain visibility provides real-time tracking of product conditions, ensuring immediate corrective actions to prevent spoilage. Cold chain analytics, however, involves analyzing historical data to identify trends, predict risks, and improve long-term efficiency. Leveraging both enhances compliance with regulatory standards and reduces waste in pharmaceutical and food industries.

Comparison Table

| Aspect | Cold Chain Visibility | Cold Chain Analytics |

|---|---|---|

| Definition | Real-time monitoring of temperature, location, and status of cold chain shipments | Data analysis and insights derived from cold chain data to optimize operations |

| Primary Focus | Tracking and immediate alerts | Performance optimization and predictive insights |

| Key Data Points | Temperature, humidity, GPS location, shock detection | Historical temperature trends, delivery times, compliance rates |

| Purpose | Ensure product safety and regulatory compliance in real-time | Identify inefficiencies, forecast risks, and improve supply chain decisions |

| Technology | IoT sensors, GPS tracking, alert systems | Big data analytics, AI, machine learning algorithms |

| Outcome | Immediate corrective actions and incident prevention | Strategic planning and continuous process improvement |

| Users | Logistics managers, compliance officers | Data analysts, supply chain strategists |

Which is better?

Cold chain visibility offers real-time tracking of temperature-sensitive shipments, ensuring compliance with regulatory standards and minimizing spoilage risks in logistics operations. Cold chain analytics provides deeper insights through historical data analysis, predicting potential disruptions and optimizing supply chain efficiency. Combining visibility with analytics delivers a comprehensive approach, enhancing decision-making and improving product integrity throughout the cold chain.

Connection

Cold chain visibility leverages real-time tracking technologies to monitor temperature-sensitive products throughout the logistics process, ensuring compliance with regulatory standards and preserving product integrity. Cold chain analytics processes this visibility data using advanced algorithms to identify patterns, predict risks, and optimize routes for enhanced efficiency and reduced spoilage. Integrating both technologies results in proactive decision-making, minimizing losses and improving customer satisfaction within the cold chain logistics sector.

Key Terms

Cold Chain Analytics:

Cold Chain Analytics leverages data from temperature sensors, GPS trackers, and IoT devices to monitor and optimize the entire cold chain process, ensuring product integrity and regulatory compliance. By analyzing trends in temperature fluctuations and transit times, businesses can proactively address risks, reduce spoilage, and improve supply chain efficiency. Discover how advanced Cold Chain Analytics transforms perishable goods management for better decision-making and cost savings.

Predictive Analytics

Cold chain analytics harnesses advanced predictive analytics to forecast potential disruptions, optimize temperature control, and improve inventory management, thereby enhancing supply chain efficiency and reducing spoilage risk. Cold chain visibility provides real-time tracking and monitoring of cold chain conditions but lacks the predictive capacity to anticipate future issues and enable proactive decision-making. Explore how predictive analytics in cold chain analytics transforms supply chain management for better reliability and cost savings.

Data Integration

Cold chain analytics leverages advanced data integration techniques to collect, process, and analyze temperature, humidity, and location data from diverse sources, providing actionable insights to optimize product quality and reduce spoilage. Cold chain visibility focuses primarily on real-time tracking and monitoring of shipments, emphasizing data integration for seamless information flow across supply chain stakeholders. Explore how integrating robust data systems enhances both analytics and visibility to improve cold chain efficiency and compliance.

Source and External Links

Predictive analytics in cold chain logistics: how does it work? - Predictive analytics uses historical and real-time data with machine learning to forecast demand, detect anomalies, and prevent cold chain disruptions, improving inventory control, maintenance, and sustainability in cold chain operations.

Leveraging Data Analytics to Improve Cold Chain Performance - Data analytics including IoT sensor monitoring and predictive models help businesses maintain optimal temperature and humidity, foresee equipment failures, optimize routing, and enhance overall cold chain reliability and efficiency.

How IoT Analytics Are Transforming Cold Chain Efficiency - IoT-based predictive analytics significantly improve cold chain efficiency by preventing spoilage through temperature monitoring and by optimizing logistics, contributing to a rapidly growing cold chain logistics market.

dowidth.com

dowidth.com